Preparation method of fermented protein feed and fermented protein feed

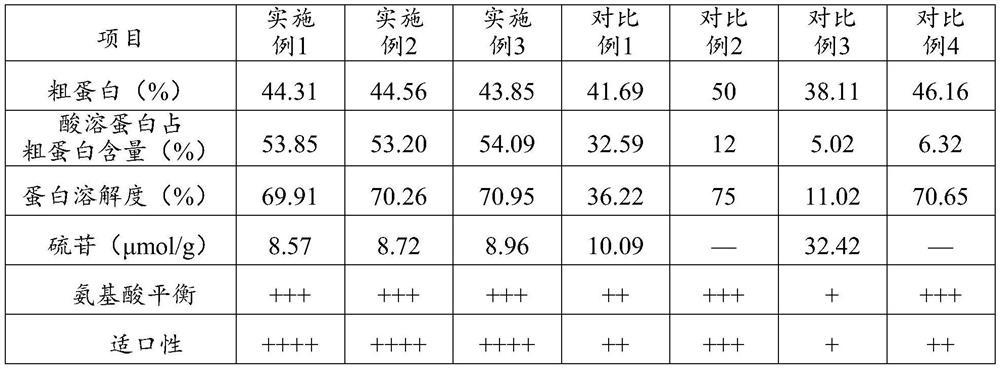

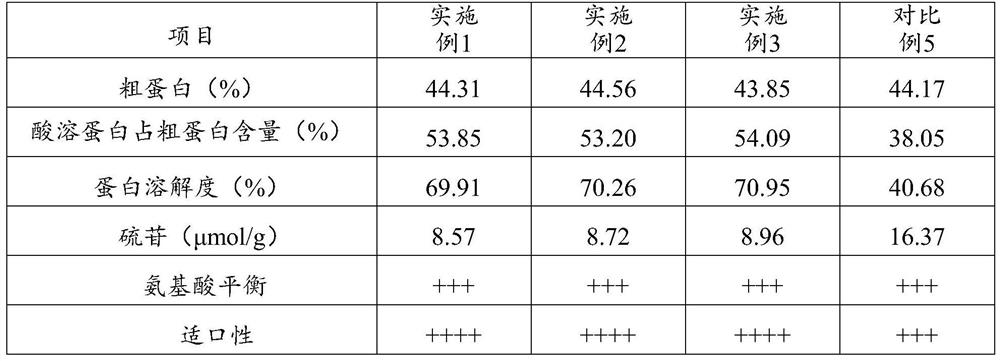

A technology of fermented protein feed and fermented material, which is applied in the field of biological fermented feed, can solve the problem of acid-soluble protein content, protein solubility, removal of toxic and anti-nutritional components, unsatisfactory amino acid balance and palatability, difficulty in adapting to the strong demand for protein feed, fermentation The temperature is difficult to control and other problems, to achieve the effect of inhibiting the growth and reproduction of miscellaneous bacteria, improving the palatability of feed, and increasing the content of acid-soluble protein

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of fermented protein feed, comprises the following steps:

[0027] 1) protein raw material, water, Tween 80 and peracetic acid solution are mixed, obtain mixed material; Described protein raw material comprises rapeseed meal, soybean meal and corn gluten meal; The quality of described rapeseed meal, soybean meal and corn gluten meal The ratio is (70~80):(10~30):(2~5);

[0028] 2) Inoculate Aspergillus oryzae in the mixed material obtained in the step 1), and perform solid-state aerobic fermentation to obtain a fermented material; the temperature of the solid-state aerobic fermentation is 28-32°C; the time of the solid-state aerobic fermentation 32~36h;

[0029] 3) After mixing the fermented material obtained in step 2) with Enterococcus faecium culture solution and water, carry out anaerobic fermentation and enzymolysis to obtain fermented protein feed; the temperature of the anaerobic fermentation and enzymolysis is ...

Embodiment 1

[0055] 1) Weigh 100kg of 40°C warm water, 800.5kg of Tween, 1.0kg of 16% peracetic acid solution (16% by mass), 80kg of rapeseed meal, 15kg of soybean meal and 5kg of corn gluten powder. Warm water, Tween 80, and peracetic acid solution were mixed evenly, and then mixed with the protein material, and left to moisten the material for 50 minutes to obtain the mixed material;

[0056] 2) Insert Aspergillus oryzae into the mixed material according to the inoculation amount of 2.5%, fully mix, control the thickness of the material to 30cm, carry out solid-state aerobic fermentation, the fermentation temperature is 28 ° C, ferment for 36 hours, and turn the material once every 8 hours during the period to obtain fermentation material;

[0057] 3) Fermented material and Enterococcus faecium culture solution (bacterial content of Enterococcus faecium ≥ 3.5×10 9 cfu / ml) according to the mass ratio of 100:0.5, after fully mixing, control the water content in the fermentation material t...

Embodiment 2

[0059] 1) Weigh 100kg of 60°C warm water, 801.5kg of Tween, 0.88kg of 16% peracetic acid solution (mass percentage content is 16%), 70kg of rapeseed meal, 28kg of soybean meal, and 2kg of corn gluten powder. Warm water was mixed with Tween 80 and peracetic acid solution, then mixed with protein raw material, and left to moisten the material for 20 minutes to obtain the mixed material;

[0060] 2) Insert Aspergillus oryzae into the mixed material according to the inoculation amount of 3.0%, fully mix, control the thickness of the material to 20cm, carry out solid-state aerobic fermentation, the fermentation temperature is 32°C, ferment for 32h, and turn the material once every 12h during the period to obtain fermentation material;

[0061] 3) Fermented material and bacterial culture solution (bacterial content of Enterococcus faecium ≥ 3.5×10 9 cfu / ml) according to the mass ratio of 100:1, after fully mixing, control the water content of the fermentation material to 50%, carry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com