Catalytic combustion treatment method for chlorine-containing organic waste gas

A catalytic combustion and organic waste gas technology, applied in the direction of combustion methods, chemical instruments and methods, combustion types, etc., can solve the problems of increased processing costs, lye consumption, pipeline corrosion, etc., to achieve long service life and increase coating volume , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

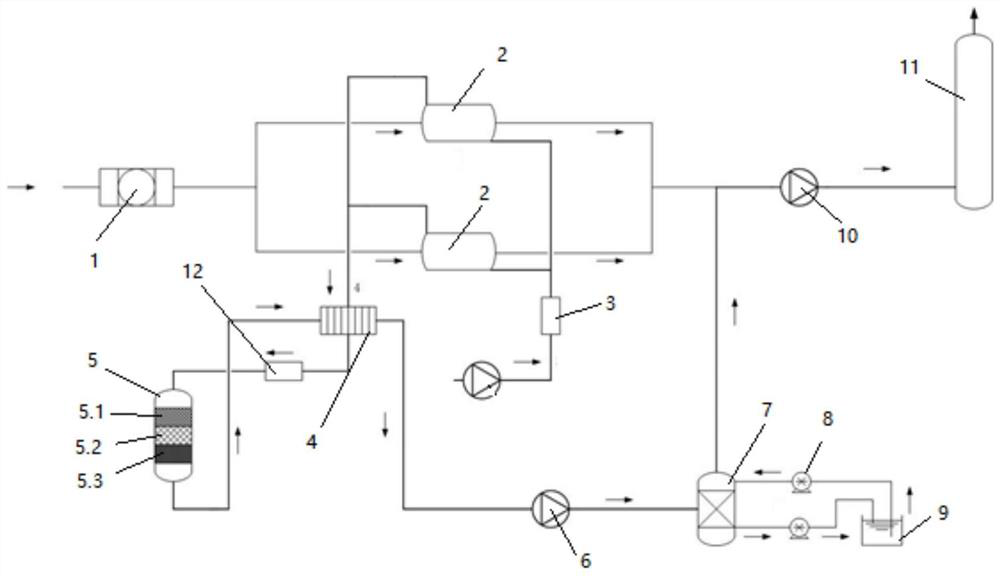

Method used

Image

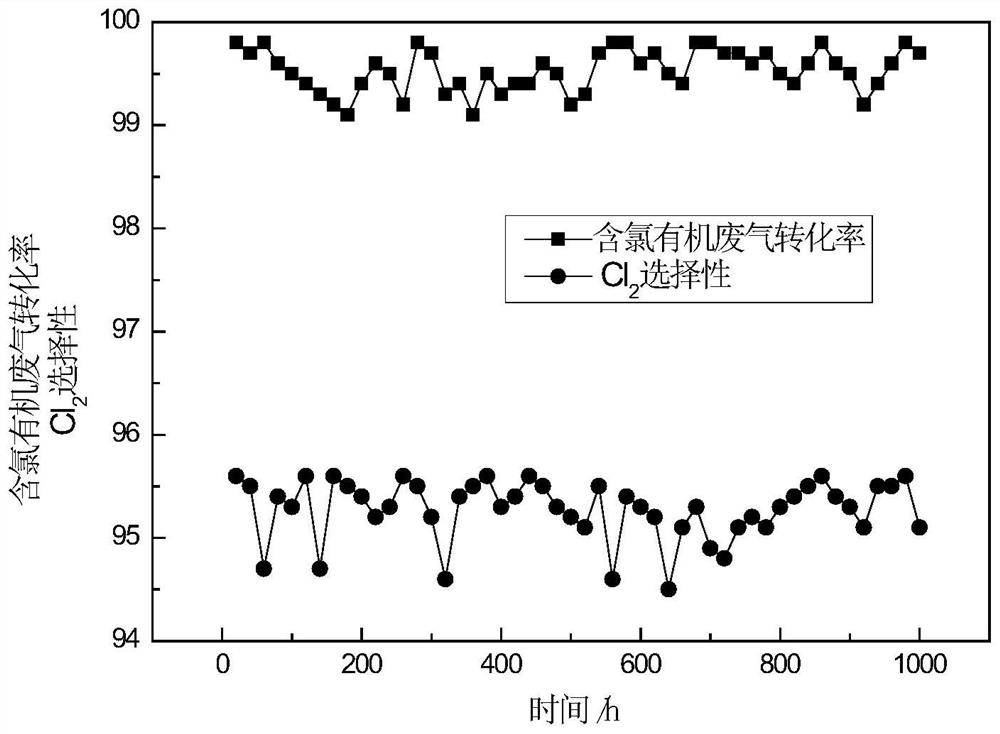

Examples

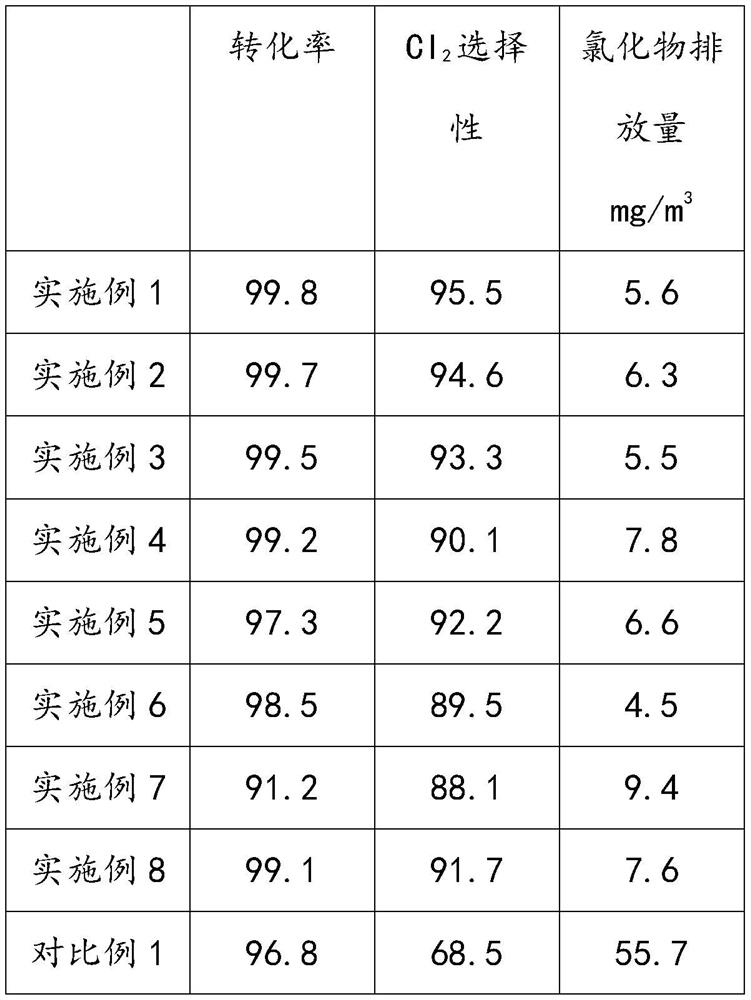

Embodiment 1

[0036] Preparation of Catalyst A:

[0037] Pretreatment of the second carrier cordierite honeycomb ceramics: soak the cordierite honeycomb ceramic carrier in dilute nitric acid with a mass concentration of 5% for 2 hours, then wash with deionized water for 3 times, and dry at 120°C for 10 hours to obtain surface-activated cordierite. Bluestone Honeycomb Ceramics.

[0038] Preparation of the first carrier: The carrier is prepared by co-precipitation method. Measure 1L of a mixed solution of 0.2mol / L cerium nitrate, 0.075mol / L zirconium nitrate, and 0.15mol / L aluminum nitrate, and add a mass concentration of 2wt dropwise while stirring at 80°C. % sodium carbonate solution, maintain the pH value of the solution at 10, continue to stir for 8 hours, age for 12 hours, then filter with suction, and wash the precipitate with deionized water until it becomes neutral. The filter cake was dried at 110°C for 12h and calcined at 500°C for 5h to obtain a CeZrAl carrier, wherein the Ce:Zr:A...

Embodiment 2

[0055] Preparation of Catalyst A:

[0056] Pretreatment of the second carrier cordierite honeycomb ceramics: the same pretreatment method as the second carrier cordierite honeycomb ceramics in Catalyst A of Example 1.

[0057] Preparation of the first carrier: the carrier is prepared by co-precipitation method, measure 1L of a mixed solution of 0.2mol / L cerium nitrate, 0.1mol / L zirconium nitrate, and 0.15mol / L aluminum nitrate, and add a mass concentration of 2wt dropwise while stirring at 80°C % sodium carbonate solution, maintain the pH value of the solution at 10, continue to stir for 8 hours, age for 12 hours, then filter with suction, and wash the precipitate with deionized water until it becomes neutral. The filter cake was dried at 110°C for 12h and calcined at 550°C for 5h to obtain a CeZrAl carrier, wherein the molar ratio of Ce:Zr:Al was 4:2:3.

[0058] Preparation of powder catalyst: Measure 50mL of 0.128mol / L chromium nitrate solution, 100mL of 0.328mol / L manganes...

Embodiment 3

[0072] Catalyst preparation:

[0073] The second carrier cordierite honeycomb ceramic pretreatment:

[0074] The pretreatment method of the second carrier cordierite honeycomb ceramics in catalyst A of Example 1 is the same.

[0075] Preparation of the first carrier: The carrier is prepared by co-precipitation method. Measure 1L of a mixed solution of 0.2mol / L cerium nitrate, 0.08mol / L zirconium nitrate, and 0.08mol / L aluminum nitrate, and add a mass concentration of 2wt dropwise while stirring at 80°C. % sodium hydroxide solution, maintain the pH value of the solution at 10, continue to stir for 8 hours, age for 12 hours, then filter with suction, and wash the precipitate with deionized water until it becomes neutral. The filter cake was dried at 110°C for 12h and calcined at 500°C for 5h to obtain a CeZrAl carrier, wherein the molar ratio of Ce:Zr:Al was 5:2:2.

[0076] Preparation of powder catalyst: Measure 50mL of 0.128mol / L chromium nitrate solution, 100mL of 0.256mol / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com