Dimethylamine waste gas treatment device and process in synthetic leather industry

A technology of exhaust gas treatment and dimethylamine, which is applied in the direction of combined devices, gas treatment, air quality improvement, etc., can solve the problems of the surrounding environment and the living population, the environmental impact of dimethylamine exhaust gas, and human health hazards, so as to avoid sparks Effects of discharge phenomenon, reduction of ineffective heat release, and improvement of discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing, the present invention is further analyzed.

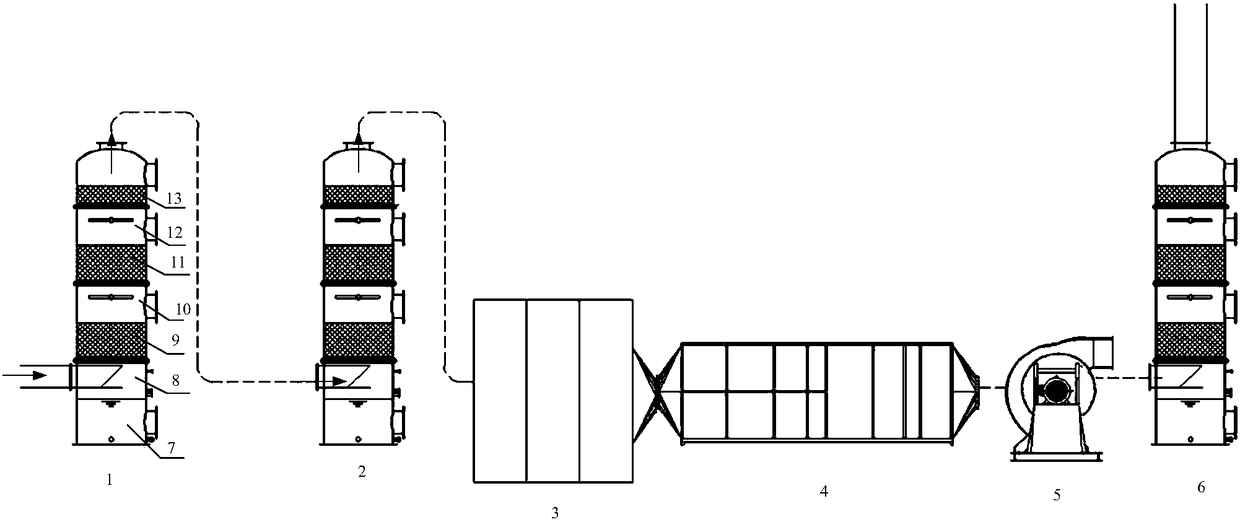

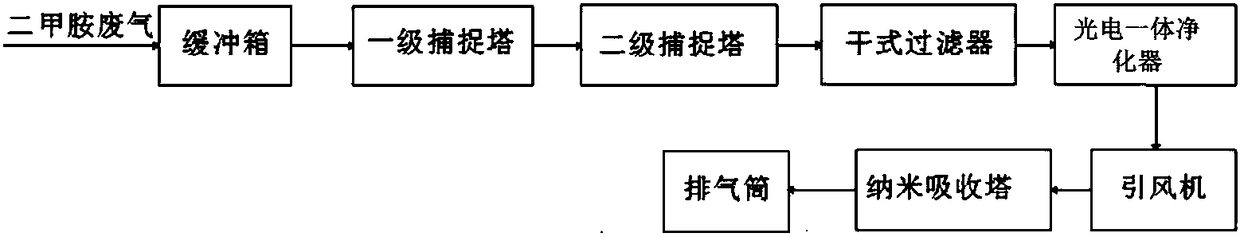

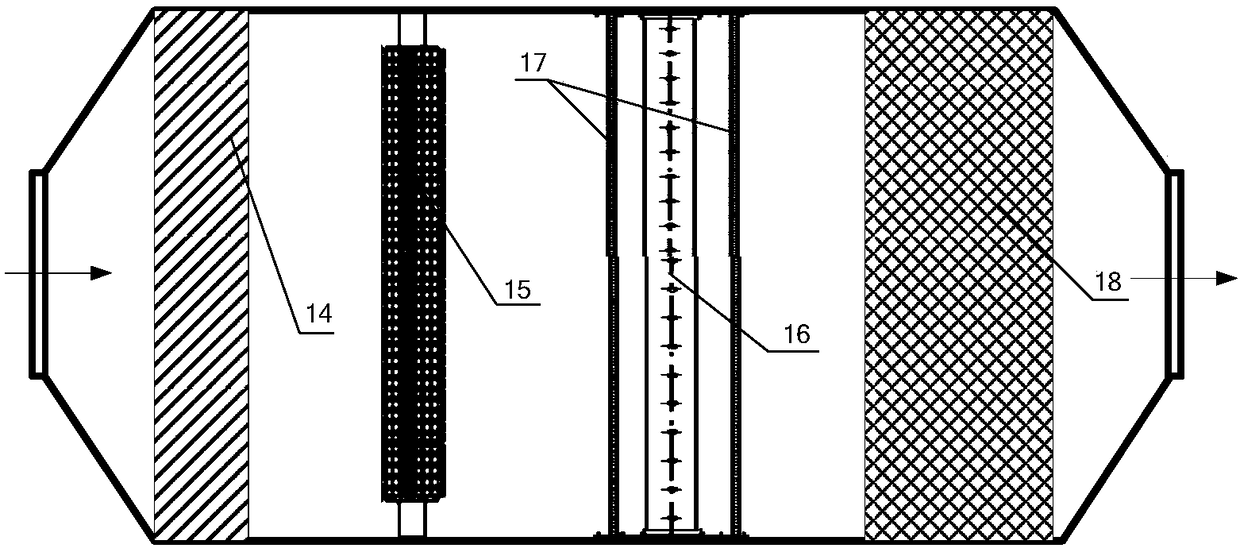

[0045] like figure 1 As shown, the dimethylamine waste gas treatment device in the synthetic leather industry includes a primary capture tower 1, a secondary capture tower 2, a dry filter 3, a photoelectric integrated purifier 4, and a nano-absorption tower 6; the air outlet of the primary capture tower Connect the air inlet of the secondary capture tower through the pipeline, the air outlet of the secondary capture tower is connected with the air inlet of the dry filter through the pipeline, and the air outlet of the dry filter is connected with the air inlet of the photoelectric integrated purifier. The air outlet of the photoelectric integrated purifier is connected with the air inlet of the nano absorption tower through a pipeline, and an induced draft fan 5 is arranged on the pipeline between the photoelectric integrated purifier and the nano absorption tower.

[0046] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com