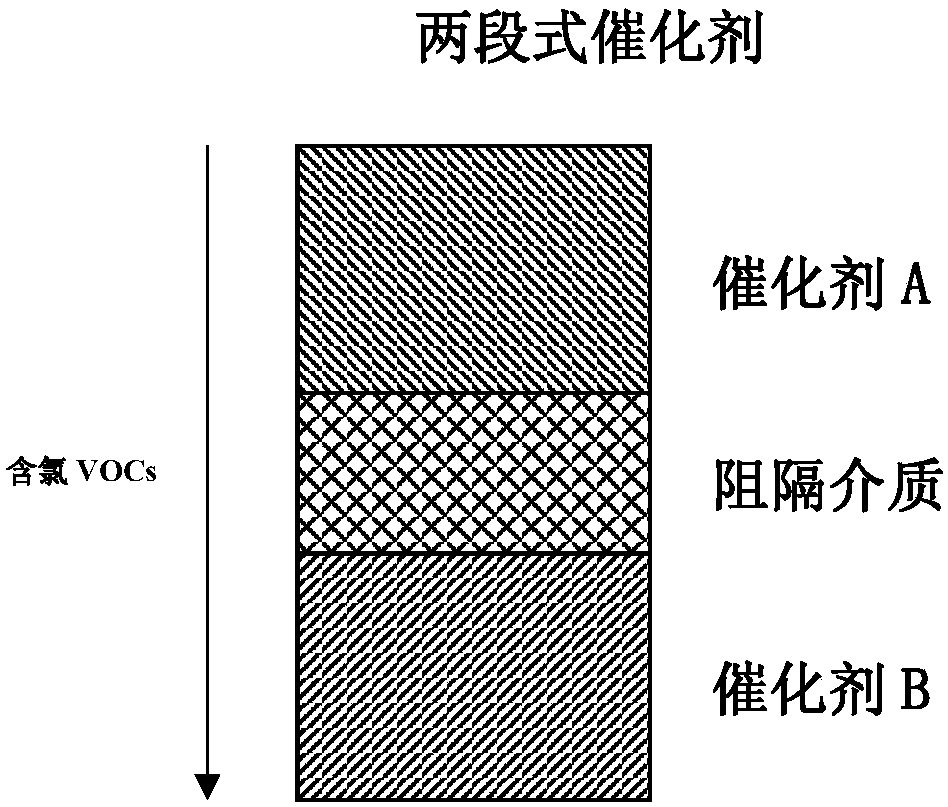

Two-stage catalyst for catalytic degradation of chlorine-containing volatile organic chemicals (VOCs) as well as preparation method and application of two-stage catalyst

A catalytic degradation and catalyst technology, applied in the field of catalysis, can solve the problems of increasing process complexity, application limitation, incomplete catalytic oxidation, etc., and achieves the solution of deep oxidation and catalyst chlorine poisoning, good anti-chlorine poisoning performance, and excellent catalytic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

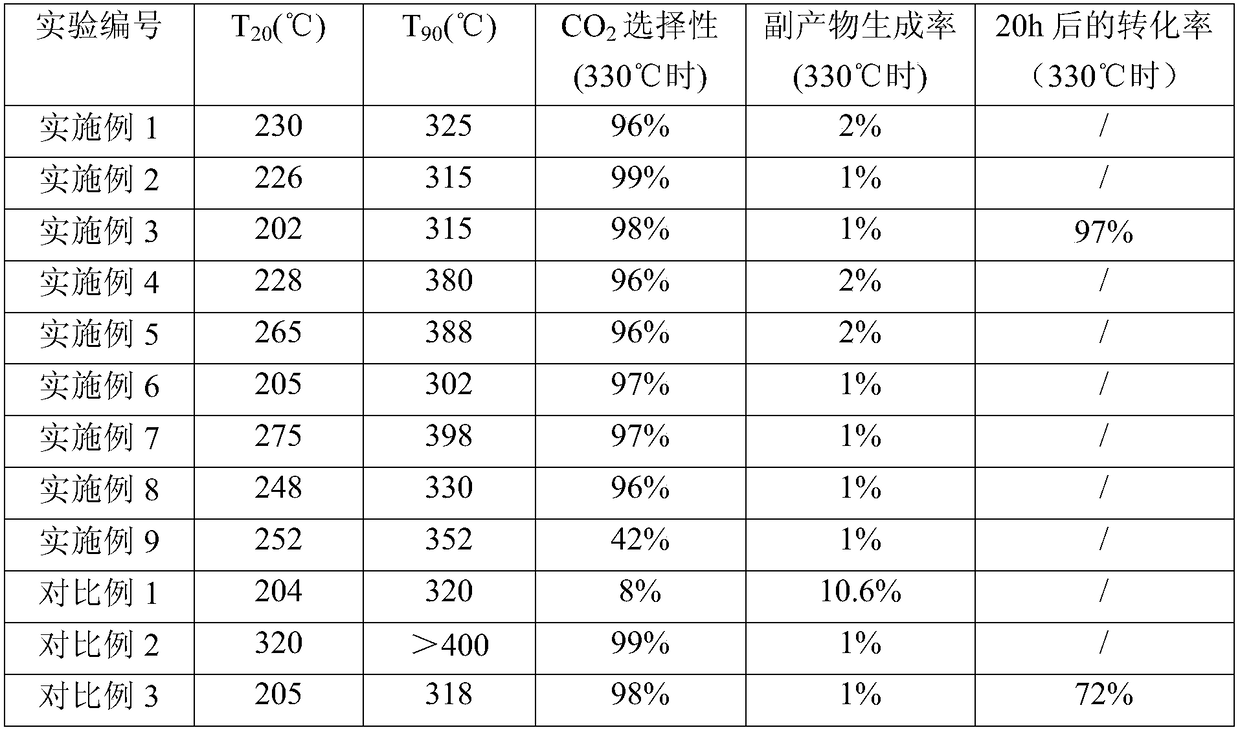

Embodiment 1

[0038] Example 1: Cr / TiO 2 -Cu / CeO 2

[0039] Preparation of Catalyst A: Pipette a certain amount of chromium nitrate solution into P25 (commercially available titanium dioxide) (the mass ratio of chromium and titanium is 1:18), stir vigorously for 3 hours, then put it in an oven and dry it at 80°C for 12 hours, and then transfer it to the Calcined at 450°C for 3h in a Furnace.

[0040] Preparation of catalyst B: Calcining cerium nitrate in a muffle furnace at 450°C for 3h to obtain pure CeO 2 . Dissolve the copper nitrate solution in deionized water, add cerium oxide (the mass ratio of copper to cerium is 1:7), stir for 3 hours, then put it in an oven for 12 hours at 80°C, and then transfer it to a muffle furnace for 3 hours at 450°C. .

[0041]Catalytic combustion performance test of the catalyst: Sieve the finished catalysts A and B prepared above to 40-60 mesh, take 0.6ml each, mix them with equal volume of quartz sand, put them into a quartz reaction tube, and use 0....

Embodiment 2

[0042] Example 2: CeO 2 / TiO 2 -CuCl 2 / CeO 2

[0043] Preparation of catalyst A: preparation of granular TiO by hydrothermal method 2 , cerium nitrate was calcined in a muffle furnace at 450°C for 3h to obtain pure CeO 2 . CeO 2 and TiO 2 Mix according to a certain ratio (mass ratio of cerium and titanium is 3:1), ball mill for 2 hours, transfer to a muffle furnace and bake at 450°C for 3 hours, and finally press into tablets and sieve.

[0044] Preparation of catalyst B: Calcining cerium nitrate in a muffle furnace at 450°C for 3h to obtain pure CeO 2 . CuCl 2 and CeO 2 Mix according to a certain ratio (mass ratio of copper to cerium is 1:2), ball mill for 2 hours, put in a muffle furnace for 3 hours at 400°C, and finally press into tablets and sieve.

[0045] Catalytic combustion performance test of the catalyst: Sieve the finished catalysts A and B prepared above to 40-60 mesh, take 0.6ml each, mix them with equal volume of quartz sand, put them into a quartz r...

Embodiment 3

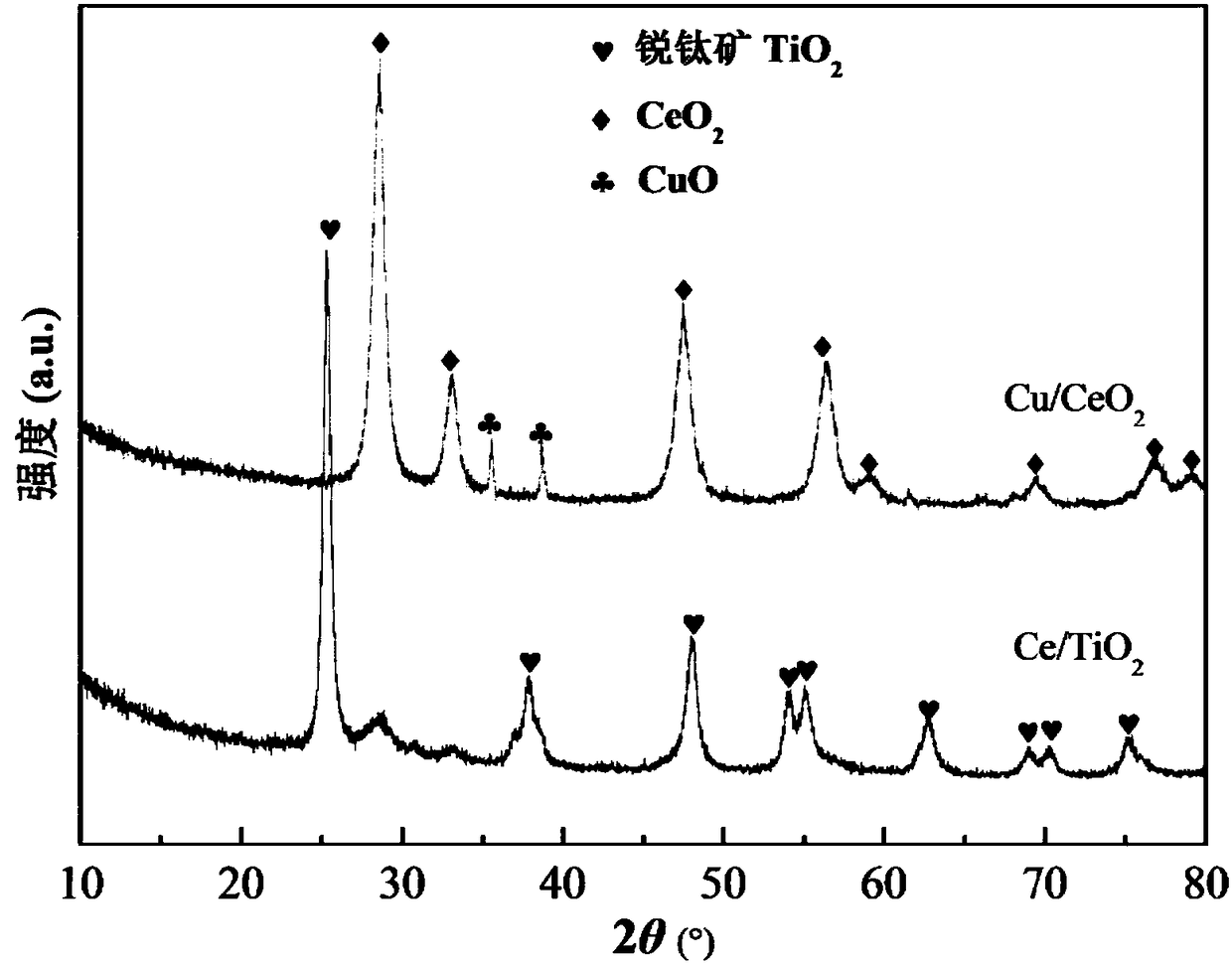

[0046] Example 3: Ce / TiO 2 -Cu / CeO 2

[0047] Preparation of Catalyst A: Pipette a certain amount of cerium nitrate solution into titanium dioxide prepared by hydrothermal method (mass ratio of cerium to titanium: 1:6), stir vigorously for 3 hours, then put it in an oven for 12 hours at 80°C, and then transfer it into the muffle Baking in the furnace at 450°C for 3h.

[0048] Preparation of catalyst B: Calcining cerium nitrate in a muffle furnace at 450°C for 3h to obtain pure CeO 2 . Dissolve the copper chloride solution in deionized water, add cerium oxide (the mass ratio of copper to cerium is 1:7), stir for 3 hours, then put it in an oven for 12 hours at 80°C, and then transfer it to a muffle furnace for roasting at 400°C 3h.

[0049] Catalytic combustion performance test of the catalyst: Sieve the finished catalysts A and B prepared above to 40-60 mesh, take 0.6ml each, mix them with equal volume of quartz sand, put them into a quartz reaction tube, and use 0.5ml in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com