Method for conversion of oil soluble quantum dots into water soluble quantum dots

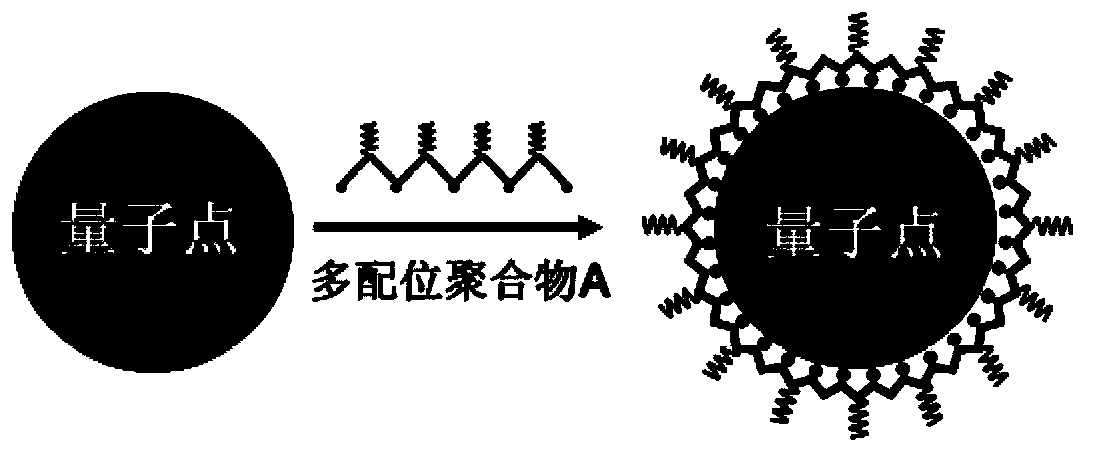

A quantum dot and oil-soluble technology, which is applied in the field of converting oil-soluble quantum dots into water-soluble quantum dots, can solve the problems of small volume and poor stability of quantum dots, achieve good reproducibility, simple method, and easy connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

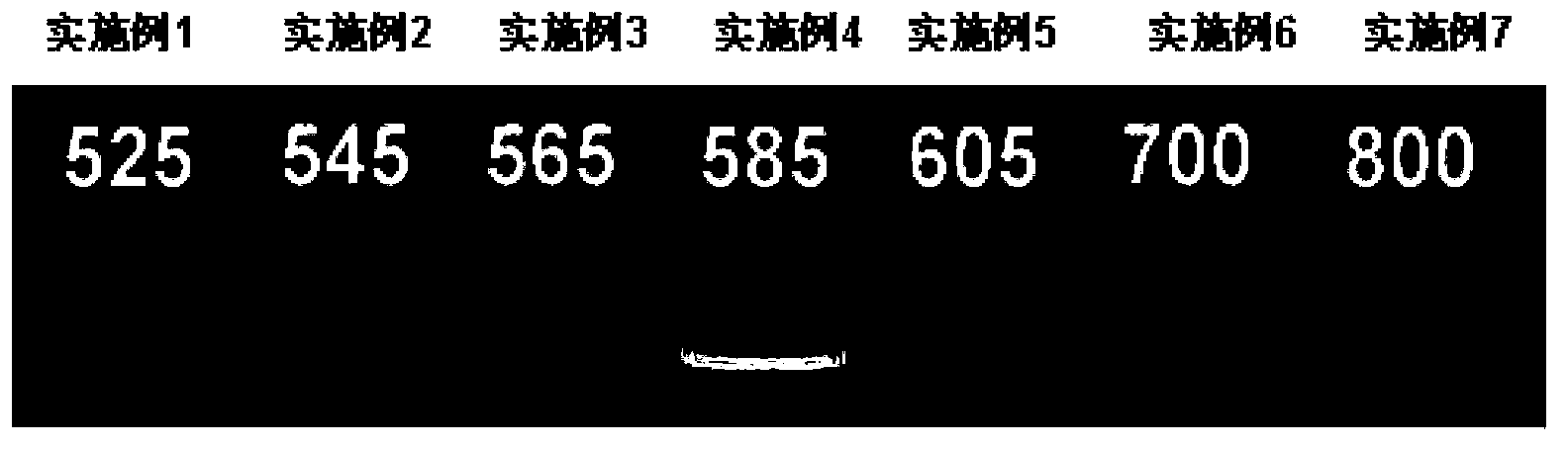

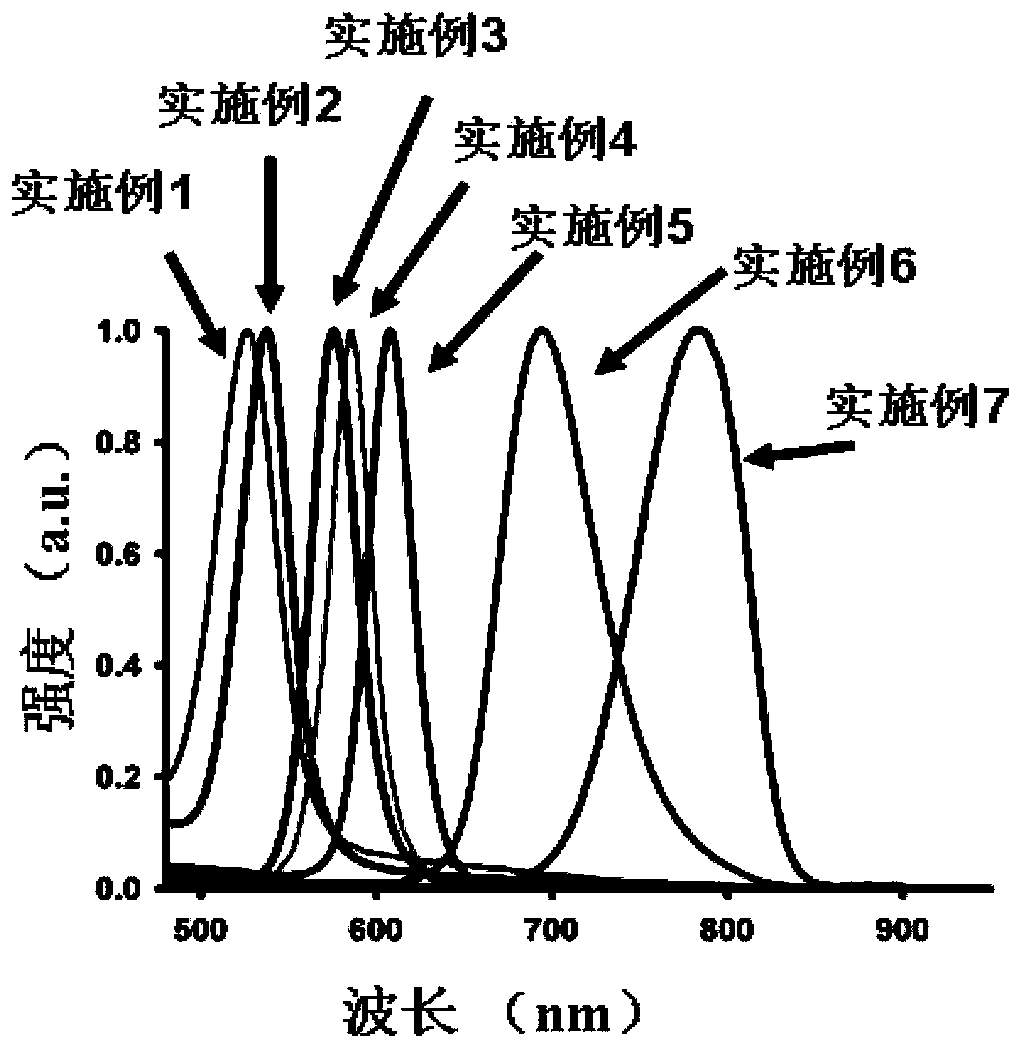

Embodiment 1

[0031] Step 1. Preparation of coordination polymer A: Weigh 1 g of polymaleic anhydride, 1 g of adenine or histamine, and 0.01 g of 4-dimethylaminopyridine, dissolve them in 20 ml of dimethyl sulfoxide, react for 8 hours, and set aside ;

[0032] Step 2. Preparation of chloroform solution B of oil-soluble quantum dots (CdSe / ZnS): This literature can be used (Li, J.J.; Wang, Y.A.; Guo, W.; Keay, J.C.; Mishima, T.D.; Johnson, M.B.; Peng , X.J.Am.Chem.Soc.2003,125,12567) to prepare oil-soluble quantum dots CdSe / ZnS, by controlling the reaction time to obtain quantum dots with an emission wavelength of 525nm, and then dissolve the quantum dots with an emission wavelength of 525nm in chloroform In, the prepared concentration is the chloroform solution of the oil-soluble quantum dot of 0.1mg / ml;

[0033]Step 3. Convert oil-soluble quantum dots into water-soluble quantum dots: slowly add 1ml of solution A to 1ml of solution B to form a transparent solution, then add 0.5ml of 1M sodi...

Embodiment 2

[0035] Step 1, with the step 1 of embodiment 1;

[0036] Step 2. Preparation of chloroform solution B of oil-soluble quantum dots (CdSe / ZnS): This literature can be used (Li, J.J.; Wang, Y.A.; Guo, W.; Keay, J.C.; Mishima, T.D.; Johnson, M.B.; Peng , X.J.Am.Chem.Soc.2003,125,12567) to prepare oil-soluble quantum dots CdSe / ZnS, by controlling the reaction time to obtain quantum dots with an emission wavelength of 545nm, and then dissolve the quantum dots with an emission wavelength of 545nm in chloroform In, the prepared concentration is the chloroform solution of the oil-soluble quantum dot of 0.1mg / ml;

[0037] Step 3, oil-soluble quantum dots are converted into water-soluble quantum dots: slowly add 1ml of solution A to 1ml of solution B to form a transparent solution, then add 0.5ml of 1M aqueous sodium hydroxide solution, centrifuge at 10000rpm for 10min and take the upper aqueous solution, and use A 50KDa ultrafiltration tube removes excess polymer, which is dissolved in...

Embodiment 3

[0039] Step 1, with the step 1 of embodiment 1;

[0040] Step 2. Preparation of chloroform solution B of oil-soluble quantum dots (CdSe / ZnS): This literature can be used (Li, J.J.; Wang, Y.A.; Guo, W.; Keay, J.C.; Mishima, T.D.; Johnson, M.B.; Peng , X.J.Am.Chem.Soc.2003,125,12567) to prepare oil-soluble quantum dots, by controlling the reaction time, to obtain quantum dots with an emission wavelength of 565nm, and then dissolve the quantum dots with an emission wavelength of 565nm in chloroform to prepare A chloroform solution of oil-soluble quantum dots with a concentration of 0.1 mg / ml was obtained;

[0041] Step 3, oil-soluble quantum dots are converted into water-soluble quantum dots: slowly add 1ml of solution A to 1ml of solution B to form a transparent solution, then add 0.5ml of 1M aqueous sodium hydroxide solution, centrifuge at 10000rpm for 10min and take the upper aqueous solution, and use A 50KDa ultrafiltration tube removes excess polymer, which is dissolved in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com