Processing technology using infrared ray radiant energy for curing cereal raw material and use method of cured cereal raw material in milk replacer and nursing material

A processing technology and radiant energy technology, applied in the field of feed processing, can solve the problems of inability to carry out large-scale production and low processing efficiency, and achieve the effects of improved feed intake, low processing energy consumption, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

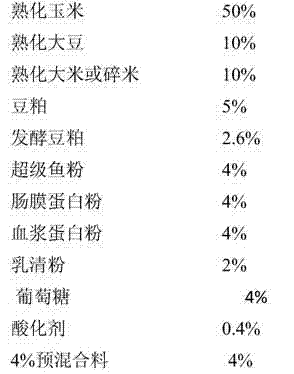

[0028] 1. Teach tank material formula:

[0029]

[0030] Above-mentioned raw material except ripe corn, ripe soybean, ripe rice or broken rice, other all can buy in raw material market.

[0031] 2. Processing method of cooked grain raw materials:

[0032] The mature corn is obtained through the following processing methods: ①The corn is passed through a three-cleaning sieve to remove impurities; ②The three-cleaned corn is lifted to the storage bin of the water-added oscillator; ③Adding water equivalent to 5% of the weight of the corn into the storage bin ; ④ Turn on the water-adding oscillator, vibrate at a frequency of 70 Hz for 30 seconds, so that the water is evenly distributed on the surface of the corn; ⑤ After the shaking, the corn is left to stand for 4 hours, so that the moisture content of the corn reaches 18%; ⑥ The corn begins to enter the infrared ray The total time for the radiant energy heating system to pass through the infrared radiant energy heating system...

Embodiment 2

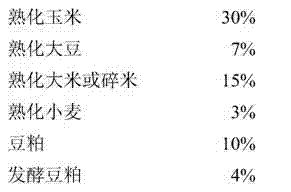

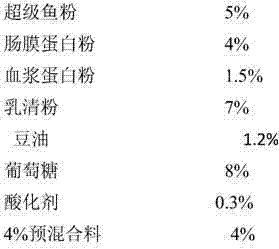

[0036] 1. Teach tank material formula:

[0037]

[0038]

[0039] The above-mentioned raw materials can be purchased in the raw material market except cooked corn, cooked soybeans, cooked rice or broken rice, and cooked wheat.

[0040] 2. Processing method of cooked grain raw materials:

[0041] The mature corn is obtained through the following processing methods: ①The corn is passed through a three-cleaning sieve to remove impurities; ②The three-cleaned corn is lifted to the storage bin of the water-added oscillator; ③Adding water equivalent to 6% of the weight of the corn into the storage bin ; ④ Turn on the water-adding oscillator and vibrate at a frequency of 75 Hz for 30 seconds to evenly distribute the water on the surface of the corn; Infrared radiant energy heating system, the total time of passing through the infrared radiant energy heating system is 50s. The system uses electricity for infrared heating, which instantly makes the temperature in the system reach...

Embodiment 3

[0046] 1. Teach tank material formula:

[0047]

[0048]

[0049] The above-mentioned raw materials can be purchased in the raw material market except cooked corn, cooked soybeans, cooked rice or broken rice, and cooked wheat.

[0050] 2. Processing method of cooked grain raw materials:

[0051] The mature corn is obtained through the following processing methods: ①The corn is passed through a three-cleaning sieve to remove impurities; ②The three-cleaned corn is lifted to the storage bin of the water-added oscillator; ③Adding water equivalent to 8% of the weight of the corn into the storage bin ; ④ Turn on the water-adding oscillator and vibrate at a frequency of 80 Hz for 30 seconds, so that the water is evenly distributed on the surface of the corn; The total time for the radiant energy heating system to pass through the infrared radiant energy heating system is 60s. The system uses biogas for infrared heating, which instantly makes the temperature inside the system r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com