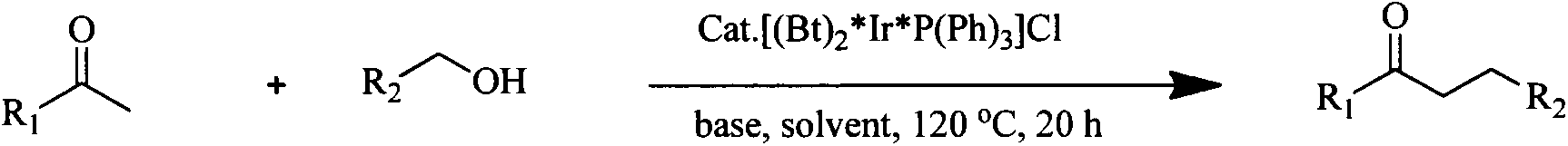

Novel method for synthesizing functionalized ketone through reaction of aromatic ketone and primary alcohol

An aromatic ketone, functionalization technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as harsh reaction conditions and toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment one: a kind of new method of synthesizing functionalized ketone by aromatic ketone and primary alcohol reaction, comprises the following process steps:

[0022] Under nitrogen protection, in 50mL Schlenk tube, add acetophenone (120mg, 1mmol), benzyl alcohol (130mg, 1.2mmol), [(Bt) 2 *Ir*P(Ph) 3 ]Cl (10mg, 0.01mmol, 1.0mol%), cesium carbonate (326mg, 1.0mmol), and 2.0mL tert-amyl alcohol were added; the reaction solution was reacted at 120°C for 20h, and the resulting solution was separated with a 200-300 mesh silica gel column (washing Deliquification is 1: 10 ethyl acetate / petroleum ether), after removing the solvent, the corresponding product is obtained, and the structural formula is: White crystals, melting point: 72-74°C, yield: 92%.

Embodiment 2

[0023] Embodiment two: a kind of novel method of synthesizing functionalized ketone by aromatic ketone and primary alcohol reaction, comprises the following processing steps: under nitrogen protection, in 50mL Schlenk tube, add acetophenone (120mg, 1mmol), 3-hydroxymethyl Pyridine (131 mg, 1.2 mmol), [(Bt) 2 *Ir*P(Ph) 3 ]Cl (10mg, 0.01mmol, 1.0mol%), cesium carbonate (326mg, 1.0mmol), and 2.0mL tert-amyl alcohol were added; the reaction solution was reacted at 120°C for 20h, and the resulting solution was separated with a 200-300 mesh silica gel column (washing Deliquification is 1: 10 ethyl acetate / petroleum ether), after removing the solvent, the corresponding product is obtained, and the structural formula is: White crystals, melting point: 84-86°C, yield: 86%.

Embodiment 3

[0024] Embodiment three: a kind of new method of synthesizing functionalized ketone by aromatic ketone and primary alcohol reaction, comprises the following processing steps: under nitrogen protection, in 50mL Schlenk tube, add acetophenone (120mg, 1mmol), 4-hydroxymethyl Pyridine (131 mg, 1.2 mmol), [(Bt) 2 *Ir*P(Ph) 3 ]Cl (10mg, 0.01mmol, 1.0mol%), cesium carbonate (326mg, 1.0mmol), and 2.0mL tert-amyl alcohol were added; the reaction solution was reacted at 120°C for 20h, and the resulting solution was separated with a 200-300 mesh silica gel column (washing Deliquification is 1: 10 ethyl acetate / petroleum ether), after removing the solvent, the corresponding product is obtained, and the structural formula is: White crystals, melting point: 64-67°C, yield: 83%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com