Rigidity adjusting device for spiral springs and tuned mass damping device

A technology of adjusting device and coil spring, applied in the direction of non-rotational vibration suppression, etc., can solve the problems of weakening the control effect of TMD vibration reduction, reducing the applicability of TMD device, and difficult to adjust the stiffness of spring unit, so as to achieve convenient and effective adjustment of stiffness and quality, Practical value of large projects, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

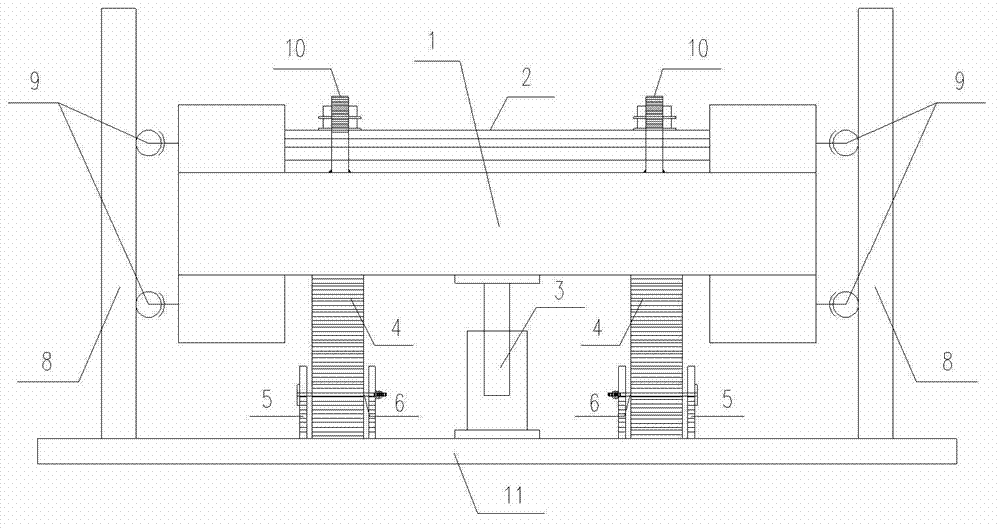

[0035] Such as figure 1 As shown, the adjustable vertical tuning mass damping device proposed by the present invention mainly includes a fixed mass 1, an adjustable mass 2, a viscous damper 3 and a coil spring 4, wherein the adjustable mass 2 is welded to the fixed mass The fixed screw rod 10 on the block 1 is bolted to the fixed mass block 1, and the coil spring 4 extends into the fixed end cylinder 5 and is fixed to the connecting part 11 (it can be a beam-type, plate-type or truss-type connecting part), and the other end of the coil spring 4 It is fixed at the bottom of the mass block, and the fixed end cylinder 5 is provided with a clamping hole 7 (the structure of the fixed end cylinder and the clamping plate shows the views Figure 5 , Figure 6 ), the clamp plate 6 passes through the spring 4 through the clamp hole 7 on the fixed end cylinder 5, and the guide wheel 9 is welded to the mass block 1 and pre-pressed to guide the side plate 8. When the vibration occurs, th...

Embodiment 2

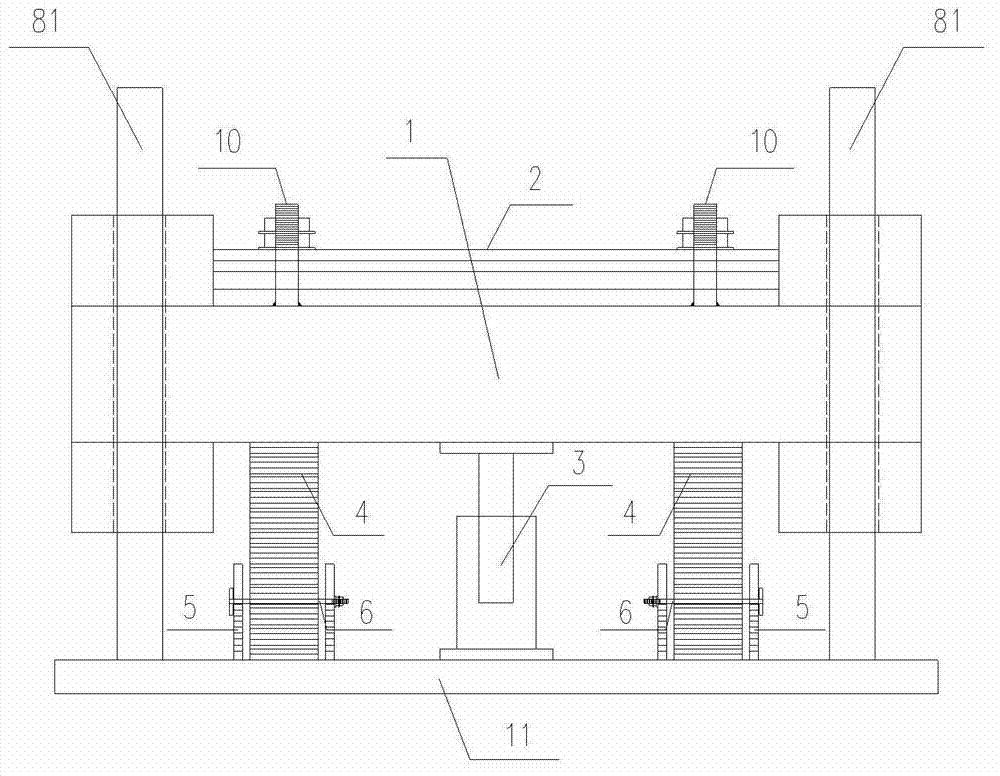

[0041] Such as figure 2 As shown, the difference from the first embodiment is that the guide device in the second embodiment adopts a guide rod. What is different from the traditional guide rod is that the present invention proposes to add isolation on the surface of the guide rod 81 and in the preset guide hole of the mass block. Materials, specifically, elastic materials with low coefficient of friction or lubricating materials can be used, such as: liquid lubricating oil, soap-based and non-soap-based grease, graphite, polytetrafluoroethylene, etc.; sleeves can also be placed on the guide rod and guide Between the holes, the section of the sleeve 18 is as Figure 7 As shown, the sleeve is provided with a chute, and the guide rod contacts the guide hole through the ball 19 in the sleeve chute. In actual work, the guide rod vibrates up and down along the guide hole, which changes the sliding friction between the traditional guide rod and the guide hole. for rolling friction...

Embodiment 3

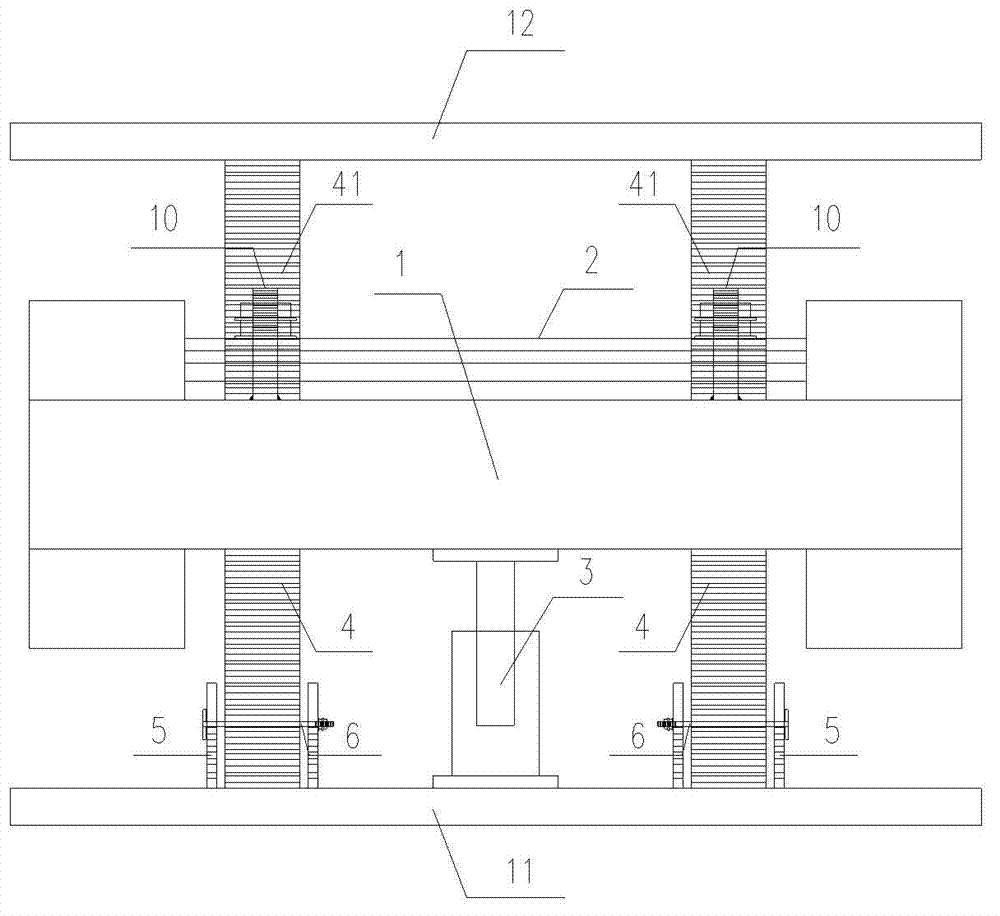

[0043] Such as image 3 As shown, different from the specific embodiment 1, the adjustable vertical tuning mass damping device proposed by the present invention adopts 8 sets of double-layer symmetrical springs, and the mass block 1 and the mass block 2 are placed between the spring 4 and the spring 41. , the setting of double-layer springs can effectively avoid the shaking and overturning of the mass block during the vibration process, and can realize self-guiding without additional guiding devices, which ensures the vibration reduction control effect of the device and simplifies the structure at the same time. When the device is connected to the main structure, a support pier needs to be set vertically at the structural layout position according to the building space and the size of the device, and the vertical stiffness of the support pier must meet the requirement that the deformation of the adjustable vertical tuning mass damping device is not greater than 2mm during opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com