A processing method of thin-walled membrane disc based on soft tire lamination and clamping

A processing method and technology of thin-walled disks, applied in metal processing equipment, metal processing machine parts, clamping, etc., can solve problems such as stress recovery deformation, clamping stress deformation, and affecting the processing accuracy of thin-walled disk parts, and achieve Reduce stress and deformation, improve the degree of bonding, and quickly and efficiently shape the effect of replicating manufacturing functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

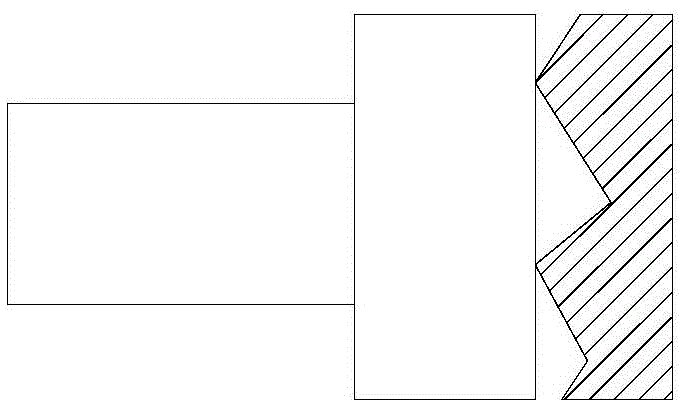

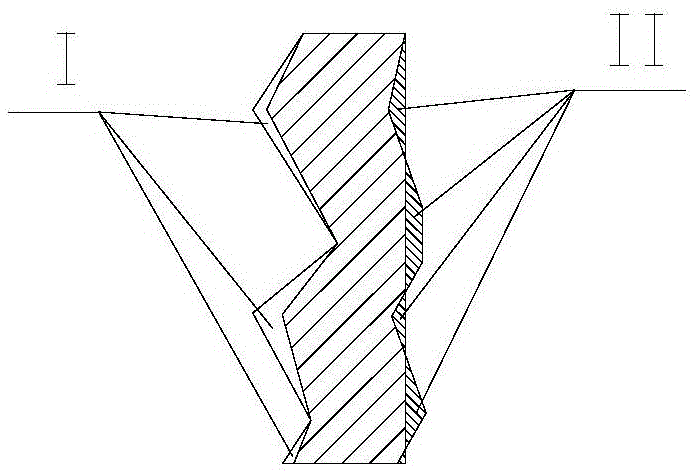

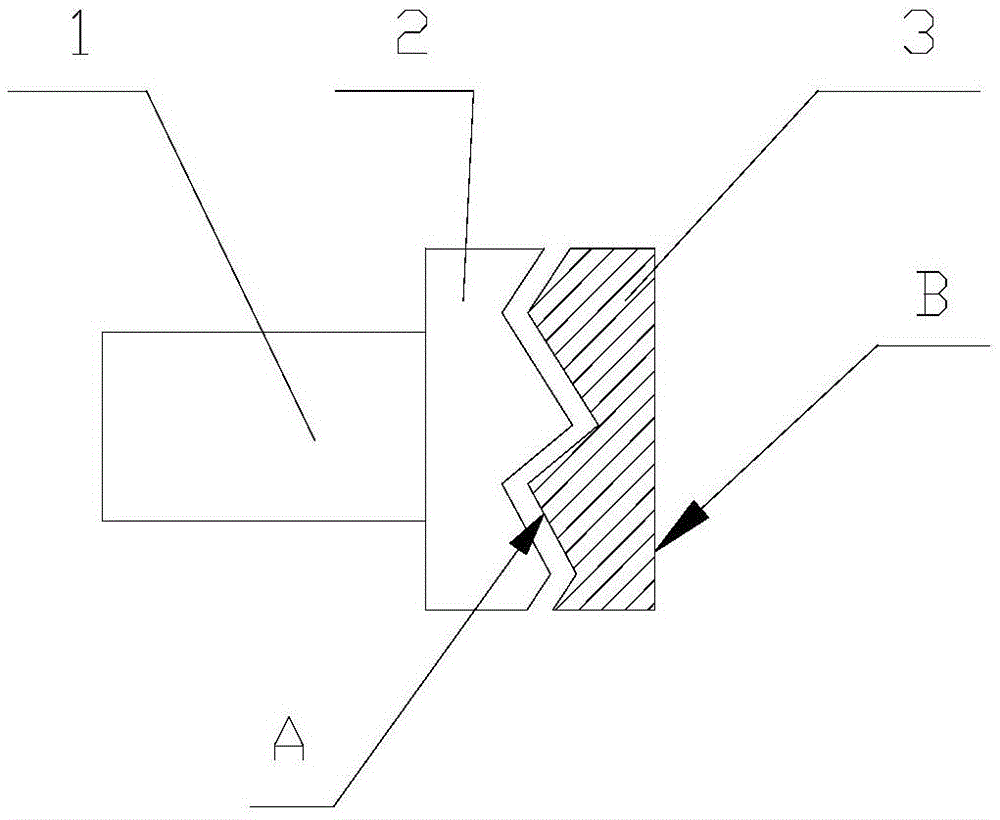

[0054]A turboshaft engine power shaft diaphragm, its outer diameter is Φ112, the thickness of the diaphragm is 0.6mm, and the thinnest part is 0.35mm, the processed diaphragm is required to meet the following requirements: the profile of the diaphragm is required to be -0.004mm ~+0.020mm, surface roughness requirement Ra0.12, the specific processing steps are:

[0055] 1. Rough processing:

[0056] Use 3D drawing software to carry out digital 3D configuration of the thin-walled disk parts to be processed, and input them into the CNC machine tool;

[0057] Adjust the CNC machine tool, the spindle rotation accuracy of the CNC machine tool is 0.01mm; clamp the surface topography measuring device and the precision machining device on the adjusted CNC machine tool, adjust the positions of the surface topography measurement device and the precision machining device so that both The trajectory of the motion is the same, and the projection of the trajectory on the end face of the thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com