Method for Purifying Cationic Etherifying Agent with Phosphate Ester Extractant

A technology of cationic etherification agent and phosphate esters, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of restricting sustainable development, difficult and difficult treatment of organic wastewater, etc., and achieve good use effect , less investment in equipment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

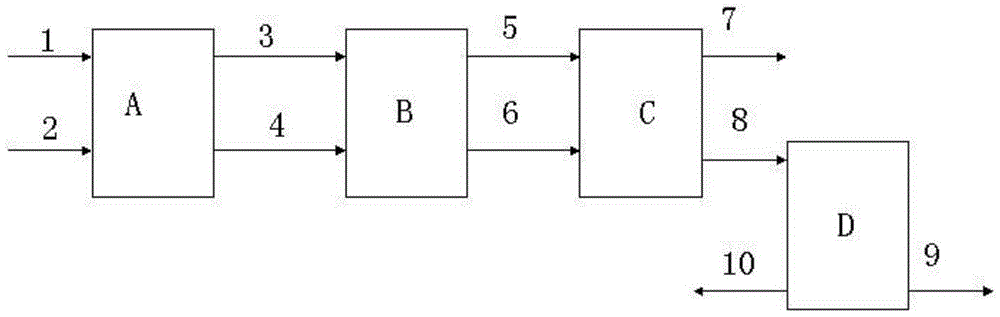

Method used

Image

Examples

Embodiment 1

[0020] Take trioctyl phosphate as an example to purify cationic etherification agent:

[0021] 1. Extraction

[0022] The content of epichlorohydrin in the crude product cationic etherification agent 3-chloro-2-hydroxypropyltrimethylammonium chloride is 1622mg kg -1 , the content of 1,3-dichloro-2-propanol is 18472mg·kg -1 . Extractant with V 粗产品 :V 萃取剂 =1:0.7 ratio, after one continuous extraction, the content of epichlorohydrin in the cationic etherification agent is 15mg·kg -1 , the content of 1,3-dichloro-2-propanol is 32mg·kg -1 ; After 2 consecutive extractions, the content of epichlorohydrin in the cationic etherification agent is 6 mg kg -1 , the content of 1,3-dichloro-2-propanol is 12mg·kg -1 .

[0023] 2. Regeneration

[0024] The regeneration conditions of trioctyl phosphate: the concentration is 7% NaOH aqueous solution, the temperature is 120 ° C, the regeneration time is 3 hours, after recycling 6 times, epichlorohydrin and 1,3-dichloro-2- Propanol con...

Embodiment 2

[0026] Take triisobutyl phosphate as the extraction agent to purify cationic etherification agent as an example:

[0027] 1. Extraction

[0028] The content of epichlorohydrin in the crude product cationic etherification agent 3-chloro-2-hydroxypropyltrimethylammonium chloride is 1622mg kg -1 , the content of 1,3-dichloro-2-propanol is 18472mg·kg -1 . Extractant with V 粗产品 :V 萃取剂 =1:0.8 ratio, after one continuous extraction, the content of epichlorohydrin in cationic etherifying agent is 36mg·kg -1 , the content of 1,3-dichloro-2-propanol is 70mg·kg -1 ; After 2 consecutive extractions, the content of epichlorohydrin in the cationic etherifying agent is 10 mg kg -1 , the content of 1,3-dichloro-2-propanol is 15mg·kg -1 ; After 4 consecutive extractions, epichlorohydrin and 1,3-dichloro-2-propanol were not detected by the cationic etherifying agent.

[0029] 2. Regeneration

[0030] The regeneration condition of triisobutyl phosphate: the concentration is 6%Na 2 CO ...

Embodiment 3

[0032] Take tributyl phosphate as the extraction agent to purify cationic etherification agent as an example:

[0033] 1. Extraction

[0034] The ECH content in the crude product cationic etherification agent 3-chloro-2-hydroxypropyltrimethylammonium chloride is 1885mg kg -1 , DCP content is 23265mg·kg -1 . Extractant with V 粗产品 :V 萃取剂 =1:1.1 ratio, after one continuous extraction, the content of epichlorohydrin in the cationic etherification agent is 46mg·kg -1 , the content of 1,3-dichloro-2-propanol is 82mg·kg -1 ; After 2 consecutive extractions, the content of epichlorohydrin in the cationic etherifying agent is 18 mg kg -1 , the content of 1,3-dichloro-2-propanol is 25mg·kg -1 .

[0035] 2. Regeneration

[0036] The regeneration conditions of tributyl phosphate: the concentration is 5% tetrabutylammonium hydroxide aqueous solution, the temperature is 120 ℃, the regeneration time is 6 hours, after recycling 6 times, epichlorohydrin and 1,3- The content of dichloro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com