Agar gel microspheres and preparation method thereof

An agar gel and microsphere technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of poor mechanical strength of agar gel bare spheres, high cost of biochemical separation and purification media, and achieve difficult to buy, strong rigidity, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: secondary cross-linking method and steps

[0048] Take 10g of cross-linked 6B agar gel microspheres as an example:

[0049] Take 6% agar gel microspheres, wash them with water and filter dry, then weigh 10 g of bare agar spheres in a three-necked flask, add water with the same volume as the bare agar spheres, and pour it into the flask, add 2ml of cross-linking agent1,4 -Butanediol diglycidyl ether, mix well. Stir at 60-100rpm for 2-3h, then stand overnight at 20°C. [This process is a process in which the long cross-linking agent diffuses into the interior of the agar microspheres, so that the cross-linking agent can evenly diffuse into the interior of the gel microspheres, making the cross-linking process easier]

[0050] Stir mechanically for 1 hour at room temperature at 20°C; add 0.6ml of NaOH solution with a mass percent concentration of 40%-50% dropwise to the system within 20 minutes and add 0.15g of NaBH 4 ;React for 4 hours, mechanically stir t...

Embodiment 2

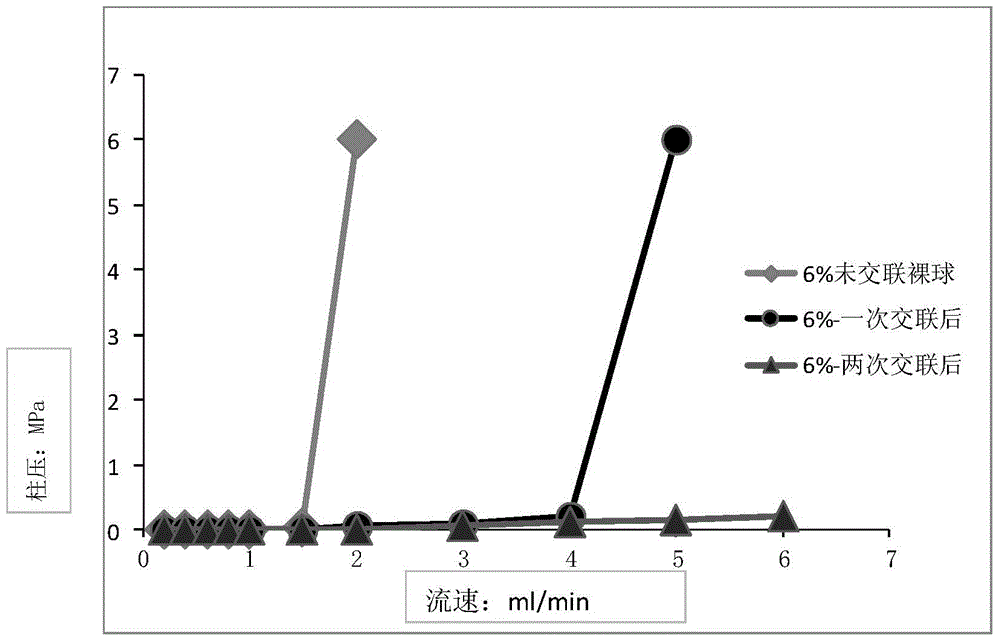

[0055] Embodiment 2: flow rate pressure after agar gel microsphere packing column

[0056] The uncrosslinked, primary crosslinked and secondary crosslinked agar gel microsphere packing column (the inner diameter of the column is 1cm, and the column height is 28cm) is connected to the AKTA chromatographic system, and the flow rate increases to each gel. After the highest limit of the gel column, measure the relationship between the flow rate and pressure curve, figure 1 It is the pressure-velocity curve graph after uncrosslinked, primary crosslinked and secondary crosslinked, the square is the bare ball without crosslinking, the circle is after the primary crosslinking, and the triangle is after the secondary crosslinking. The results can be seen To: Compared with the effect after the first cross-linking, the microspheres after the second cross-linking have higher mechanical strength, are more able to withstand pressure and high flow rate, and are more suitable for amplificatio...

Embodiment 3

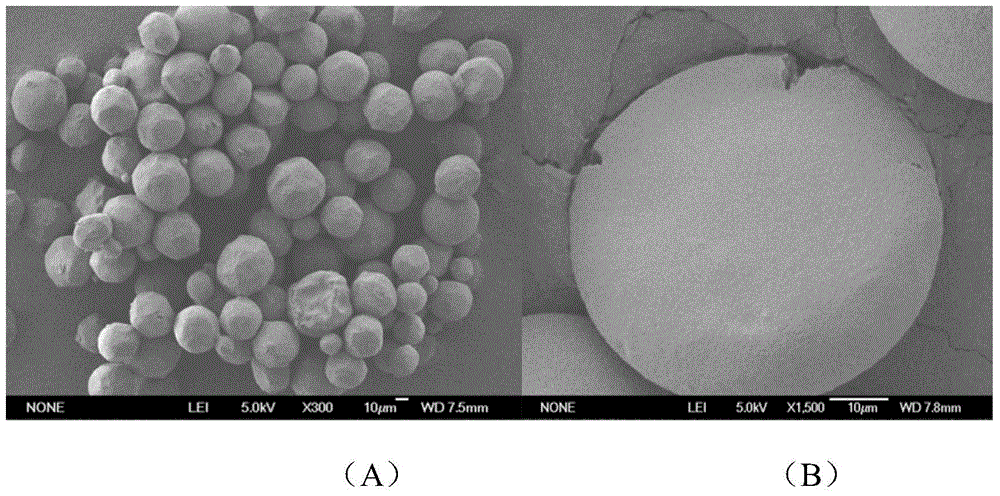

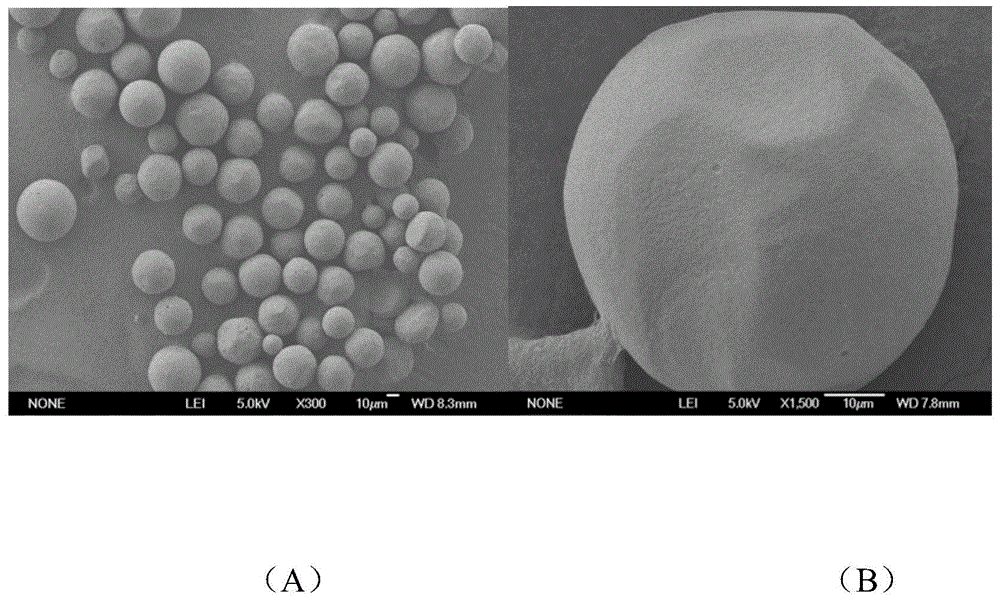

[0057] Example 3: SEM analysis of agar microspheres after secondary crosslinking

[0058] Depend on Figure 2-4 It can be seen that most of the uncrosslinked bare balls have shriveled after drying and cannot maintain their complete spherical properties. However, most of the uncrosslinked bare balls can maintain their complete spherical shape after drying, but their surface structure has changed. There were different degrees of depressions, but the microspheres after the secondary crosslinking could still maintain their complete spherical properties after drying, and there was basically no damage under the electron microscope observation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com