Method for controlling nanocrystalline graphene size in carbon film through electron cyclotron resonance (ECR) electron irradiation density

A technology of electron irradiation and density control, applied in sputtering plating, ion implantation plating, vacuum evaporation plating, etc., can solve the problems of inconvenient precise control of nanocrystalline graphene size, high requirements for substrate materials and processing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

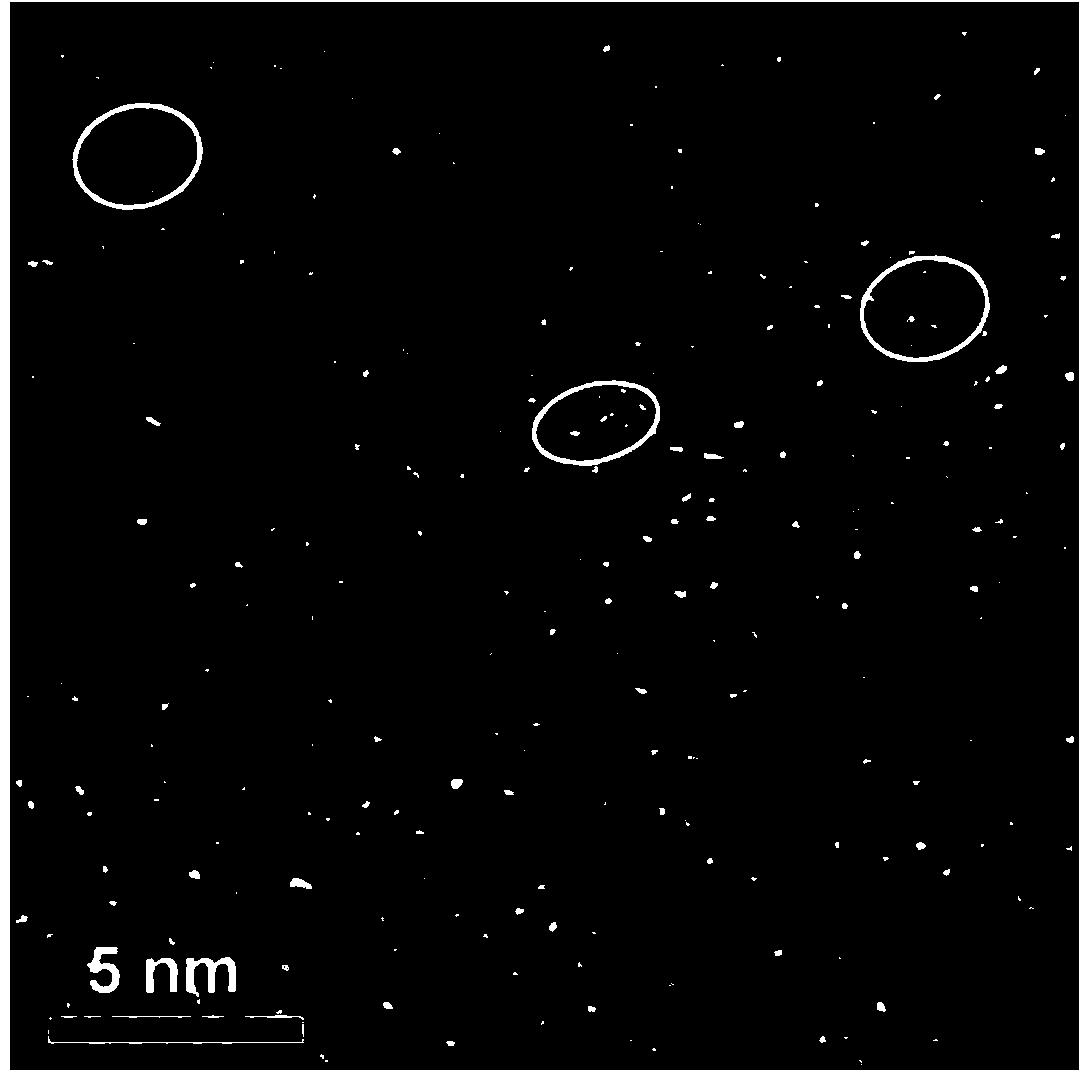

[0026] 1) Clean the p-type Si (100) substrate ultrasonically in a mixed solvent of acetone and ethanol, and then dry it naturally; fix the substrate on an area of 12.56cm 2 on the substrate rack and put it into the vacuum chamber; after the two-stage vacuuming of the mechanical pump and the molecular pump, when the vacuum degree of the system reaches 2×10 -4 Pa, through the argon, and stabilize the pressure at 4 × 10 -2 Pa: Apply a magnetic coil with a current of 420A to generate a magnetic field, introduce microwaves with a microwave power of 160W and couple with the magnetic field to generate plasma, and stabilize for 20 minutes.

[0027] Before coating, use argon ions to clean the surface of the substrate; after that, turn on the target sputtering bias -300V, and the argon ions in the plasma accelerate the bombardment of the carbon target, so that the carbon atoms in the carbon target are released into the plasma space, Deposit and form a carbon film on the surface of th...

Embodiment 2

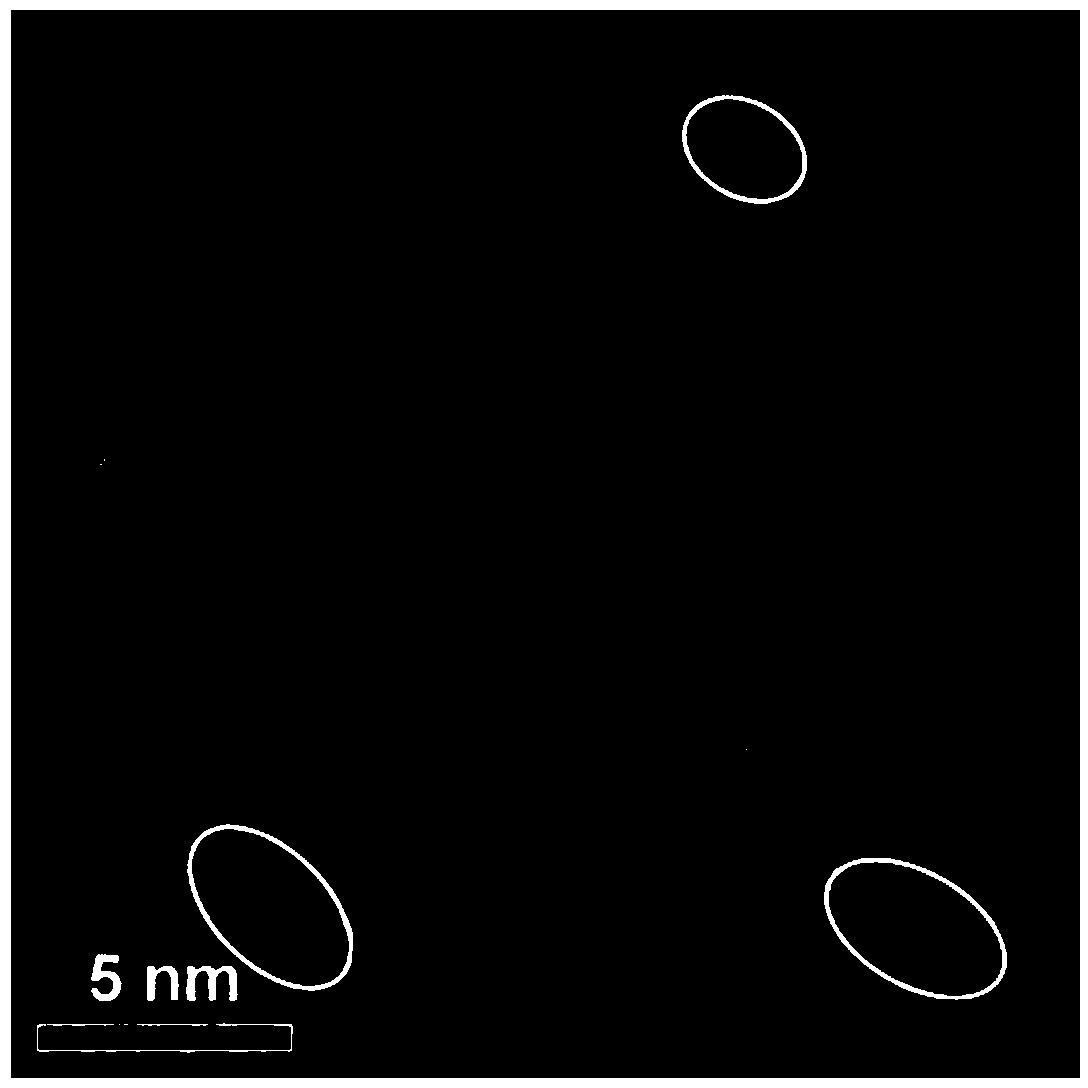

[0031] 1) Clean the p-type Si (100) substrate ultrasonically in a mixed solvent of acetone and ethanol, and then dry it naturally; fix the substrate on an area of 12.56cm 2 on the substrate rack and put it into the vacuum chamber; after the two-stage vacuuming of the mechanical pump and the molecular pump, when the vacuum degree of the system reaches 4×10 -4 Pa, through the argon, and make the pressure stable at 2×10 -2 Pa: Apply a current of 350A to the magnetic coil to generate a magnetic field, introduce microwaves with a microwave power of 200W to couple with the magnetic field to generate plasma, and stabilize for 20 minutes.

[0032] Before coating, use argon ions to clean the surface of the substrate; after that, turn on the target sputtering bias -250V, and the argon ions in the plasma accelerate the bombardment of the carbon target, so that the carbon atoms in the carbon target are released into the plasma space, Deposit and form a carbon film on the surface of the...

Embodiment 3

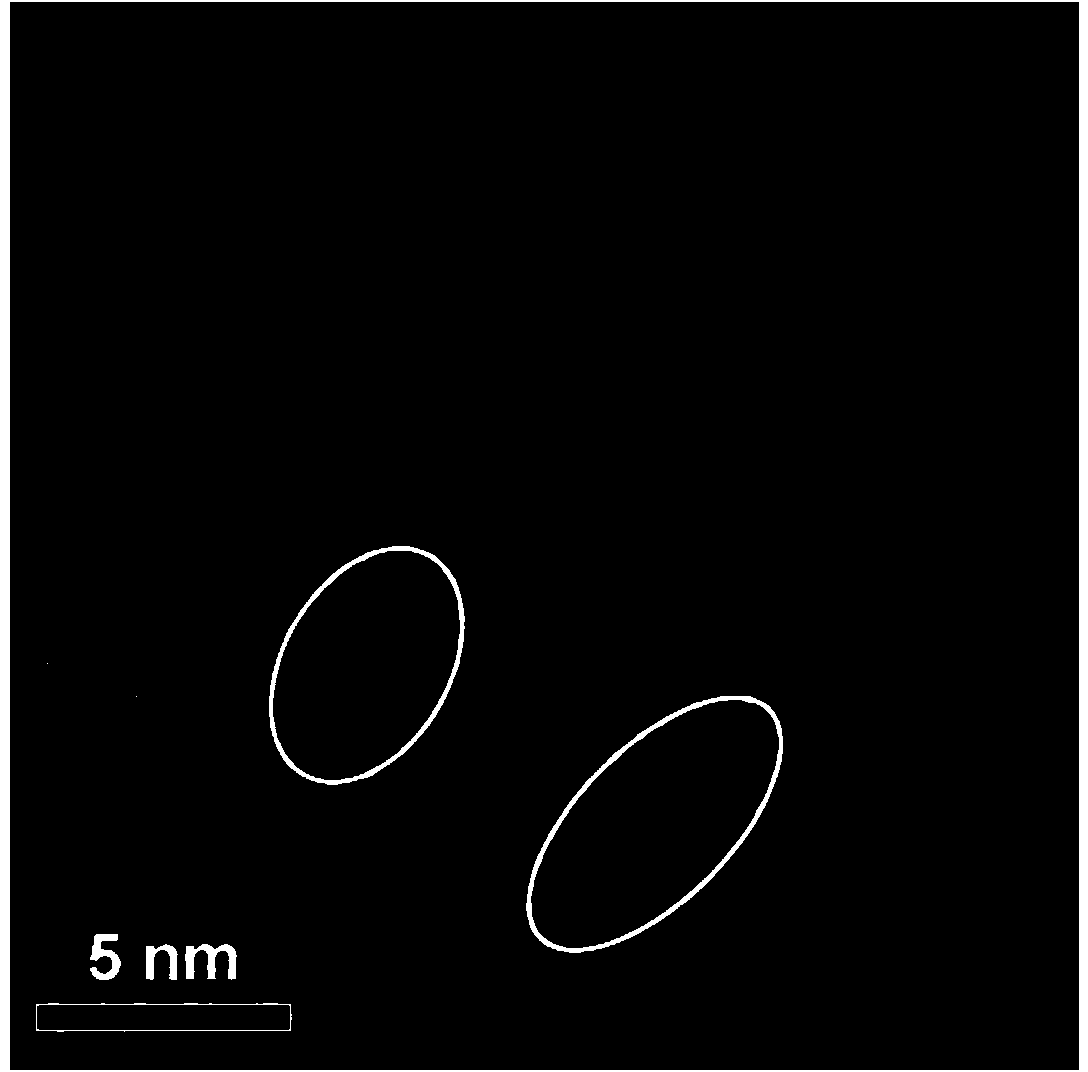

[0036] 1) Clean the p-type Si (100) substrate ultrasonically in a mixed solvent of acetone and ethanol, and then dry it naturally; fix the substrate on an area of 12.56cm 2 on the substrate rack and put it into the vacuum chamber; after the two-stage vacuuming of the mechanical pump and the molecular pump, when the vacuum degree of the system reaches 3×10 -4 Pa, through the argon, and make the pressure stable at 6×10 -2 Pa: Apply a current of 400A to the magnetic coil to generate a magnetic field, and introduce microwaves with a microwave power of 300W to couple with the magnetic field to generate plasma, which is stable for 20 minutes.

[0037] Before coating, use argon ions to clean the surface of the substrate; after that, turn on the target sputtering bias -280V, and the argon ions in the plasma accelerate the bombardment of the carbon target, so that the carbon atoms in the carbon target are released into the plasma space, Deposit and form a carbon film on the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com