Polyimide coated optical fiber and machining process thereof

A polyimide coating, polyimide technology, applied in the direction of cladding fiber, optical waveguide light guide, etc., can solve the problems of fiber failure, accelerated fiber fatigue process, accelerated coating polymer chain, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

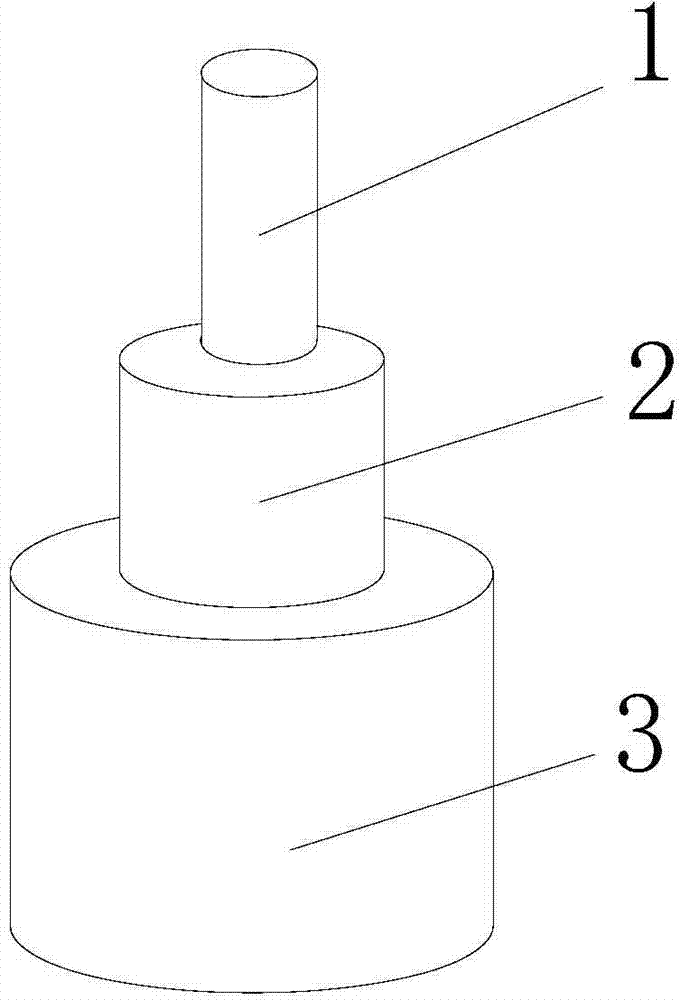

[0047] refer to figure 1 , the invention comprises that the diameter of the quartz core layer of the bare optical fiber is 9 μm, the diameter of the quartz cladding layer is 125 μm, and the diameter of the polyimide coating layer is 155 μm, which is a high-temperature-resistant optical fiber for communication.

[0048] Production steps: Melt an optical fiber preform rod with a diameter of 60mm in a high-temperature graphite induction furnace at 1950°C, and draw it into an optical fiber by drawing and drawing. The spinning speed is 8m / min, and the cladding diameter of the bare fiber is 125μm. The bare optical fiber went through two on-line coating-curing cycles. After the initial coating, the outer diameter of the polyimide coating was 137 μm, and the thickness on one side was 6 μm. Wherein each online coating and curing process coats a single side with a thickness of 3 μm. Wind the preliminarily coated optical fiber on the reel, and wait for the off-line process. The proces...

Embodiment 2

[0059] The difference between Example 2 and Example 1 is that the core diameter of the bare fiber is 400 μm, the cladding diameter is 440 μm, and the diameter of the polyimide coating layer is 470 μm, which is a high-temperature-resistant large-core energy transmission fiber .

[0060] Production steps: melt the polarization-maintaining preform rod with a diameter of 40mm in a high-temperature graphite induction furnace at a temperature of 2050°C, and draw it into an optical fiber by drawing and drawing. The spinning speed is 4 m / min, and the cladding diameter of the optical fiber is 440 μm. After two online coating and curing cycles, the thickness of one side of each coating is 3 μm. After the initial coating, the outer diameter of the polyimide coating is 452 μm. . The online coating process parameters are shown in the following table 2-1:

[0061] table 2-1

[0062] parameter name

value

Drawing speed, m / min

4

Viscosity of polyimide soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com