Femtosecond laser device based on single cladding neodymium optical fibers and ring cavity and manufacturing method

A femtosecond laser and single-clad technology, which is applied in lasers, laser components, phonon exciters, etc., can solve the problems of low light-to-light conversion efficiency, large fusion loss, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

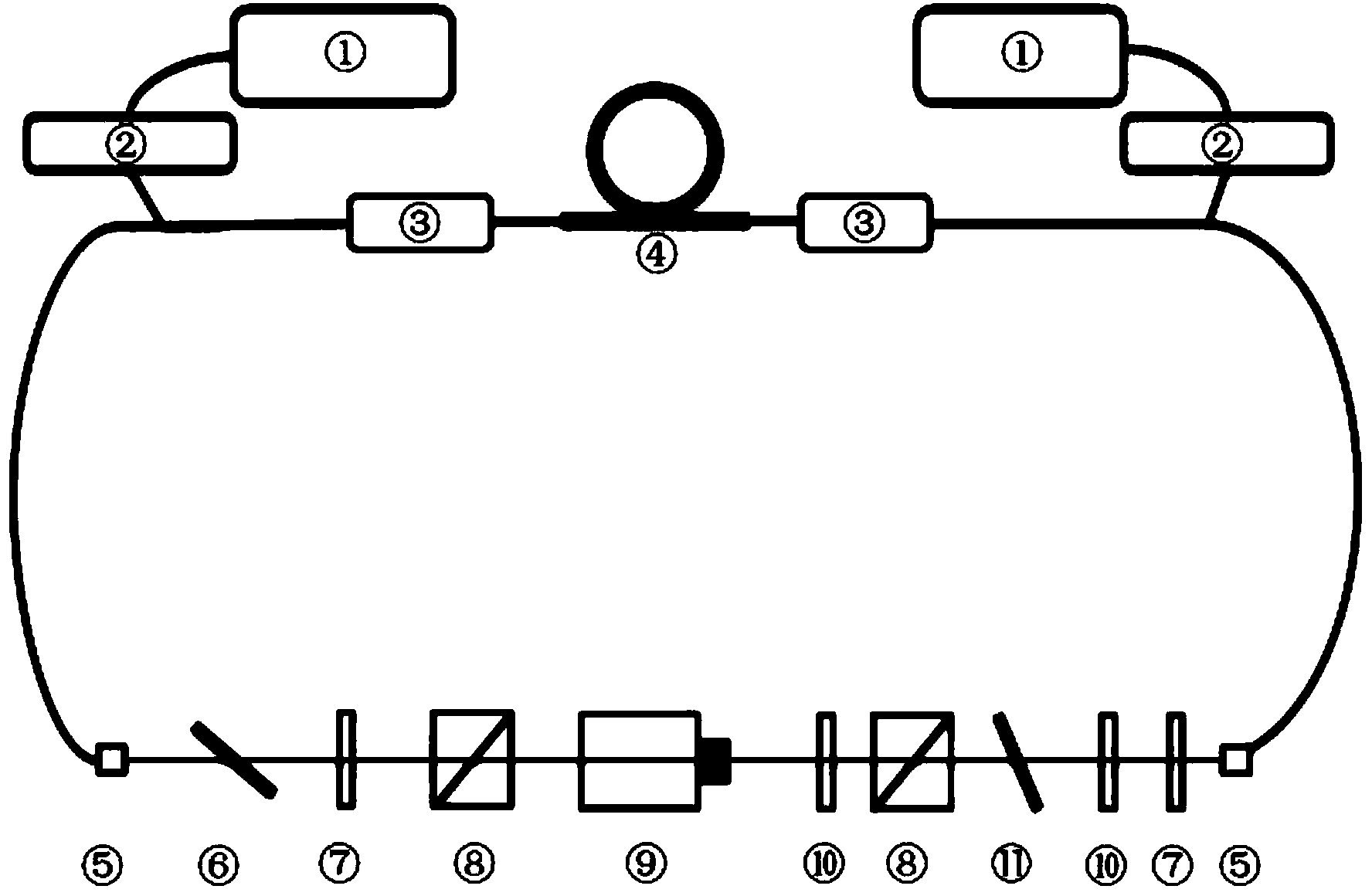

[0034] figure 1 It is a structural schematic diagram of a femtosecond laser based on a single-clad neodymium fiber and a ring cavity of a preferred embodiment of the present invention; in this embodiment, the femtosecond laser based on a single-clad neodymium-doped fiber and a ring cavity Laser, the femtosecond laser includes a cavity part and a spatial optical path part; the cavity part includes an 808nm single-mode semiconductor optical pump 1, an 808nm fiber-optic single-mode isolator 2, an 808 / 920nm wavelength division multiplexer 3, Single-clad neodymium-doped gain fiber 4, 920nm fiber collimator 5; the spatial optical path part includes a low-pass dichroic mirror 6, a 920nm1 / 4 wave plate 7, a 920nm polarization beam splitting prism 8, a 920nm Faraday rotator 9, 920nm 1 / 2 wave plate 10, birefringence filter 11; the 808nm single-mode semiconductor optical pump 1, the 808nm fiber-optic single-mode isolator 2, and the 808 / 920nm wavelength division multiplexer 3 are welded to...

Embodiment 2

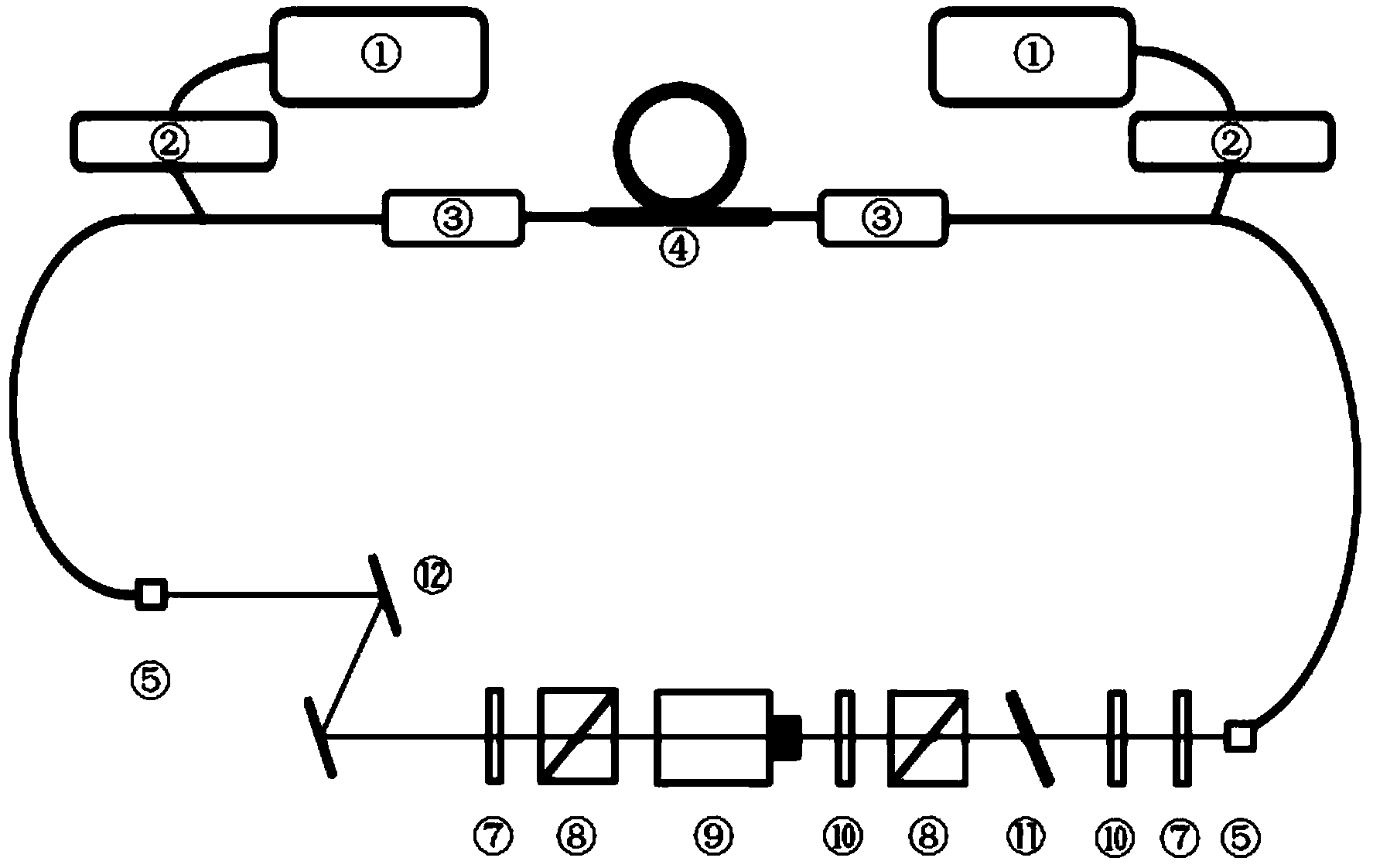

[0045] figure 2 It is a structural schematic diagram of a femtosecond laser based on a single-clad neodymium fiber and a ring cavity according to another preferred embodiment of the present invention; compared with Embodiment 1, this embodiment adds an optical device dispersion compensation grating pair 12, Located between the 920nm fiber collimator (5) of the first cavity and the 920nm1 / 4 wave plate (7) of the spatial optical path part, the low-pass dichroic mirror (6) is connected from the spatial optical path part remove. The dispersion compensation grating pair 12 is a reflective grating or a transmissive grating. The cavity part of this embodiment is the same as that of this embodiment, and the manufacturing method of this embodiment is the same as that of Embodiment 1, which will not be repeated here.

Embodiment 3

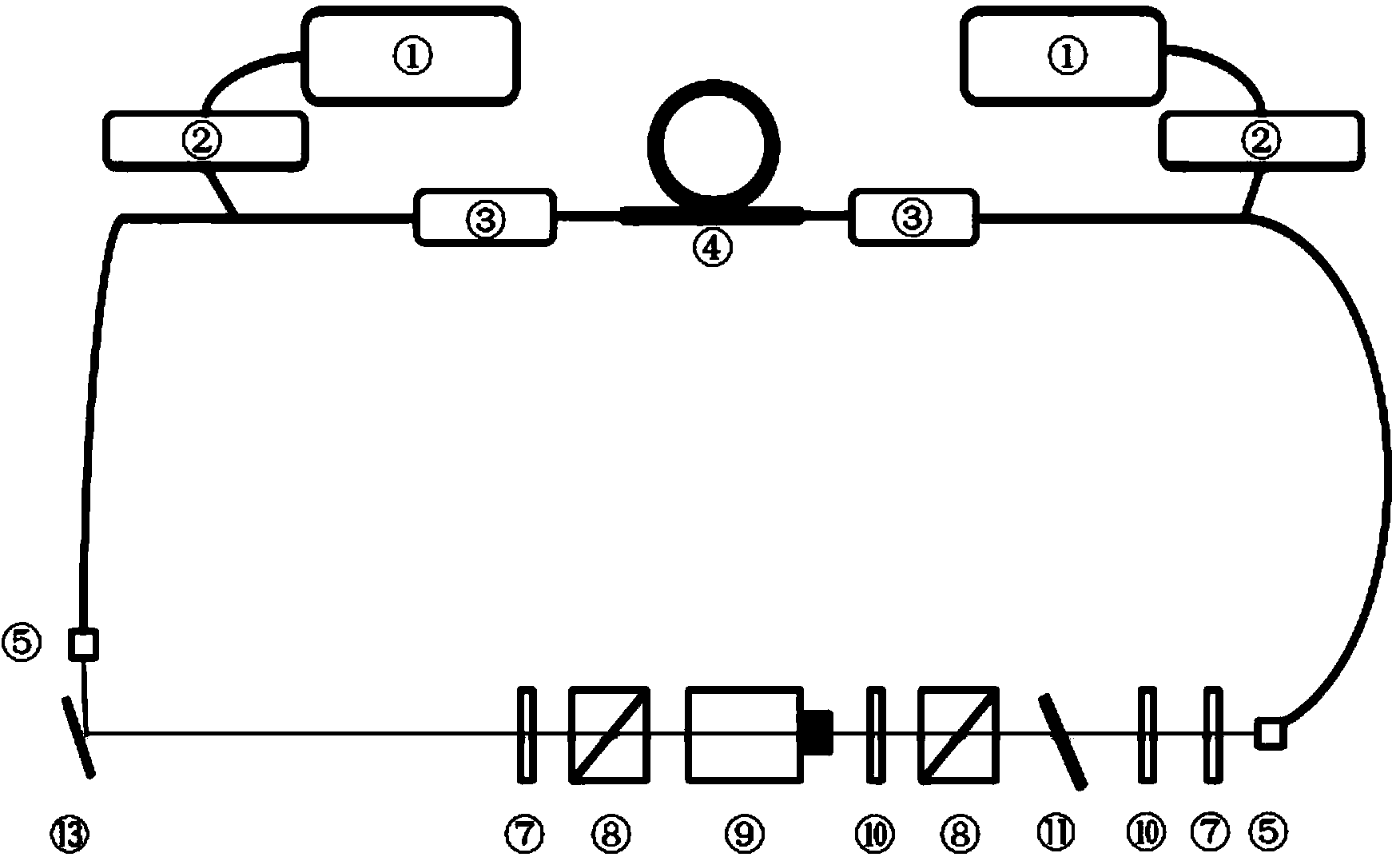

[0047] image 3 It is a structural schematic diagram of a femtosecond laser based on a single-clad neodymium fiber and a ring cavity according to another preferred embodiment of the present invention; compared with Embodiment 1, this embodiment adds an optical device filter grating 13, which is located at the Between the 920nm fiber collimator (5) of cavity 1 and the 920nm1 / 4 wave plate (7) of the spatial optical path part, the low-pass dichroic mirror (6) is removed from the spatial optical path part. The filter grating 13 is a reflective grating or a transmissive grating. The cavity part of this embodiment is the same as that of this embodiment, and the manufacturing method of this embodiment is the same as that of Embodiment 1, which will not be repeated here.

[0048] A femtosecond laser based on a single-clad neodymium fiber and a ring cavity of the present invention uses 808nm single-mode semiconductor optical pumping as an excitation light source to ensure sufficient h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com