Converter valve assembly and valve tower using the converter valve assembly

A converter valve and component technology, applied in the direction of semiconductor/solid-state device parts, electrical components, electro-solid devices, etc., can solve the inconvenience of valve tower installation and maintenance, valve tower installation and maintenance operations, various units and water cooling systems. Discrete layout structure, etc., to achieve the effect of convenient and quick installation and maintenance, expansion of installation and maintenance space, and convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

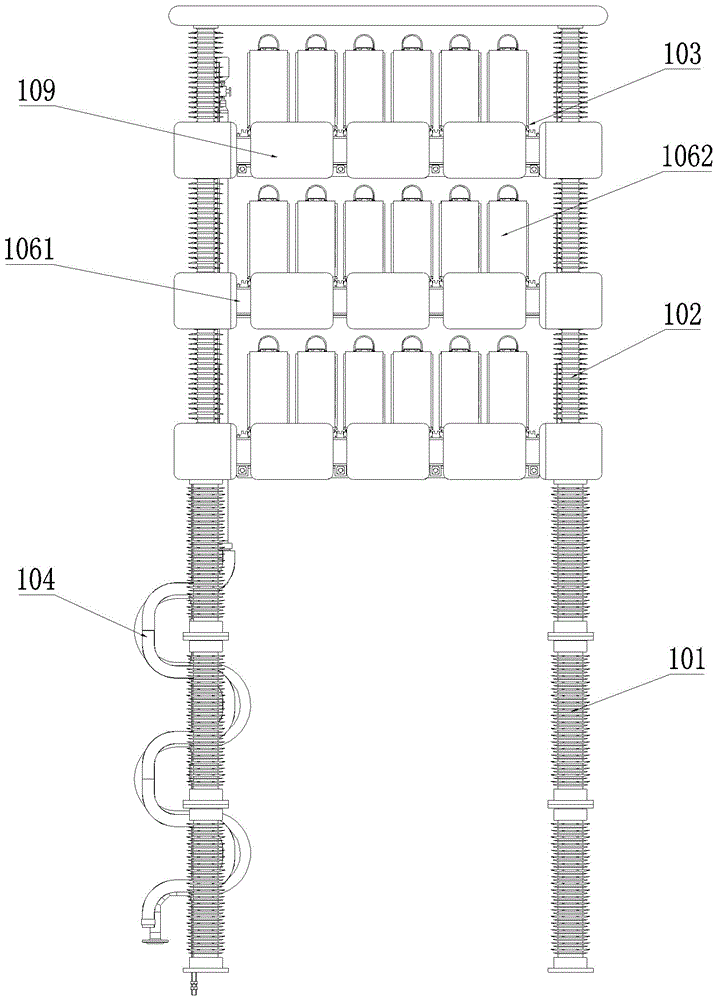

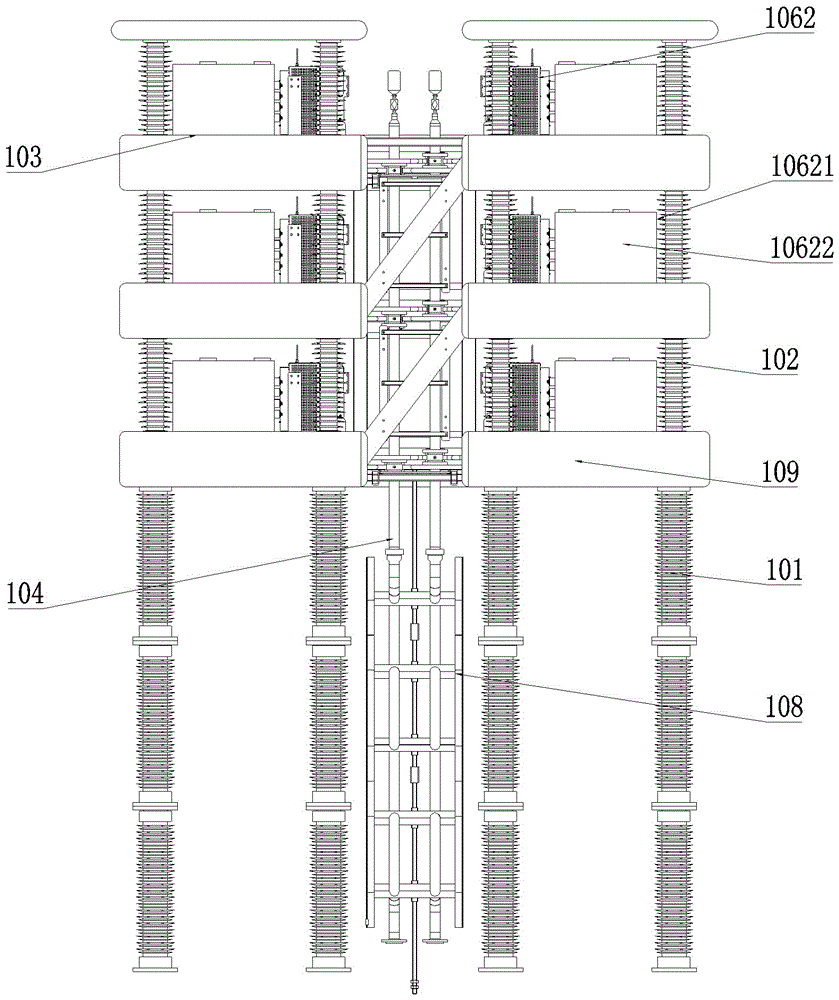

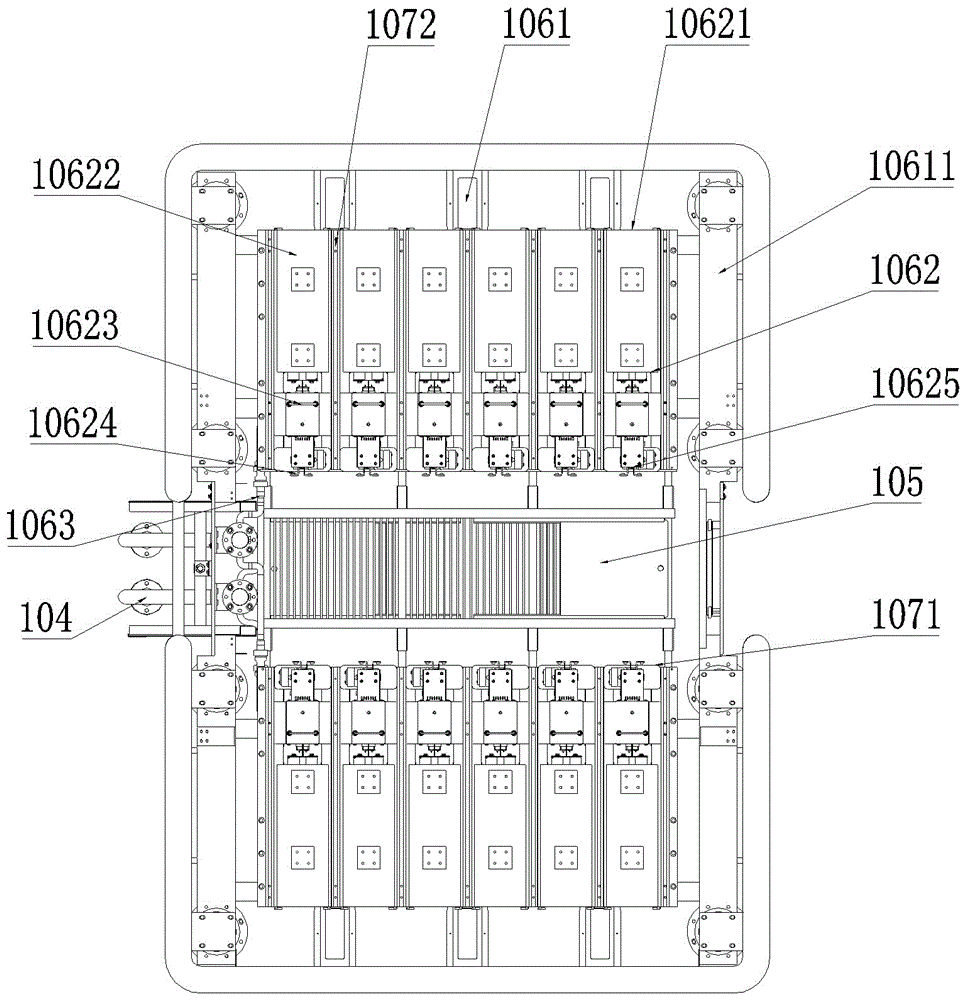

[0033] Embodiment 1 of the valve tower in the present invention: as Figure 1 to Figure 8As shown, the valve tower is a new type of flexible direct current transmission supporting valve tower. In this embodiment, the valve tower is a single tower structure. Water pipe 104, each valve group layer 103 is composed of two diverter valve assemblies arranged symmetrically front and back and an inspection platform 105 installed between them, each diverter valve assembly consists of a frame 1061 and submodules 1062 assembled on it, The branch water pipe 1063 is composed of five sub-modules 1062, which are arranged on the frame 1061 from left to right to form a valve section. The side of the mechanism close to the maintenance platform 105 is the drawing opening 1071 for the sub-module 1062 to enter and exit. The drawing openings 1071 of each guide mechanism are on the same side in the front and rear direction on the frame 1061, and are flush with each other on the left and right; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com