A preparation method of bone graft material coated with adiponectin

A technology of adiponectin and bone grafting, applied in the field of medical biomaterial preparation, can solve the problems of refractory degradation, poor biological activity, poor bone powder strength, etc., and achieve the effects of easy degradation, high biological activity, and increased bone strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of the bone graft material coated with adiponectin comprises the following steps:

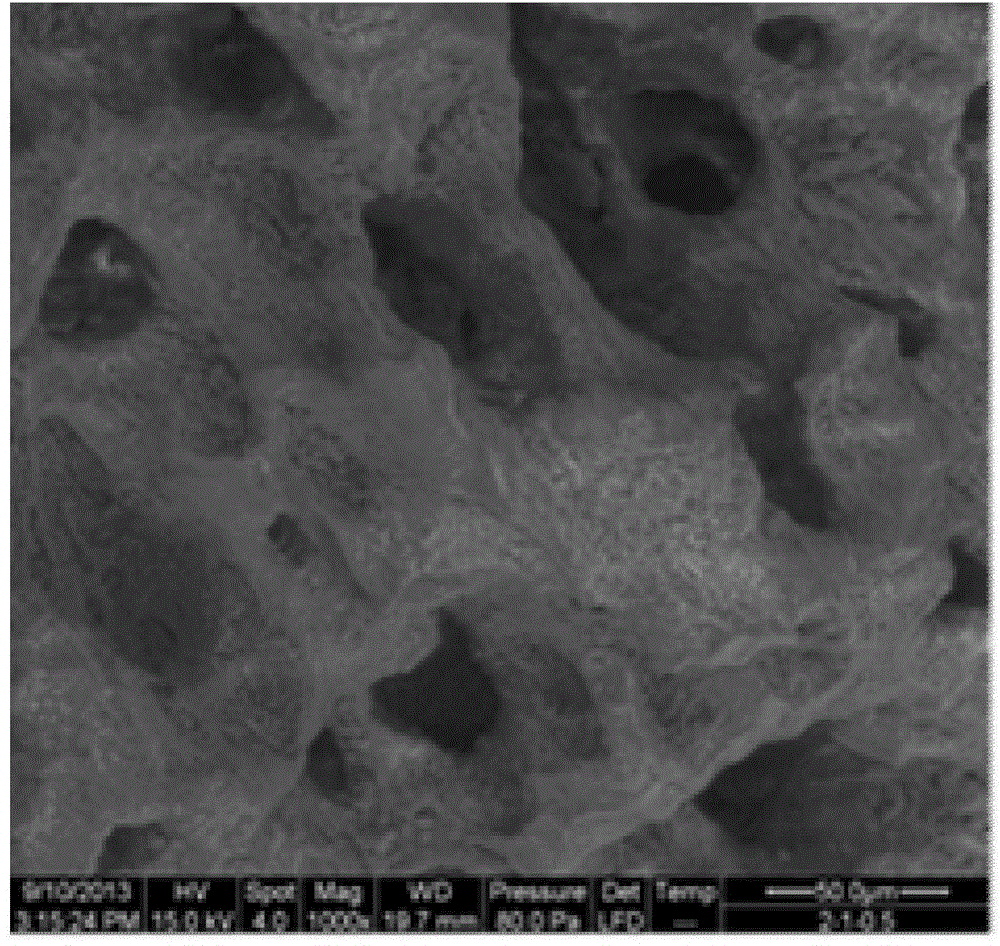

[0030] Step 1, prepare modified calcined bone material; select the joint head of newborn calf as the bone raw material, fully wash with deionized water and basically remove collagen by physical or biochemical methods; then use diammonium hydrogen phosphate to balance according to the chemical reaction Modify the bone matrix (bone salt) with the formula ratio, so that the Ca / P atomic ratio of the bone matrix is reduced to 1.55; then the modified bone material is calcined at a temperature of 1000°C to completely remove the immune antigenicity of the bone material , to obtain a modified calcined bone material; in the obtained modified calcined bone material, hydroxyapatite (HA):β tricalcium phosphate (βTCP)=1:3.

[0031] Step 2, take 2500mg molecular weight at 2.5x10 5 Carboxymethyl chitosan, the carboxymethyl chitosan is dissolved in 60ml volume fraction of 2% ace...

Embodiment 2

[0036] The preparation method of the bone graft material coated with adiponectin comprises the following steps:

[0037] Step 1, prepare modified calcined bone material; select the epiphysis of the tibia as the bone material, fully wash with deionized water and basically remove collagen by physical or biochemical methods; then use ammonium dihydrogen phosphate to balance according to the chemical reaction Modification of the bone matrix (bone salt) by formula matching, so that the Ca / P atomic ratio of the bone matrix is reduced to 1.5; then the modified bone material is calcined at a temperature of 800°C to completely remove the immunoantigenicity of the bone material , to obtain modified calcined bone material.

[0038] Step 2, take 2000mg molecular weight in 2x10 5 Carboxymethyl chitosan, said carboxymethyl chitosan is dissolved in 70ml volume fraction is 2% acetic acid solution to form carboxymethyl chitosan solution; Said solution is mixed with 1000mg modified calcined ...

Embodiment 3

[0043] The preparation method of the bone graft material coated with adiponectin comprises the following steps:

[0044] Step 1, prepare modified calcined bone material; select the joint head of newborn calf as the bone material, thoroughly wash with deionized water and basically remove collagen by physical or biochemical methods; then use phosphoric acid to formulate according to the chemical reaction balance equation Modified the bone matrix (bone salt) to reduce the Ca / P atomic ratio of the bone matrix to 1.66; then calcined the modified bone material at a temperature of 1100°C to completely remove the immunoantigenicity of the bone material, and obtained Modification of calcined bone material.

[0045] Step 2, take 3000mg molecular weight in 3x10 5 Carboxymethyl chitosan, the carboxymethyl chitosan is dissolved in 80ml volume fraction of 2% acetic acid solution to form a carboxymethyl chitosan solution; the solution is mixed with 1000mg modified calcined bone material to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com