Floating-type loaded sulfite microcapsules, preparation method thereof and method for preventing fruit wine hop disease by using the microcapsules

A sulfite and microcapsule technology, applied in the field of fermentation engineering, can solve problems such as factors that interfere with wine quality, increase workload and difficulty in fruit wine maintenance, and affect the quality of fruit wine, and achieve the effect of preventing fruit wine hop disease.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]1) Weigh a certain amount of sodium alginate, dissolve it in an appropriate amount of distilled water, and prepare an aqueous solution of sodium alginate (ALG) with a concentration of 20% by mass; then mix potassium metabisulfite crystals and CaCO 3 Add it into the aqueous solution of sodium alginate, stir evenly to obtain the mixed solution A; among them, potassium metabisulfite (PMB), CaCO 3 The mass ratio with sodium alginate aqueous solution is 1:0.05:1;

[0034] 2) Weigh a certain amount of citric acid crystals, dissolve them in an appropriate amount of distilled water, and prepare a citric acid aqueous solution with a concentration of 10% by mass; then add CaCl 2 Crystals are added to aqueous citric acid solution and stirred evenly to obtain solution B, wherein CaCl in solution B 2 The mass percentage concentration is 40%;

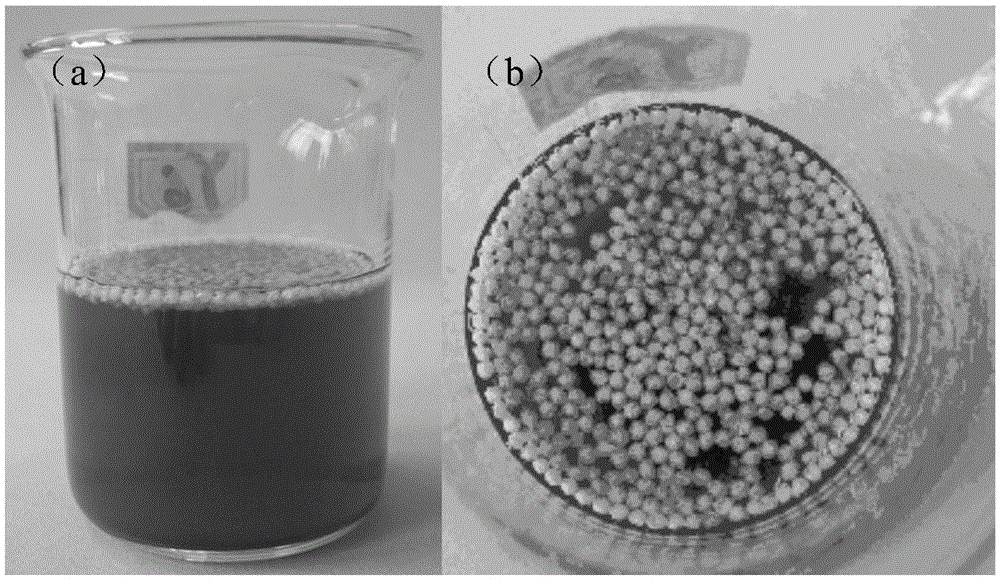

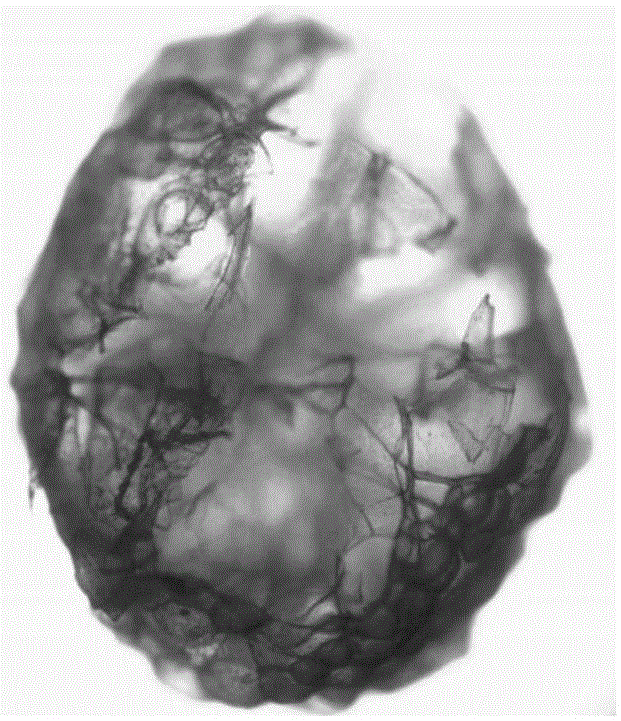

[0035] 3) At room temperature, put solution B in a beaker, draw mixed solution A with a 1mL syringe, and drop mixed solution A into solution...

Embodiment 2

[0038] 1) Weigh a certain amount of sodium alginate, dissolve it in an appropriate amount of distilled water, and prepare a sodium alginate (ALG) aqueous solution with a concentration of 30% by mass; then mix potassium metabisulfite crystals and CaCO 3 Add it into the sodium alginate aqueous solution, stir evenly to obtain the mixed solution A; wherein potassium metabisulfite, CaCO 3 The mass ratio with sodium alginate aqueous solution is 0.9:0.05:1;

[0039] 2) Weigh a certain amount of citric acid crystals, dissolve them in an appropriate amount of distilled water, and prepare a citric acid aqueous solution with a concentration of 30% by mass; then add CaCl 2 Crystals are added to aqueous citric acid solution and stirred evenly to obtain solution B, wherein CaCl in solution B 2 The mass percentage concentration is 35%;

[0040] 3) At room temperature, put solution B in a beaker, draw mixed solution A with a 1mL syringe, and drop mixed solution A into solution B under 400r / ...

Embodiment 3

[0043] 1) Weigh a certain amount of sodium alginate, dissolve it in an appropriate amount of distilled water, and prepare an aqueous solution of sodium alginate (ALG) with a concentration of 25% by mass; then add sulfurous acid and CaCO 3 Add it into the sodium alginate aqueous solution, stir well to obtain the mixed solution A; wherein sulfurous acid, CaCO 3 The mass ratio with sodium alginate aqueous solution is 0.8:0.05:1;

[0044] 2) Weigh a certain amount of citric acid crystals, dissolve them in an appropriate amount of distilled water, and prepare a citric acid aqueous solution with a concentration of 20% by mass; then add CaCl 2 Crystals are added to aqueous citric acid solution and stirred evenly to obtain solution B, wherein CaCl in solution B 2 The mass percentage concentration is 36%;

[0045] 3) At room temperature, put solution B in a beaker, draw mixed solution A with a 1mL syringe, and drop mixed solution A into solution B under 350r / min magnetic stirring to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| load ratio | aaaaa | aaaaa |

| floating rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com