Method for electrodepositing inhibitor anion intercalation hydrotalcite film on surface of magnesium alloy

A technology of anion intercalation and corrosion inhibitor, applied in the direction of electrolytic inorganic material coating, etc., can solve the problems of insufficient mechanical properties, weak bonding force between the film and the substrate, etc., and achieve the effect of good bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] Preparation of corrosion-inhibiting anion-intercalated hydrotalcites:

[0015] At room temperature, the soluble nitrate of +2-valent and +3-valent metal ions is prepared into an aqueous solution with distilled water, and the molar ratio of +2-valent and +3-valent metal ions is 1.8 to 2.2, and the +2-valent metal ion can be Mg 2+ , Zn 2+ , Ni 2+ , Ce 2+ , Fe 2+ ;+3 valent metal ion can be Al 3+ , Cr 3+ , Ce 3+ , Fe 3+ , Ti 3+ ; In addition, take a certain amount of sodium salt of the corrosion inhibitor anion to be inserted into the hydrotalcite layer, the molar ratio of the anion to the +3 valent metal ion is 1.5 to 2.0, and the anion can be VO 3 - / V 10 o 28 6- 、MoO 4 2- / Mo 7 o 24 6- 、WO 4 2- , CrO 4 2- Or phosphomolybdate; choose NaOH solution or ammonia as the precipitant. Add the sodium salt solution of the anion to be inserted between the hydrotalcite layers into the container, then drop the soluble nitrate solution of +2-valent and +3-valent...

example 1

[0021]Example 1: Preparation of vanadate intercalated zinc aluminum hydrotalcite film

[0022] Steps: Weigh 1.0-5.0 g of the fully ground hydrotalcite sample, place it in a conical flask filled with 100 mL of deionized water, ultrasonically disperse for 30-60 min, soak for 7 days, and then ultrasonically disperse for 10-20 min. Take 50-100mL of the suspension, add NaVO 3 and AlCl 3 , control VO 3 - The molar concentration of Cl is 0.005~0.01mol / L, and the Cl - The molar concentration is 0.002-0.006mol / L, and it is transferred into the three-electrode system, and the pH value is controlled to be 5.5-6.5; 2 , to remove dissolved oxygen and CO from the suspension 2 ; After 10 minutes, connect the electrode system, the magnesium alloy sample is used as the working electrode, and the platinum sheet is used as the counter electrode. Electrochemical cycle scanning is used. The scanning rate is 5 ~ 30mV / s, and the scanning range is -1.65 ~ -0.50V vs Ref. The number of cycles 8 t...

example 2

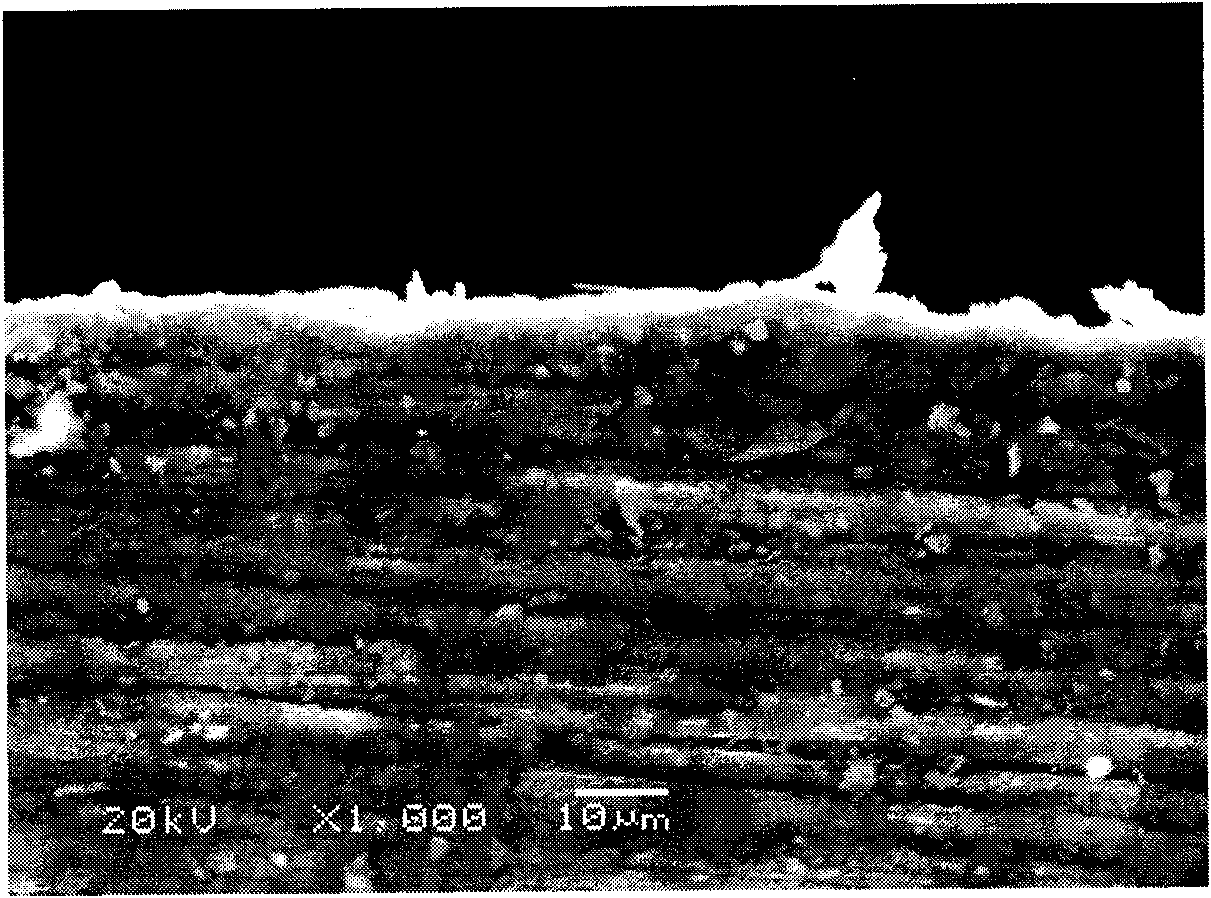

[0023] Example 2: Preparation of molybdate intercalated magnesium aluminum hydrotalcite film

[0024] Steps: Weigh 1.0-5.0 g of the fully ground hydrotalcite sample, place it in a conical flask filled with 100 mL of deionized water, ultrasonically disperse for 30-60 min, soak for 7 days, and then ultrasonically disperse for 10-20 min. Take 50-100mL of the suspension, add Na 2 MoO 4 , to control MoO 4 2- The molar concentration is 0.005~0.01mol / L, and it is transferred into the three-electrode system, and the pH value is controlled to be 7.5; 2 , to remove dissolved oxygen and CO from the suspension 2 ; After 10 minutes, connect the electrode system, the magnesium alloy sample is used as the working electrode, and the platinum sheet is used as the counter electrode. Electrochemical cycle scanning is used. The scanning rate is 5 ~ 30mV / s, the scanning range is -1.60 ~ -0.50V vs Ref, and the number of cycles 5 times, the film thickness is 8 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com