A stainless steel extraction stirring rod and preparation method thereof

A stainless steel rod and stirring rod technology, applied in the field of analytical chemistry, can solve the problems of easy destruction of the glass layer, complicated preparation, and hard-to-extract materials are fixed on the stainless steel rod, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

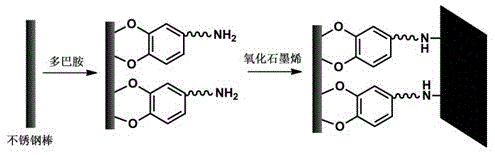

[0025] 1) Weigh 20 mg of dopamine, dissolve it in 10 mL of Tris buffer with a concentration of 10 mmol / L, adjust the pH to 8.5, inject oxygen, and stir until the solution turns light reddish brown.

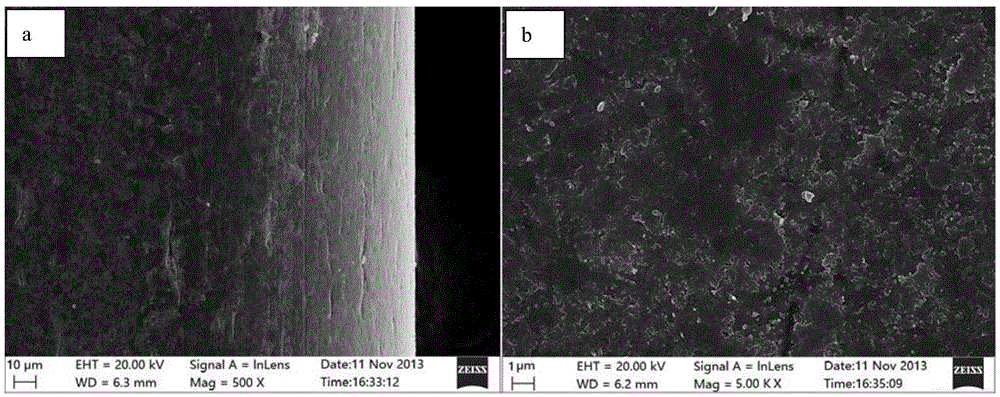

[0026] 2) Take a stainless steel rod with a diameter of about 0.5 mm and a length of 3 cm, fully wash it with methanol, and dry it; immerse it in the dopamine solution prepared in 1), and let it react at room temperature for 10 hours; take it out, wash it with water, and dry it in an oven. Obtain polydopamine-modified stainless steel rods.

[0027] 3) Prepare a 1 mg / mL graphene oxide aqueous solution, immerse the above-mentioned polydopamine-modified stainless steel rod in it, seal the reaction vessel, and place it in a water bath at 60°C for 6 hours; take it out, wash it with water, and place it in an oven. Heating at 65°C for 2h;

[0028] 4) Take out the stainless steel rod, repeat the above step 2) and step 3) twice in order to obtain a three-layer graphene-modified stainless ...

Embodiment 2

[0031] 1) Weigh 10 mg of dopamine, dissolve it in 10 mL of Tris buffer with a concentration of 10 mmol / L, adjust the pH to 9, and shake the solution until the solution is light reddish brown.

[0032] 2) Take a stainless steel rod with a diameter of about 2 mm and a length of 5 cm, fully wash it with methanol, and dry it; immerse it in the dopamine solution prepared in 1), and leave it to react at room temperature for 15 hours; take it out, wash it with water, and dry it in an oven to obtain Polydopamine-modified stainless steel rods.

[0033] 3) Prepare a 2 mg / mL graphene oxide aqueous solution, immerse the above-mentioned polydopamine-modified stainless steel rod in it, seal it, and place it in a water bath at 65°C for 10 hours; take it out, wash it with water, place it in an oven, and heat it at 75°C After 3 hours, a single-layer graphene-modified stainless steel extraction stirring rod was obtained.

Embodiment 3

[0035] 1) Weigh 20 mg of dopamine, dissolve it in 10 mL of Tris buffer with a concentration of 10 mmol / L, adjust the pH to 8.5, inject oxygen, and stir until the solution turns light reddish brown.

[0036] 2) Take a stainless steel rod with a diameter of about 0.5 mm and a length of 3 cm, fully wash it with methanol, and dry it; immerse it in the dopamine solution prepared in 1), and let it react at room temperature for 12 hours; take it out, wash it with water, and dry it in an oven. Obtain polydopamine-modified stainless steel rods.

[0037] 3) Prepare a 1 mg / mL graphene oxide aqueous solution, immerse the above-mentioned polydopamine-modified stainless steel rod in it, seal the reaction vessel, and place it in a water bath at 60°C for 8 hours; take it out, wash it with water, and place it in an oven. Heating at 70°C for 2h;

[0038] 4) Take out the stainless steel rod, and repeat step 2) and step 3) 5 times in order to obtain a 6-layer graphene-modified stainless steel ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com