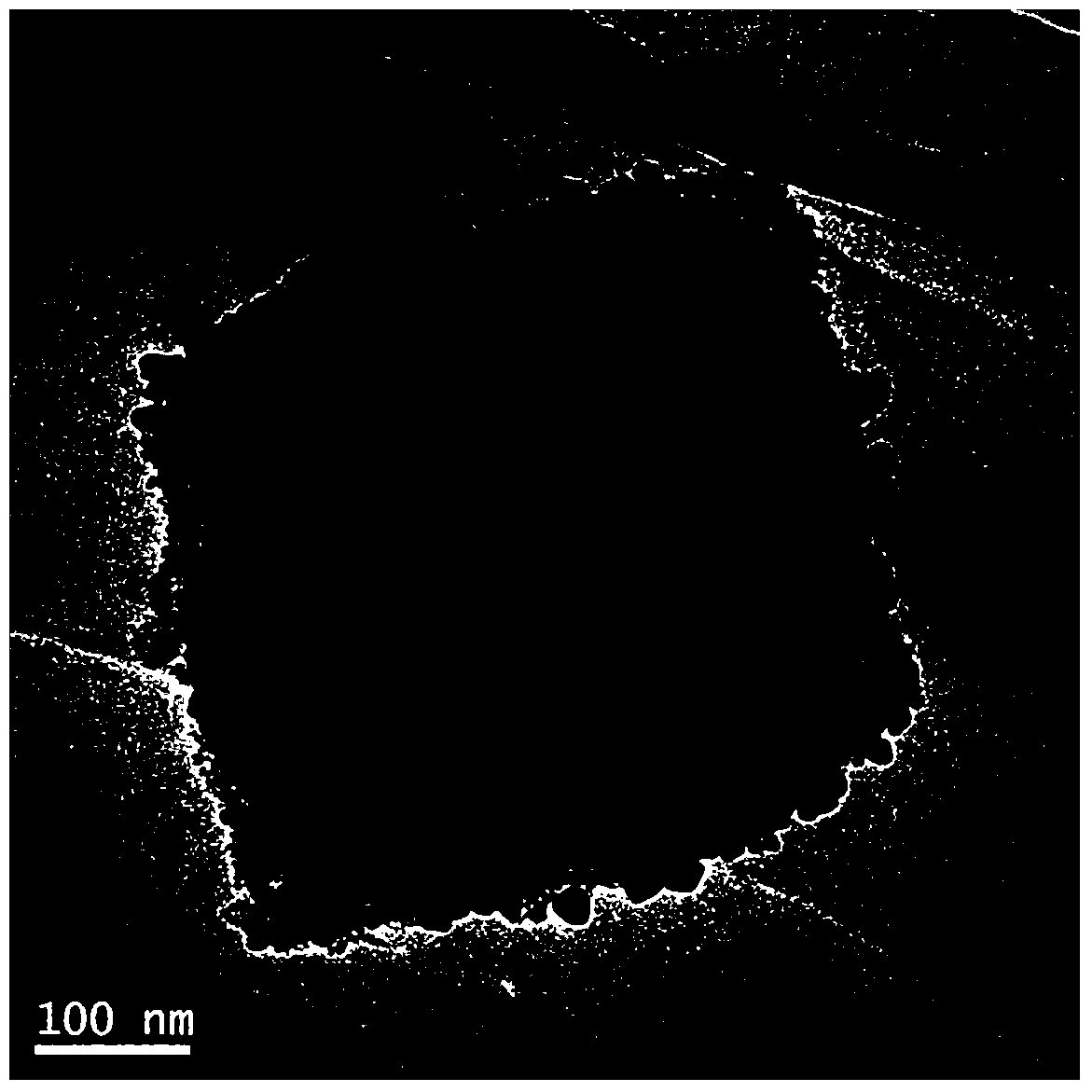

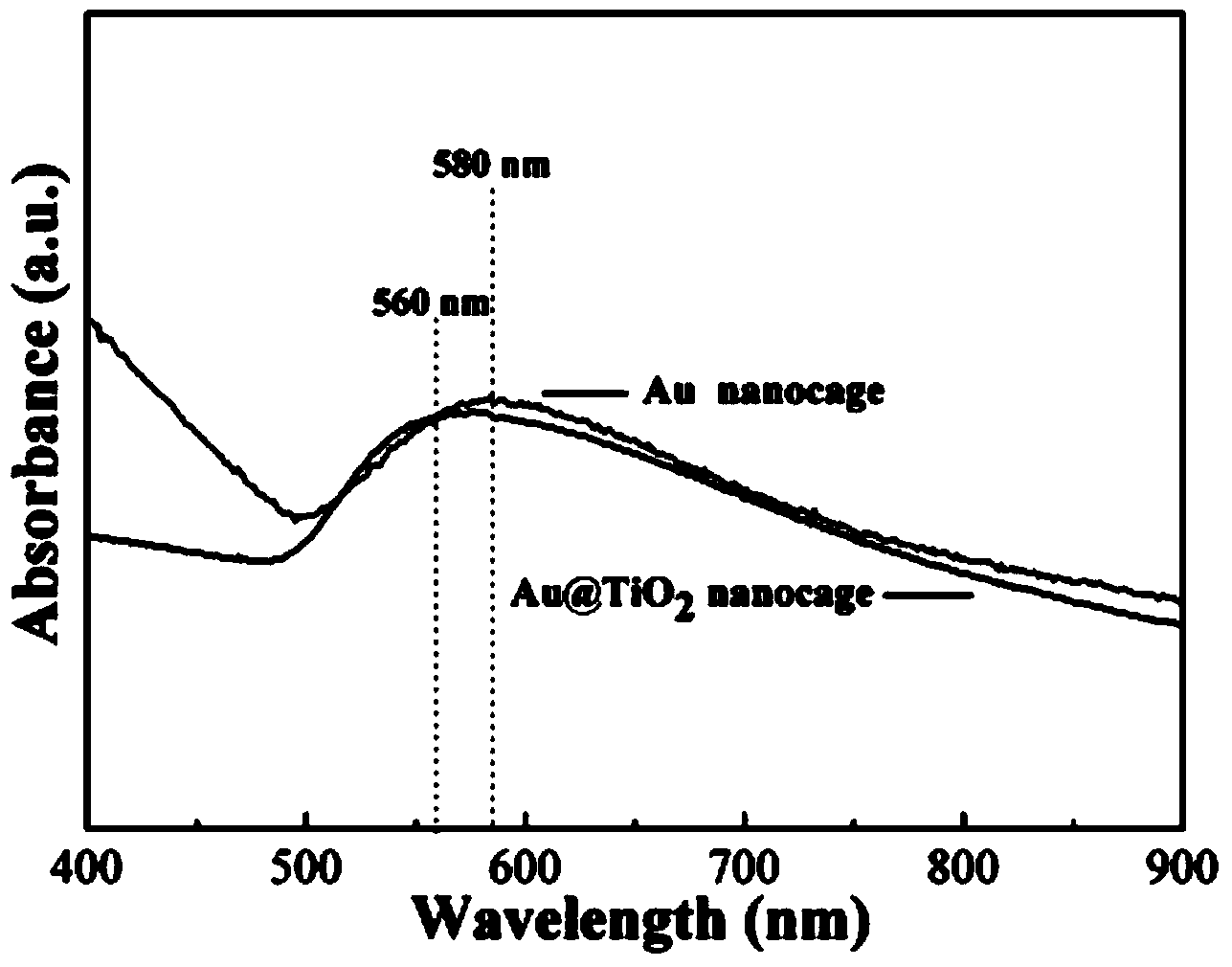

Composite catalyst with titanium dioxide coated gold nanocage structure, as well as preparation method and application of composite catalyst

A composite catalyst, gold nanocages technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as the difficulty of uniformly coating oxide layers, etc. Achieve significant degradation effect and accelerate the effect of catalytic reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of Cu by ascorbic acid reduction method 2 O octahedron

[0034] Weigh CuCl in turn 2 ·H 2O0.1704g, 0.1g sodium citrate, and 3.4g PVP were dissolved in 100ml deionized water, stirred until uniform, and then 10mL NaOH solution with a concentration of 2mol / L was added dropwise and continued to stir. After 0.5 h, 10 mL of 0.6 mol / L ascorbic acid was added dropwise to the aforementioned solution. Finally, the mixed solution was matured at 30 °C for 2.5 h, cooled naturally to room temperature, centrifuged, and washed with ethanol and deionized water three times to obtain Cu 2 O octahedron.

[0035] (2)Cu 2 OTiO 2 preparation of

[0036] Weigh 0.01 g of prepared Cu 2 O octahedron into 25mL deionized water, with 0.6mL of 0.02mol / L TiF 4 Mix the aqueous solution and stir evenly for 10 minutes. The mixed solution was transferred to a 50 mL hydrothermal kettle, heated at 180 °C for 1 h, cooled naturally, centrifuged, washed with ethanol and water three ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com