Preparation method of acetoacetanilide compound

A technology of acetoacetanilide and aniline compounds, which is applied in the field of compound preparation, can solve the problems of low melting point and unfavorable application of acetoacetanilide compounds, and achieve the effect of low energy consumption and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a kind of preparation method of acetoacetanilide compound, comprising:

[0021] Under oxygen-free conditions, aniline compounds and diketene are subjected to a diacetylation reaction in an organic solvent to obtain acetoacetanilide compounds.

[0022] The acetoacetanilide compound prepared by the method provided by the invention has a relatively high melting point, which is beneficial to the application of the acetoacetanilide compound. In addition, the acetoacetanilide compounds prepared by the method provided by the invention are not easy to agglomerate, and the preparation method of the acetoacetanilide compounds provided by the invention has low energy consumption.

[0023] In the present invention, the aniline compound and diketene are subjected to a diacetylation reaction in an organic solvent under an oxygen-free condition to obtain the acetoacetanilide compound. In the present invention, the aniline compound is preferably mixed with an or...

Embodiment 1

[0036] After replacing the air in the reactor with nitrogen, seal the reactor, add 2000L of ethanol and 400kg of 2,4-dimethylaniline to the reactor at 23°C and a stirring speed of 80 rpm After mixing, add 292kg of diketene to the obtained mixture within 1.5 hours for diacetylation reaction; heat the obtained reaction product at 40°C for 3 hours; cool the obtained heat-preserved product to 6°C, filter and dry , to obtain acetoacetyl 2,4-xylaniline.

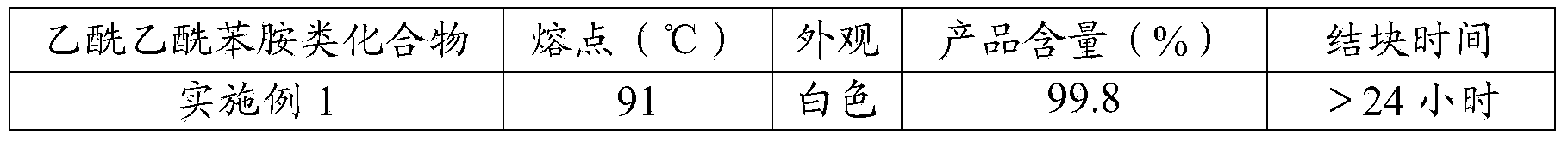

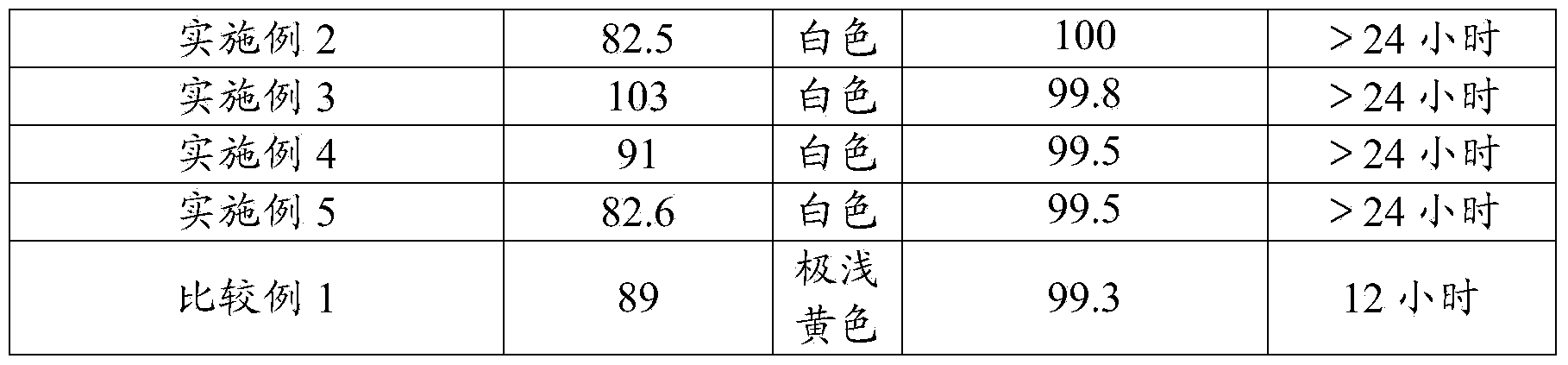

[0037] The appearance, melting point, product content and agglomeration time of the acetoacetyl 2,4-xylaniline obtained in Example 1 of the present invention were tested according to the method described in the above technical scheme. The test results are shown in Table 1, which is the embodiment of the present invention. The test results of the appearance, melting point, product content and caking time of the acetoacetanilide compounds obtained in Examples and Comparative Examples.

[0038] Test the yield of the acetoacetyl 2,4-x...

Embodiment 2

[0040] After replacing the air in the reactor with nitrogen, seal the reactor, add 2000 L of ethanol and 400 kg of aniline to the reactor at 23° C. and a stirring speed of 80 rpm, and mix them within 1.5 hours. 380 kg of diketene was added to the obtained mixture to carry out diacetylation reaction; the obtained reaction product was subjected to heat preservation treatment at 40° C. for 3 hours; the obtained heat preservation treatment product was cooled to 6° C., filtered and dried to obtain acetoacetanilide.

[0041] The appearance, melting point, product content and caking time of the acetoacetanilide obtained in Example 2 of the present invention were tested according to the method described in the above technical solution, and the test results are shown in Table 1.

[0042] The yield of the method for preparing acetoacetanilide provided in Example 2 of the present invention was tested according to the method described in the above technical solution, and the test result sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com