Shoemaking material, shoe soles and shoe pads prepared from material and preparation method of material

A technology of insoles and raw rubber, which is applied to soles, applications, footwear, etc. It can solve the problems of hot and humid inside shoes, uncomfortable wearing, and inability to discharge, and achieve good cushioning and shockproof performance, excellent air permeability, and keep feet dry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

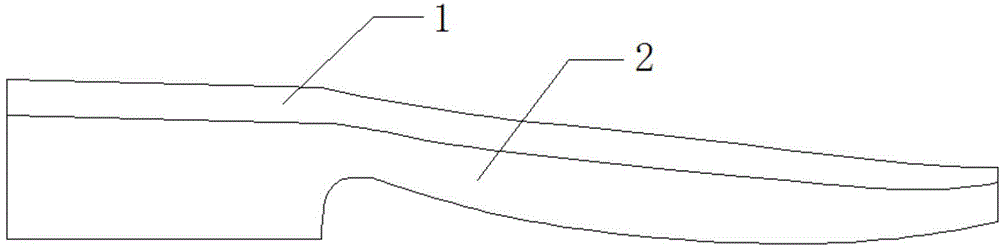

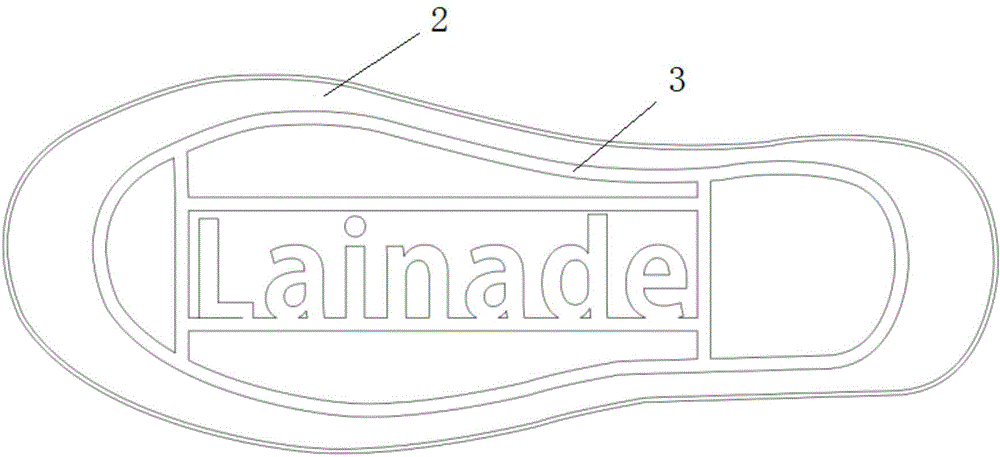

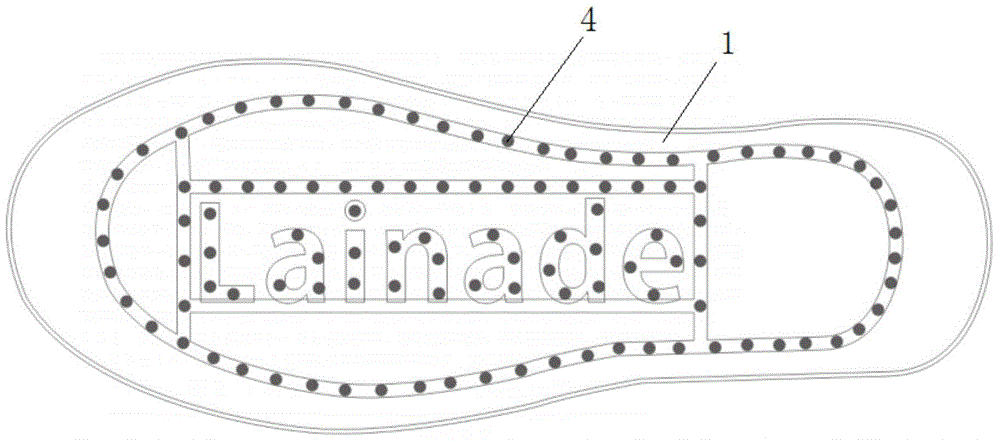

[0033] The embodiment of the present invention also provides the sole prepared by using the above-mentioned shoe-making material, and the preparation method of the sole comprises the following steps:

[0034] mixing the components of the shoemaking material evenly, and granulating to obtain granules;

[0035] Take an appropriate amount of the granules and add them to the shoe mold, seal and heat to 170-180° C., and release the mold for 12-20 minutes. After demoulding, the foamed rubber sole is obtained.

[0036] The obtained sole has a porous structure and excellent air permeability, which is conducive to the dissipation of water vapor in the shoe and keeps the feet dry; the cushioning and shockproof performance is good, and the shoe sole is soft and comfortable. Contains nano-silver material, nano-silver has high antibacterial activity and is safe to use, nano-silver is evenly distributed in the prepared sole or insole, and has antibacterial properties; contains magnetic powd...

Embodiment 1

[0046] In parts by weight, weigh the following ingredients: 90 parts of natural rubber, 90 parts of EVA with a VA content of 18, 610 parts of AC foaming agent, 170 parts of DCP crosslinking agent, 15 parts of zinc oxide, 13 parts of stearic acid, calcium carbonate 5 parts, 9 parts of rubber powder, 12 parts of nano-silver, 75 parts of negative ion powder, 4 parts of magnetic powder, and 1 part of pigment; among them, the purity of nano-silver is more than 99.95%, and the particle size is 8-12nm; the particle size of negative ion powder is 100-200nm Nano negative ion powder; magnetic powder is 80-100 mesh;

[0047] Mixing the above-mentioned components of the shoe-making material evenly, and granulating to obtain particles with a particle size of 1-2 mm;

[0048] Take an appropriate amount of granules and add them to the shoe mold, seal and heat to 170°C, and release the mold for 12 minutes. After demoulding, the rubber foam sole is obtained, and the sole is directly used for s...

Embodiment 2

[0050] In parts by weight, weigh the following ingredients: 100 parts of natural rubber, 95 parts of EVA with VA content of 18, 615 parts of AC foaming agent, 176 parts of DCP crosslinking agent, 16 parts of zinc oxide, 14 parts of stearic acid, calcium carbonate 6 parts, 10 parts of rubber powder, 12 parts of nano-silver, 80 parts of negative ion powder, 5 parts of magnetic powder, 4 parts of pigment; among them, the purity of nano-silver is more than 99.95%, and the particle size is 8-12nm; the particle size of negative ion powder is 100-200nm Nano negative ion powder; magnetic powder is 120-140 mesh;

[0051] Mixing the above-mentioned components of the shoemaking material evenly, and granulating to obtain particles with a particle size of 2-3 mm;

[0052] Take an appropriate amount of granules and add them to the shoe mold, seal and heat to 175°C, and continue to release the mold for 16 minutes. After demolding, the rubber foam sole is obtained;

[0053] The raw rubber so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com