Test method for simulation of iron ore direct-reduction by coke reactive determination device

A technology of measuring device and test method, applied in the field of metallurgy, can solve problems such as inaccurate test data, and achieve the effects of simple operation, easy promotion and high efficiency of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

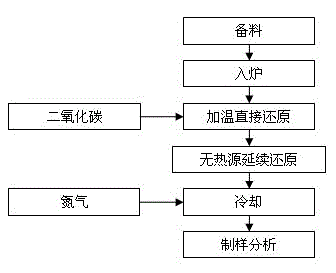

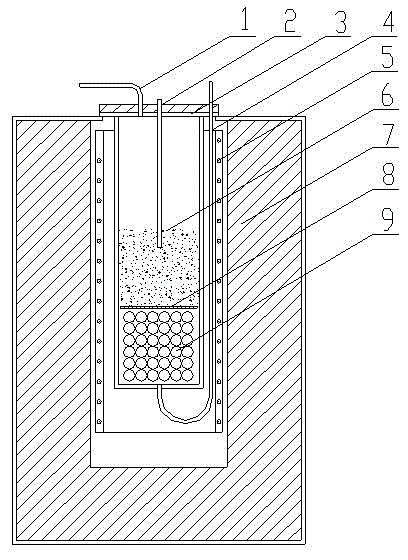

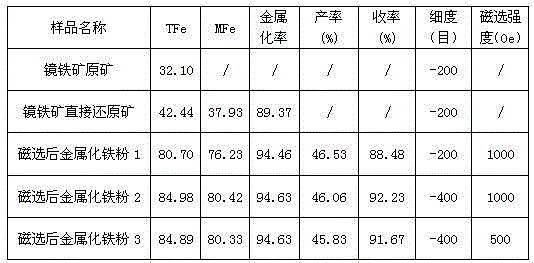

[0034] A test method utilizing a coke reactivity measuring device to simulate the direct reduction of iron ore, comprising the following steps:

[0035] Step 1: Weigh 230g of specularite raw ore with a particle size of 8-15mm, 50g of semi-coke with a particle size of 1-3mm and a fixed carbon content of 73%, 50g of semi-coke with a particle size of 3-5mm and a fixed carbon content of 73% , 40g of semi-coke with a particle size of 1-3mm was laid on the bottom layer of the high-temperature reaction tube, 115g of specularite ore was laid on it, 30g of mixed semi-coke was laid on the middle layer, and 115g of specularite ore was laid, and the remaining 30g Mixed semi-coke lays the upper layer;

[0036] Step 2: Put the high-temperature reaction tube into the high-temperature reaction furnace, connect the gas pipeline, and quickly raise the temperature of the high-temperature reaction furnace to 1100°C, and the reaction time is 60 minutes; when the temperature reaches 800°C, use an a...

Embodiment 2

[0046] A test method utilizing a coke reactivity measuring device to simulate the direct reduction of iron ore, comprising the following steps:

[0047] Step 1: Weigh 200g of iron concentrate oxidized pellets, 45g of semi-coke with a particle size of 1-3mm and a fixed carbon content of 80%, 45g of semi-coke with a particle size of 3-5mm, and a fixed carbon content of 80%. Lay 3-5mm semi-coke on the bottom layer of the high-temperature reaction tube, lay 100g of iron concentrate oxidized pellets on it, then lay 30g of mixed semi-coke on the middle layer, and then lay 100g of specular iron ore. 30g semi-coke of ~3mm is laid on the upper layer;

[0048] Step 2: Put the high-temperature reaction tube into the high-temperature reaction furnace, connect the gas pipeline, and quickly raise the temperature of the high-temperature reaction furnace to 1170°C, and the reaction time is 120 minutes; when the temperature reaches 800°C, use an air bag with a capacity of 2L to start collectin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com