Method for preparing non-polar surface or semi-polar surface single crystal semiconductor self-supporting substrate

A single crystal semiconductor and self-supporting substrate technology, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of inability to peel off large-sized substrates, complex peeling process, and reduce substrate costs, etc. problems, to promote research and industrialization, improve production efficiency and yield, and solve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

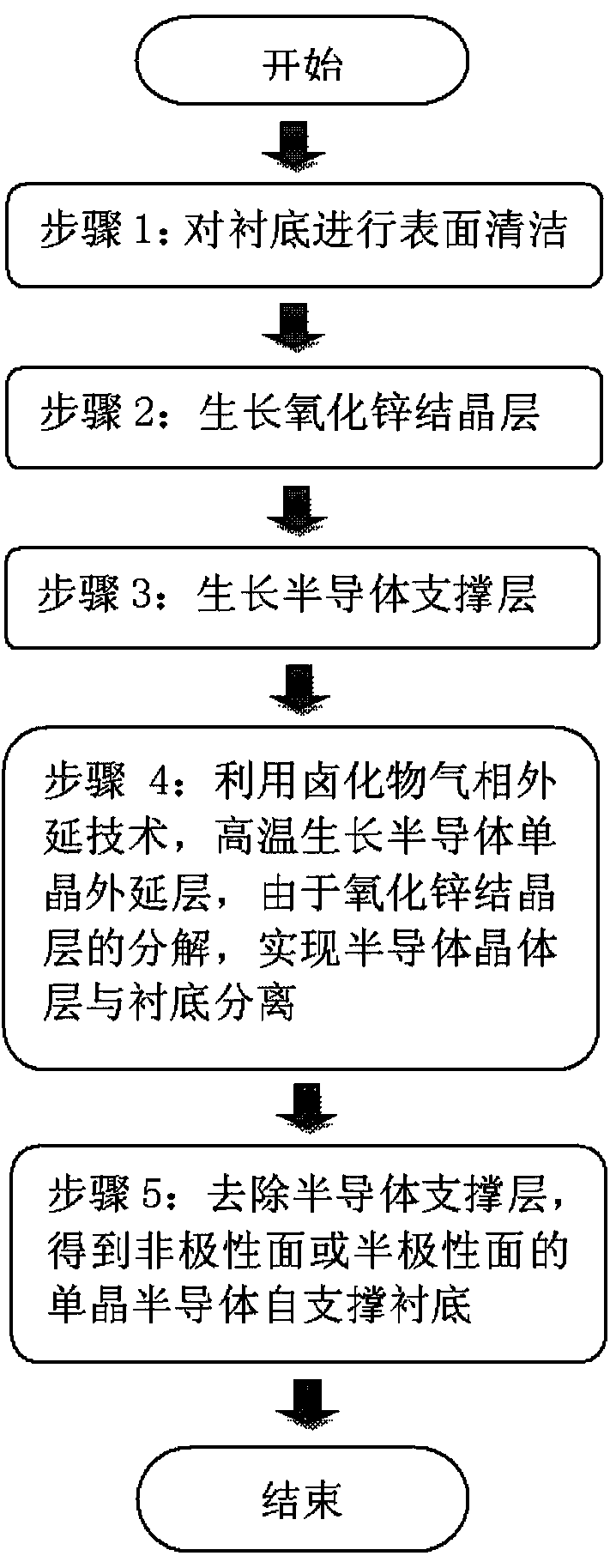

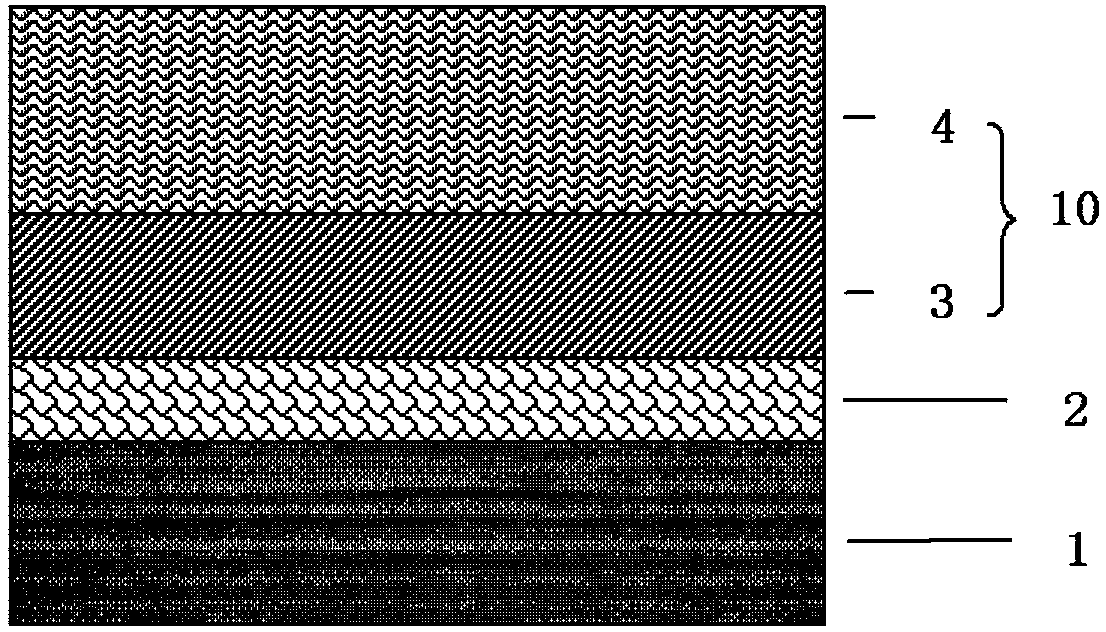

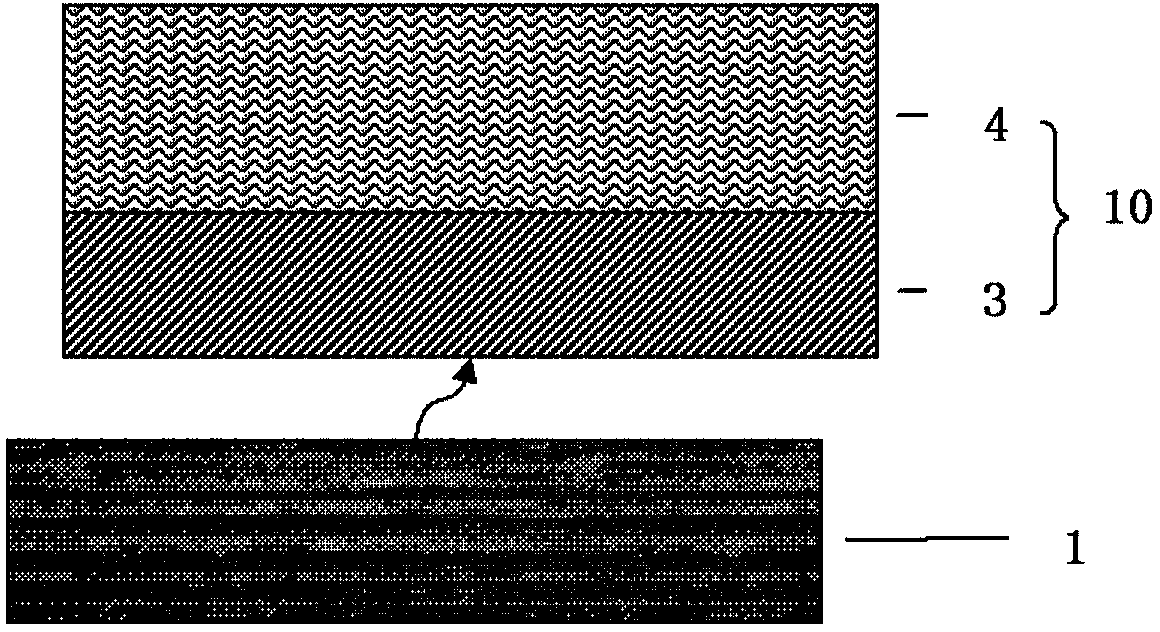

[0017] See figure 1 , And refer to Figure 2-Figure 4 As shown, the present invention provides a method for preparing a non-polar surface or semi-polar surface single crystal semiconductor self-supporting substrate, which includes the following steps:

[0018] Step 1: Take a substrate 1, clean the surface, and place it in the growth chamber of the material growth equipment. The substrate 1 is a non-polar or semi-polar substrate, and the material of the substrate 1 is an R surface. Sapphire substrate, M surface Sapphire substrate, Surface silicon carbide substrate or Surface silicon carbide substrate; the material growth equipment is a metal organic chemical vapor deposition equipment or a pulsed laser deposition equipment.

[0019] Step 2: Growing a zinc oxide crystal layer 2 on the substrate 1 as a sacrificial layer, and the thickness of the zinc oxide crystal layer 2 is 100 nm to 500 nm;

[0020] The zinc oxide crystal layer 2 can be prepared by metal-organic chemical vapor dep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com