Hydrolysis and fermentation process for animal feed production

A technology of animal feed and production process, applied in animal feed, animal feed, fermentation, etc., can solve uneconomical problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Acid hydrolysis and enzyme hydrolysis of thin stillage of embodiment 1

[0062] introduce

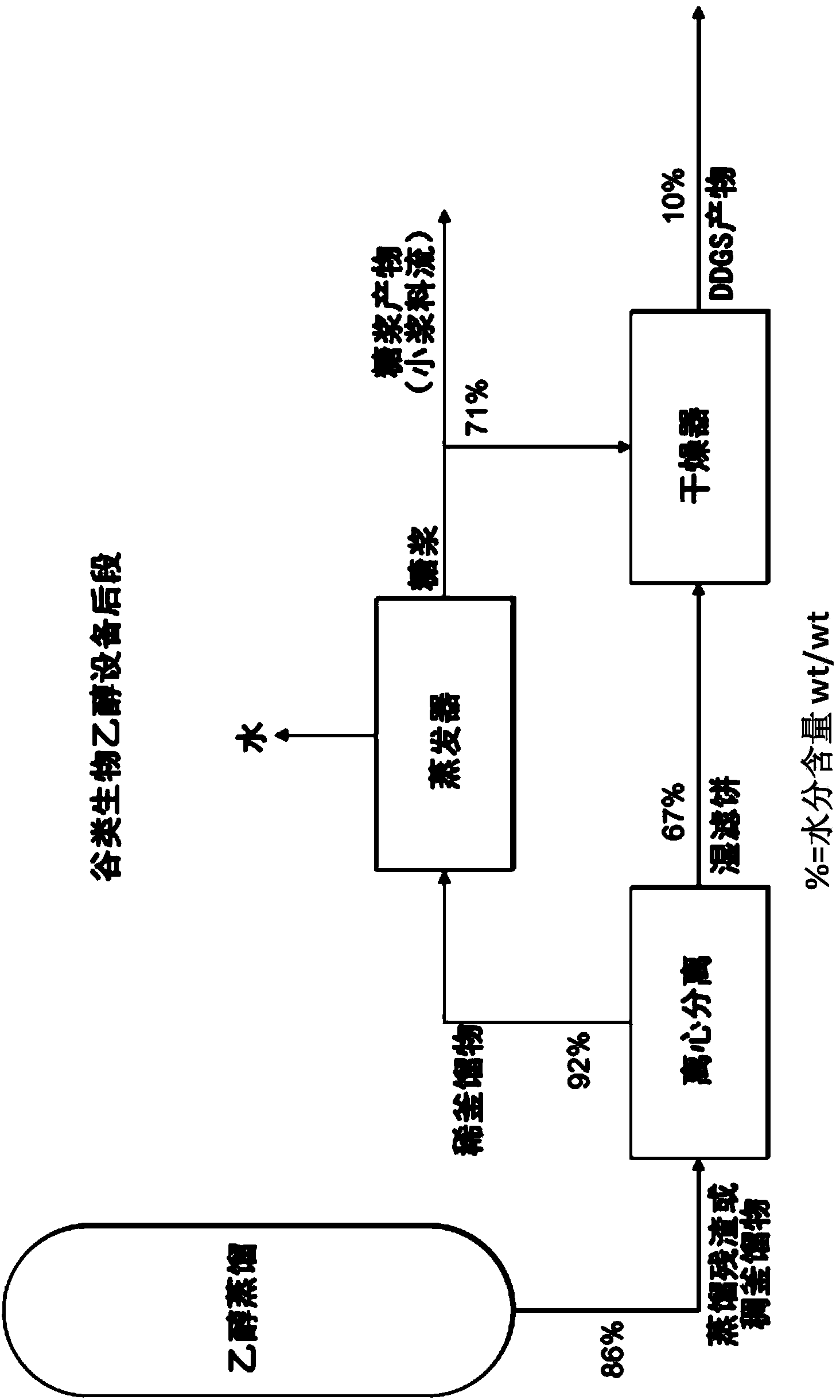

[0063] Thin stillage is obtained through a bioethanol process (Ensus). figure 1 Ensus and the point in the process where thin stillage is produced are shown. The percent moisture content (wt / wt) used for each step of the process is shown. Thin stillage is the semi-solid residue stream of the ethanol process, and it is obtained after removal of the wet cake from the residue. The thin stillage is expected to be free of starch and glucose, and the carbohydrates will be mainly residues of cellulose and hemicellulose. It is also expected that under optimal conditions its hydrolysis will release most of the sugars from these materials.

[0064] Materials and methods

[0065] thin stillage

[0066] Thin stillage is obtained by Ensus from their ethanol plant (see introductory section and figure 1 ).

[0067] Acid hydrolysis of thin stillage

[0068] Add 0.125ml of concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com