Modifier for cement concrete and method for improving performance of cement concrete

A technology of cement concrete and modifier, which is applied in the field of improving the performance of cement concrete. It can solve the problems of poor permeability, reduce the performance of cement or concrete, etc., and achieve the effects of reducing water absorption, inhibiting entry and erosion, and improving flexural resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Mix 20 mL of tetraethyl orthosilicate, 11 mL of water, and 80 mL of ethanol, add acetic acid to adjust the pH of the above solution to 3.8, stir for 1 h, and obtain transparent SiO 2 Sol, that is, modifier.

[0038] Take six identical mortar test blocks with an age of 20 days and a water-cement ratio of 0.6, three of which are not treated as the control group, and the other three as the experimental group, and are treated as follows: soak in the above sol 3 h, take it out.

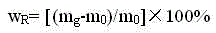

[0039] The test blocks of the experimental group and the control group were tested for absorption rate and mechanical properties, and the calculated data were averaged. The water absorption test results show that the water absorption of the test block modified by the modifier (experimental group) is 67% lower than that of the untreated (control group) after being placed in water for 150 minutes, indicating that the modifier effectively forms a protective layer , can hinder the erosion of external ...

Embodiment 2

[0041] Mix 20 mL tetrabutyl orthosilicate, 6 mL water, and 110 mL ethanol evenly, add oxalic acid to adjust the pH of the above solution to 3.6, stir for 1 h, and obtain transparent SiO 2 Sol, that is, modifier.

[0042] Take six identical mortar test blocks with an age of 30 days and a water-cement ratio of 0.6, three of which are not treated as the control group, and the other three as the experimental group, and are treated as follows: use the above sol for coating Brush, the frequency of brushing is 8 min / time, the time of brushing is 5 h, take it out.

[0043] The test blocks of the experimental group and the control group were tested for absorption rate and mechanical properties, and the calculated data were averaged. The water absorption test results show that the water absorption of the test block modified by the modifier is 55% lower than that of the untreated test block after being placed in water for 150 minutes, indicating that the modifier effectively forms a pro...

Embodiment 3

[0045] Mix 20 mL tetrapropyl orthosilicate, 1.8 mL water, and 150 mL ethanol evenly, add oxalic acid to adjust the pH of the above solution to 3.4, stir for 2 h, and obtain transparent SiO 2 Sol, that is, modifier.

[0046] Take six identical mortar test blocks with an age of 20 days and a water-cement ratio of 0.6, three of which are not treated as the control group, and the other three as the experimental group, and are treated as follows: soak in the above sol 1.5 h, take it out.

[0047] The test blocks of the experimental group and the control group were tested for absorption rate and mechanical properties, and the calculated data were averaged. The water absorption test results show that after 150 minutes in water, the water absorption of the test block modified by the modifier is 57% lower than that of the untreated block, indicating that the modifier effectively forms a protective layer, which can hinder the erosion of external corrosive media . The test results of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com