Method for improving anti-pollution performance of hydrophobic separation membrane by grafting hyperbranched PEG (polyethylene glycol) to surface of hydrophobic separation membrane

A technology of hydrophobic separation membrane and surface grafting, applied in the field of surface modification of separation membrane, can solve the problems of high requirement of reaction conditions, insignificant improvement of effect, difficulty in generating grafting sites on the surface of hydrophobic separation membrane, etc. The effect of chemical grafting, improving anti-pollution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

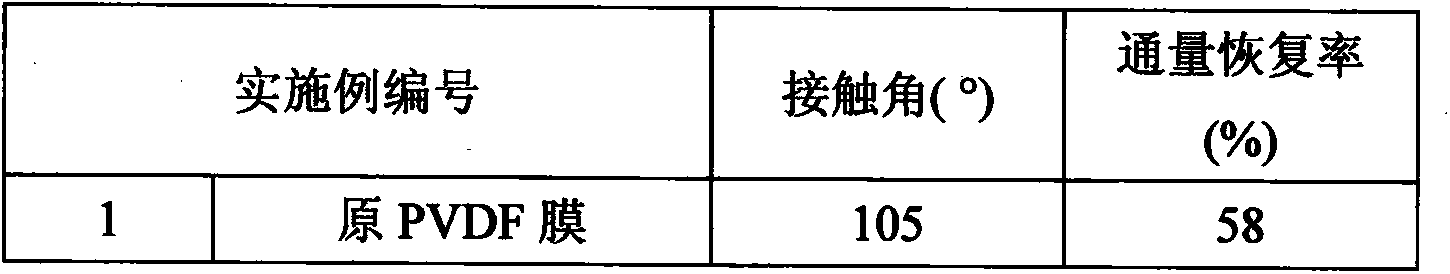

Examples

Embodiment 1

[0022] A method for grafting hyperbranched PEG on the surface of a hydrophobic separation membrane to improve its antifouling performance, the specific steps are:

[0023] Step 1: Cut the cut 10×10cm 2 The PVDF flat film was placed in a cold plasma surface treatment instrument, and plasma discharge treatment was performed for 100s in an oxygen atmosphere with a power of 100W.

[0024] Step 2: Graft hyperbranched PEG on the surface of the film after discharge treatment using the "Grafting from" method. The specific steps of the "Grafting from" are:

[0025] Step 2.1: Soak the membrane in 0.5% TMC n-hexane solution for full reaction for 10 minutes, take it out and quickly soak it in 5% PEG400 dichloromethane solution for full reaction for 10 minutes;

[0026] Step 2.2: Repeat step 2.14 times to obtain a modified PVDF membrane grafted with hyperbranched PEG on the surface based on the directional reaction of the hydroxyl group and the acid chloride bond, and wash it with deioniz...

Embodiment 2

[0028] A method for grafting hyperbranched PEG on the surface of a hydrophobic separation membrane to improve its antifouling performance, the specific steps are:

[0029] Step 1: Cut the cut 10×10cm 2 The PVDF flat film was placed in a cold plasma surface treatment instrument, and plasma discharge treatment was performed for 100s in an oxygen atmosphere with a power of 100W.

[0030] Step 2: Grafting hyperbranched PEG on the surface of the film after discharge treatment using the "Grafting to" method. The specific steps of the "Grafting to" method are:

[0031] Step 2.1: Blend 3.5g of PEG1000 and 1g of TMC in 100ml of dichloromethane solvent to obtain a hyperbranched PEG solution with terminal acid chloride groups;

[0032] Step 2.2: Place the membrane after the discharge treatment in the acid chloride-terminated hyperbranched PEG solution, directly carry out the grafting reaction for 1 hour, and wash it with deionized water for use.

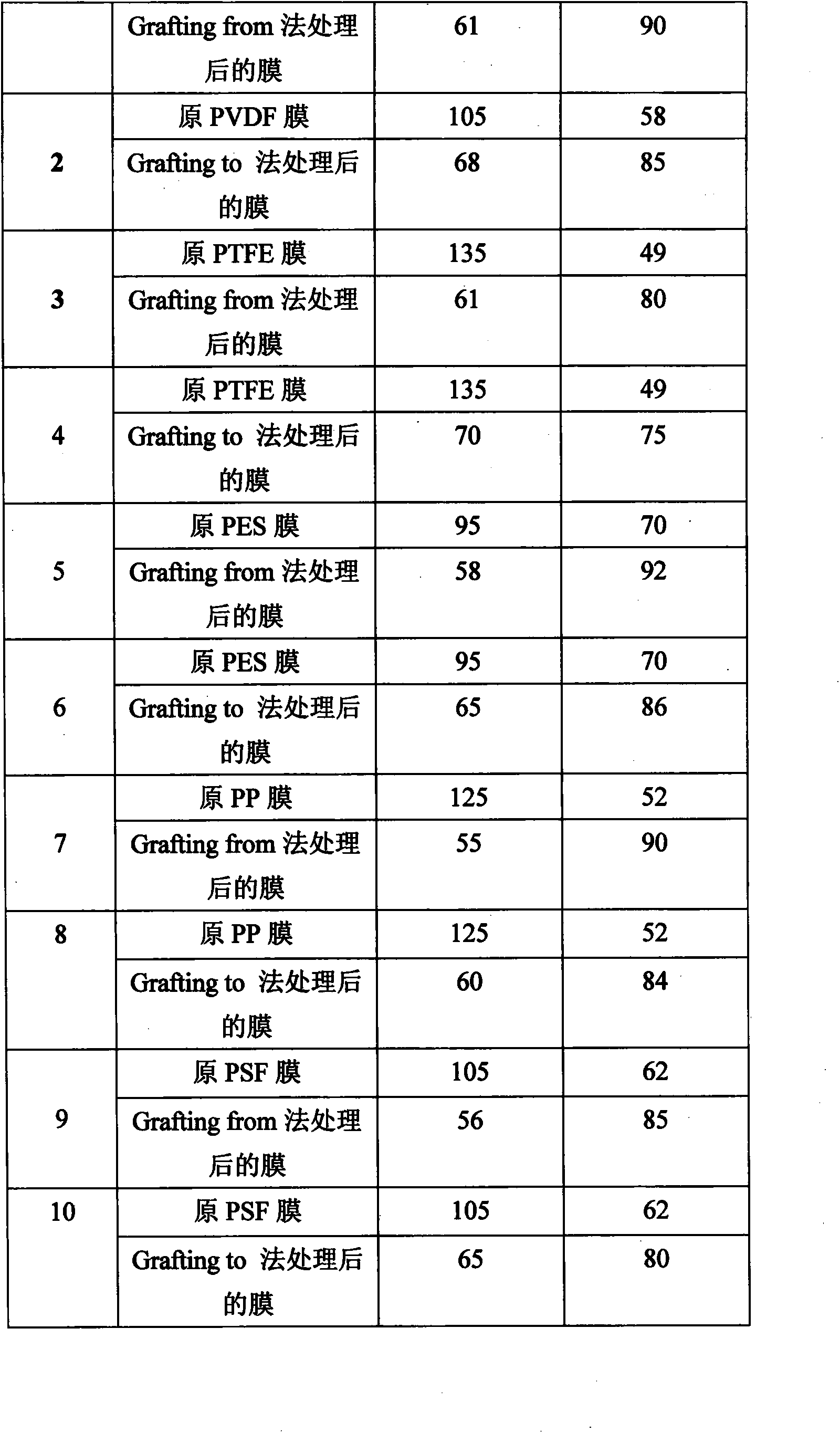

Embodiment 3

[0034] A method for grafting hyperbranched PEG on the surface of a hydrophobic separation membrane to improve its antifouling performance, the specific steps are:

[0035] Step 1: Cut the cut 10×10cm 2 The PTFE flat film was placed in an atmospheric pressure dielectric barrier discharge plasma treatment device, and the plasma discharge treatment was performed for 30s in an air atmosphere with a power of 500W.

[0036] Step 2: Graft hyperbranched PEG on the surface of the film after discharge treatment using the "Grafting from" method. The specific steps of the "Grafting from" are:

[0037] Step 2.1: Soak the membrane in a 1% TMC-hexane solution for a full reaction for 10 minutes, take it out and quickly soak it in a 5% PEG4000 dichloromethane solution for a full reaction for 20 minutes;

[0038] Step 2.2: Repeat step 2.15 times to obtain a modified PVDF membrane grafted with hyperbranched PEG on the surface based on the directional reaction of the hydroxyl group and the acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com