Transition metal phosphide hydrogenation catalyst and preparation method thereof

A technology of hydrogenation catalyst and transition metal, applied in the field of transition metal phosphide hydrogenation catalyst and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

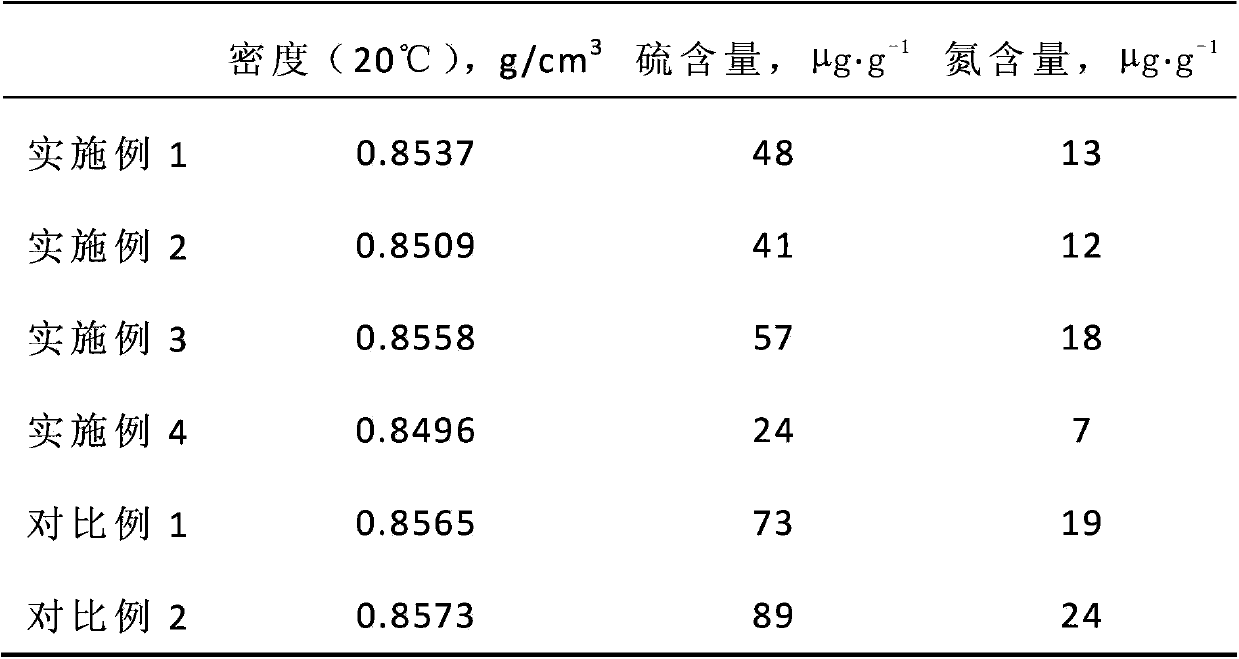

Embodiment 1

[0015] 10.9g of ammonium tungstate (8.4g in terms of WO), 47.1g of nickel nitrate (12.5g in terms of NiO) and 14.6g of ammonium dihydrogen phosphate (in terms of P 2 o 5 9.1 g in total) was dissolved in 54.3 g of deionized water to prepare solution A1. At room temperature, an equal volume of solution A1 was impregnated onto 70 g of the inorganic porous material, dried at room temperature for 12 hours, then dried at 110° C. for 8 hours, and calcined at 530° C. for 6 hours to obtain a transition metal phosphide hydrogenation catalyst precursor. The precursor was heated at room temperature at 30°C / h under N 2 Under the atmosphere, raise the temperature to 250°C, keep the temperature constant for 5 hours, switch to the hydrogen atmosphere, raise the temperature to 550°C at 30°C / h, and then reduce the temperature at constant temperature for 6 hours to obtain a transition metal phosphide hydrogenation catalyst, which is named Cat-A.

Embodiment 2

[0017] 12.9g of ammonium tungstate (9.9g in terms of WO), 41.9g of nickel nitrate (11.1g in terms of NiO) and 14.4g of ammonium dihydrogen phosphate (in terms of P 2 o 5 Total 9.0g) was dissolved in 54.3g deionized water to prepare solution A2. The following steps were the same as in Example 1 to obtain Cat-B.

Embodiment 3

[0019] 20.4g of ammonium tungstate (15.7g in terms of WO), 21.9g of nickel nitrate (5.8g in terms of NiO) and 13.7g of ammonium dihydrogen phosphate (in terms of P 2 o 5 8.5 g in total) was dissolved in 54.3 g of deionized water to prepare solution A3. The following steps were the same as in Example 1 to obtain Cat-C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com