Hydrodenitrification catalyst carrier as well as preparation method and application thereof

A catalyst carrier, hydrodenitrogenation technology, applied in catalyst carrier, chemical instrument and method, metal/metal oxide/metal hydroxide catalyst, etc. Weak acidity and other problems, achieve highly ordered mesoporous pore structure, improve hydrogenation catalytic activity, and overcome the effect of strong interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

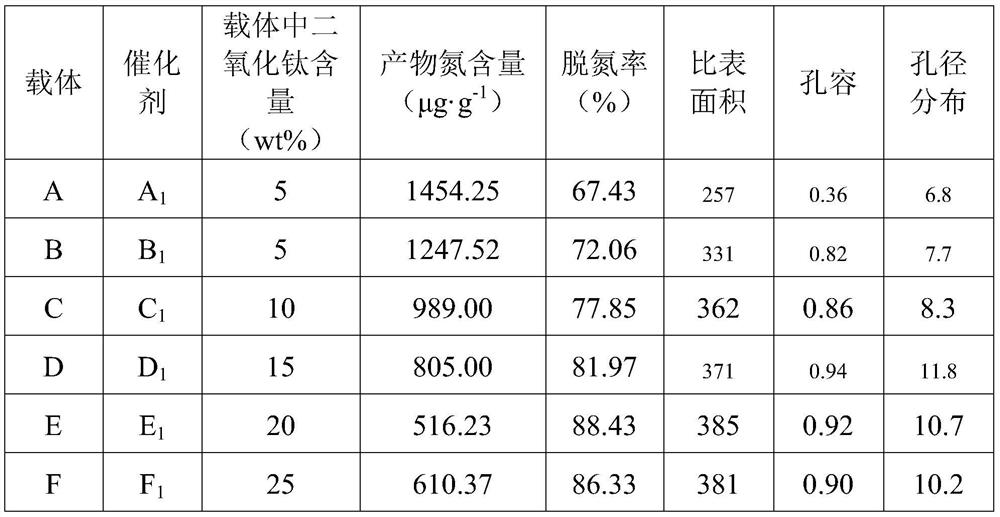

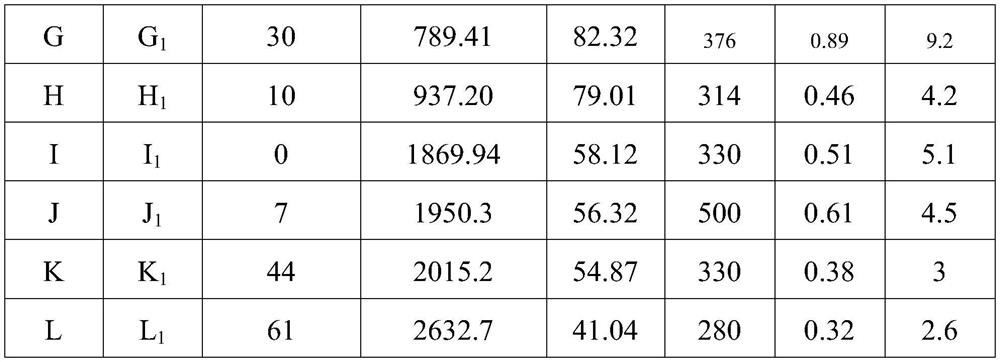

Embodiment 1

[0047] Weigh 4.085g of aluminum isopropoxide, add 20mL of absolute ethanol, 3.2mL of nitric acid, and 1.4mL of deionized water in sequence, and mix and stir for 4 hours at room temperature to obtain solution 1; at the same time, weigh 2g of P123 template and dissolve in 20mL of water and ethanol, stirred at room temperature for 2 hours to obtain solution 2; add solution 1 dropwise to solution 2, and continue to stir at room temperature for 4 hours to obtain solution C; the obtained solution C was placed in an oven at 70°C, and the solvent was automatically Evaporate until the sample is dry, and then bake at 550°C (the same heating rate is 2°C / min) for 4h. Tablets were pressed on a tablet machine (15Mpa, 15min), and sieved into 20-40 mesh particles in a Taylor sieve to obtain carrier A.

Embodiment 2

[0049] Weigh 3.819g of aluminum isopropoxide, add 20mL of absolute ethanol, 3.2mL of nitric acid, and 1.4mL of deionized water in sequence, and mix and stir for 4 hours at room temperature to obtain solution 1; at the same time, weigh 2g of P123 template and dissolve in 20mL of Water and ethanol, stirred at room temperature for 2 hours to obtain solution 2; add solution 1 dropwise to solution 2, after mixing evenly, weigh 0.445g of isopropyl titanate, and add dropwise to solution C, room temperature Stirring was continued for 4 hours at low temperature to obtain solution D; the obtained solution D was placed in an oven at 70°C, the solvent evaporated automatically until the sample was dry, and then roasted at 550°C (the same heating rate was 2°C / min) for 4 hours. The above prepared TiO 2 The titanium-aluminum composite oxide with a content of 5wt% is then compressed on a tablet machine (15Mpa, 15min), and sieved into 20-40 mesh particles in a Taylor sieve to obtain the carrier...

Embodiment 3

[0051] Weigh 3.574g of aluminum isopropoxide, add 20mL of absolute ethanol, 3.2mL of nitric acid, and 1.4mL of deionized water in sequence, and mix and stir for 4 hours at room temperature to obtain solution 1; at the same time, weigh 2g of P123 template and dissolve in 20mL of Water and ethanol were stirred at room temperature for 2 hours to obtain solution 2; solution 1 was added dropwise to solution 2, and after mixing evenly, 0.849 g of isopropyl titanate was weighed and added dropwise to solution C, at room temperature Stirring was continued for 4 hours at low temperature to obtain solution D; the obtained solution D was placed in an oven at 70°C, the solvent evaporated automatically until the sample was dry, and then roasted at 550°C (the same heating rate was 2°C / min) for 4 hours. The above prepared TiO 2 The titanium-aluminum composite oxide with a content of 10wt% was compressed on a tablet machine (15Mpa, 15min), and sieved into 20-40 mesh particles in a Taylor sieve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com