Electric heating floor blank based on CLT (Cross-Laminated Timber) board and manufacturing method thereof

A manufacturing method and floor blank technology, which are applied in the field of floor manufacturing, can solve the problems of aging and degumming of the adhesive layer on the surface of the film, unstable dimensions of the electric heating floor, cracking of the heating film, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] a. Select the fir CLT board with a three-layer structure, the specification is length × width × thickness = 2440 × 1200 × 15mm, and mill out the grooves of full length along the width direction of the board at intervals of 45mm, the groove width is 17mm, and the depth is 0.5mm;

[0022] b. Cut the heating film with a thickness of 0.4mm into a strip sheet with a length of 2400mm and a width of 15mm and place it in the groove;

[0023] c. Choose a 3mm thick oak wood sawn thin board, apply two-component polyurethane adhesive on one side, and the glue amount is 100g / m2 2 , covered on the surface of the CLT plate embedded with heating film, pressurized and glued into a whole at room temperature, the pressurized pressure is 3MPa, and the pressurized time is 2h;

[0024] d. After aging for 24 hours, saw the CLT board into floor blanks with a length of 1200mm and a width of 200mm.

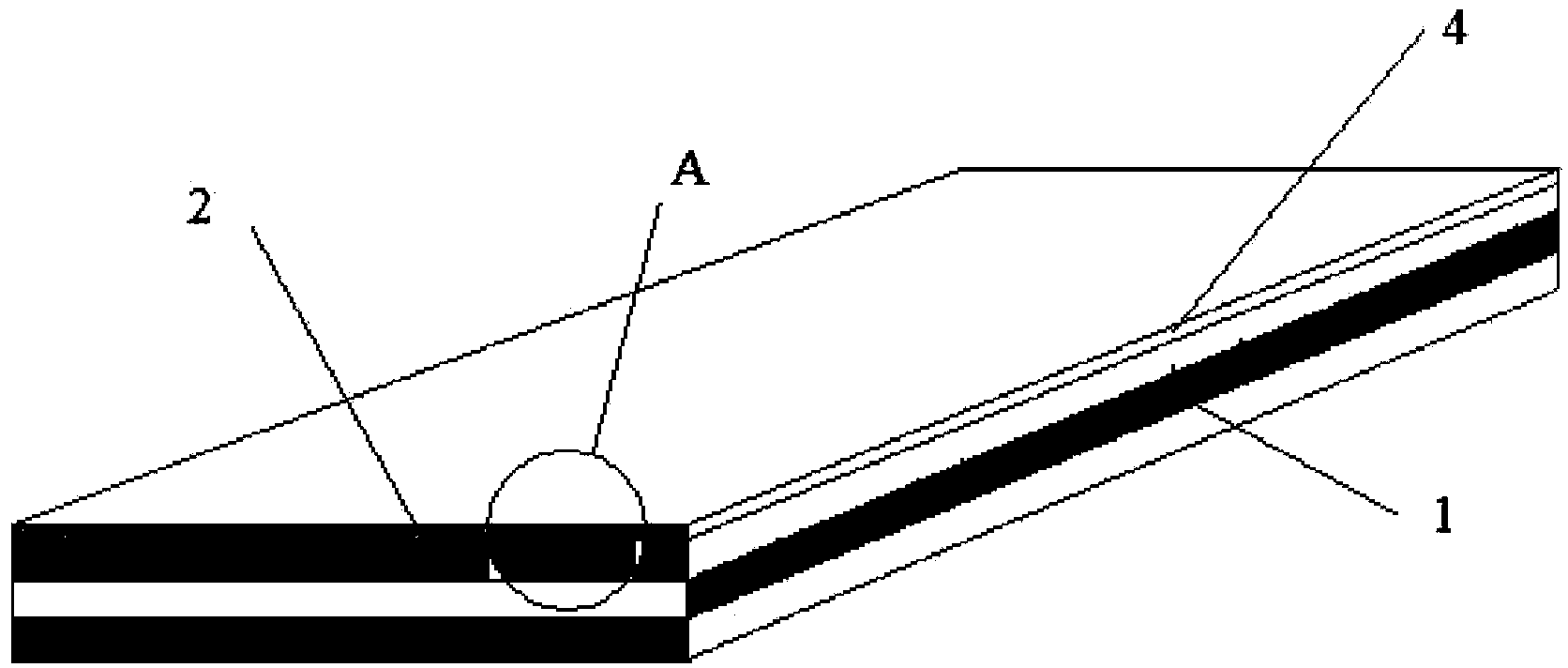

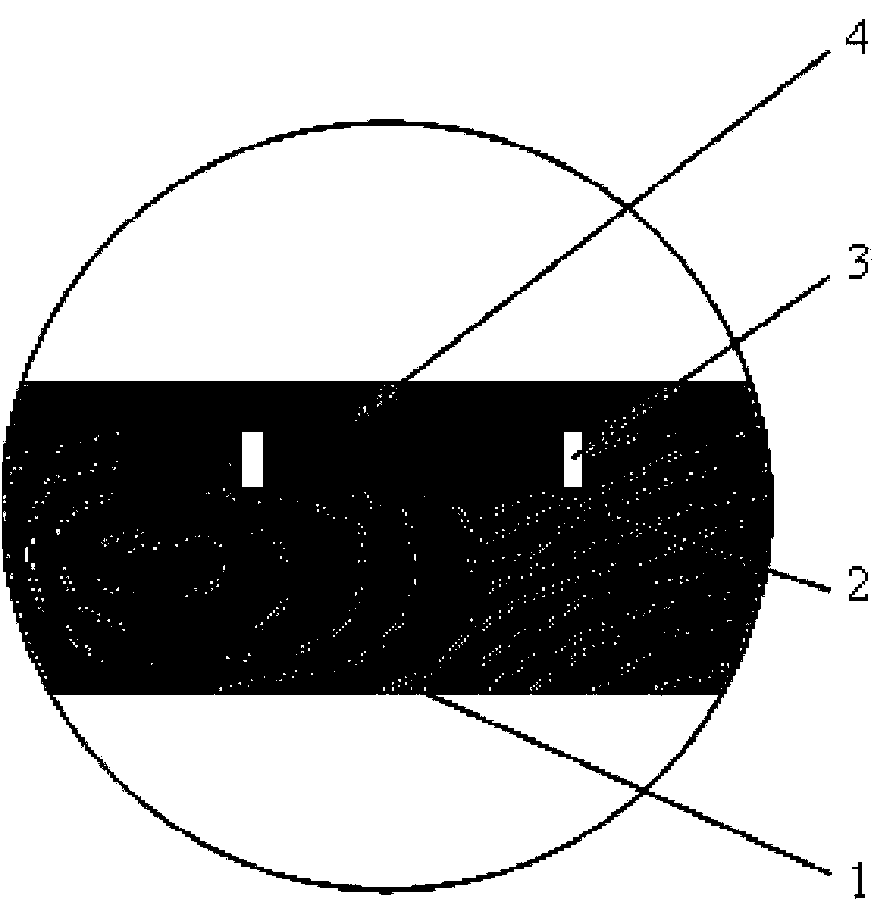

[0025] Prepared floor blanks such as Figure 1-2 As shown, the electric heating floor blank in...

Embodiment 2

[0028] In this embodiment, the difference from Example 1 is: on the 3mm thick oak veneer, the urea-formaldehyde resin adhesive is coated on one side, and the amount of glue applied is 150g / m 2 , covered on the surface of the CLT plate embedded with the heat-generating film, hot-pressed and glued together as a whole, the hot-pressing pressure is 1.5 MPa, the hot-pressing temperature is 110°C, and the hot-pressing time is 6 minutes.

Embodiment 3

[0030] In this embodiment, the difference from Embodiment 1 is: select the Chinese fir CLT board with three-layer structure, the specification is length×width×thickness=2440×1200×18mm, and choose 1.5mm thick maple veneer as the precious wood surface.

[0031] In this embodiment, the thermal conductivity was measured, and it can reach about 40° C. within 2 hours and keep the temperature constant. After being treated for 48±0.25 hours at a temperature of 50±2°C, the average shrinkage rate of the length is 0.14%, the average shrinkage rate of the width is 0.18%, the average shrinkage rate of the thickness is 2.68%, and the average shrinkage rate of the volume is 2.98%; after treatment for 48±0.25h under the conditions of temperature 40±2℃ and relative humidity 85%±5%, the average wet expansion rate of the length is 0.20%, the average wet expansion rate of the width is 0.18%, and the average wet expansion rate of the thickness The rate is 4.23%, and the volume average wet expansio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| warpage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com