Modification method for nano calcium peroxide with controllable particle size

A calcium peroxide and nanotechnology, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as easy agglomeration, large particle size, and easy blockage of transmission pipes, and achieve high The effect of adsorption performance, large specific surface area, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Accurately weigh 60g of polyvinylpyrrolidone (PVP), dissolve it in 120mL of deionized water, ultrasonicate and stir until it is completely dissolved. Weigh 6g of calcium hydroxide and add it into the dispersant solution, and stir it mechanically for 20 minutes at room temperature to make it fully mixed to form a reaction bottom liquid.

[0036](2) Add 63.46mL of 30% hydrogen peroxide into the self-made slow titration device, control the flow rate at 20-30 drops / min, slowly drop into the bottom solution, and react at room temperature with constant stirring. Continue to react for 15 minutes after the dropwise addition is completed, so that the calcium salt and hydrogen peroxide fully react to form stable nano-scale calcium peroxide particles.

[0037] (3) The formed precipitate was centrifuged, and the product was washed with deionized water and absolute ethanol, and dried under vacuum at 30°C for 24 hours to obtain nanoscale calcium peroxide powder.

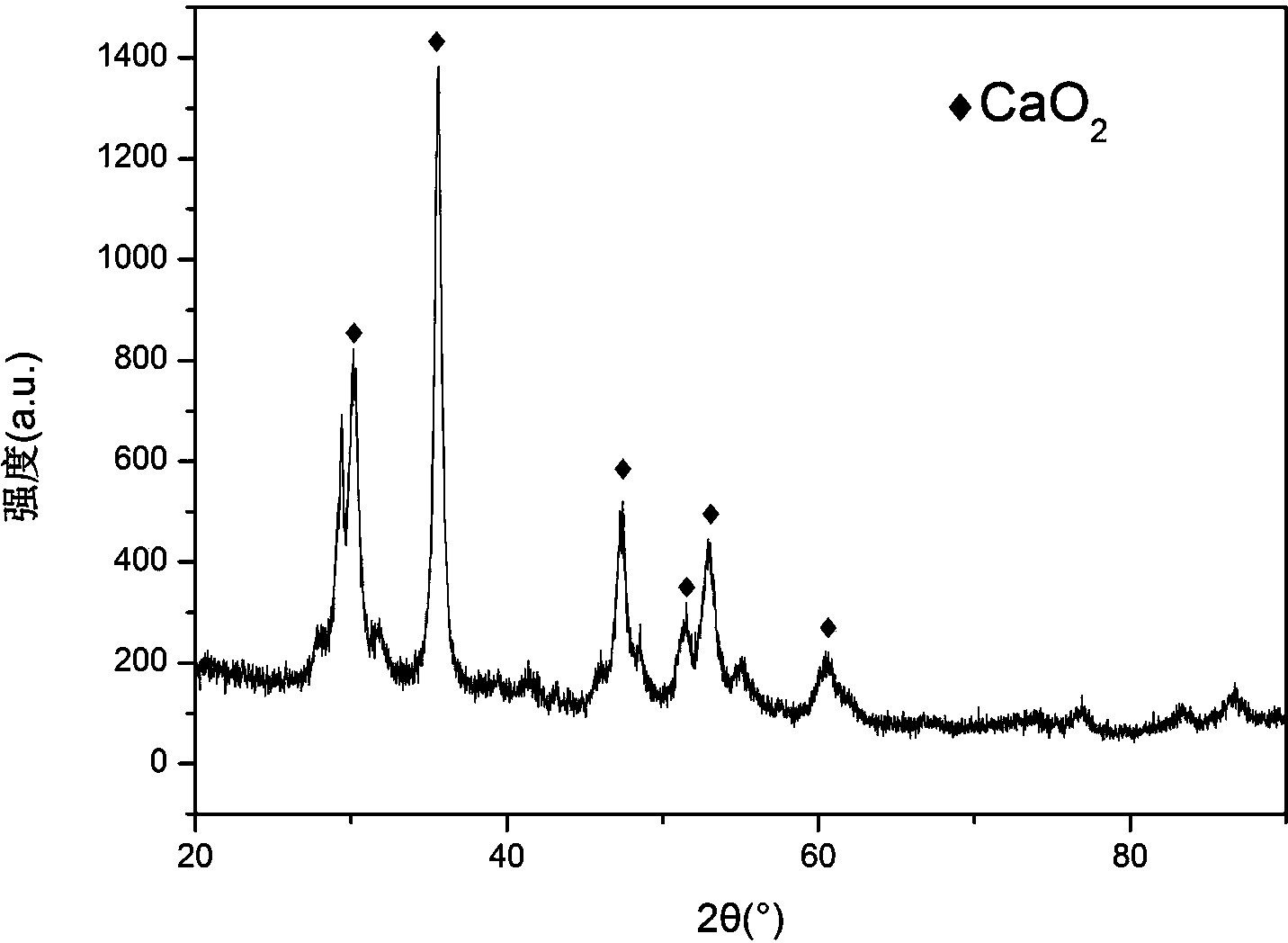

[0038] figure...

Embodiment 2

[0040] (1) Accurately weigh 24g of PVP, dissolve it in 120mL deionized water, ultrasonicate and stir until it is completely dissolved. Weigh 6g of calcium hydroxide and add it into the dispersant solution, and stir it mechanically for 20 minutes at room temperature to make it fully mixed to form a reaction bottom liquid.

[0041] (2) Add 63.46mL of 30% hydrogen peroxide into the self-made slow titration device, control the flow rate at 20-30 drops / min, slowly drop into the bottom solution, and react at room temperature with constant stirring. Continue to react for 15 minutes after the dropwise addition is completed, so that the calcium salt and hydrogen peroxide fully react to form stable nano-scale calcium peroxide particles.

[0042] (3) The formed precipitate was centrifuged, and the product was washed with deionized water and absolute ethanol, and dried under vacuum at 30°C for 24 hours to obtain nanoscale calcium peroxide powder.

[0043] The synthesized sample is charac...

Embodiment 3

[0045] (1) Accurately weigh 12g of PVP, dissolve it in 120mL of deionized water, ultrasonicate and stir until it is completely dissolved. Weigh 6g of calcium hydroxide and add it into the dispersant solution, and stir it mechanically for 20 minutes at room temperature to make it fully mixed to form a reaction bottom liquid.

[0046] (2) Add 63.46mL of 30% hydrogen peroxide into the self-made slow titration device, control the flow rate at 20-30 drops / min, slowly drop into the bottom solution, and react at room temperature with constant stirring. Continue to react for 15 minutes after the dropwise addition is completed, so that the calcium salt and hydrogen peroxide fully react to form stable nano-scale calcium peroxide particles.

[0047] (3) The formed precipitate was centrifuged, and the product was washed with deionized water and absolute ethanol, and dried under vacuum at 30°C for 24 hours to obtain nanoscale calcium peroxide powder.

[0048] The synthesized sample is cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com