Quantum-dot nanometer particle containing hydrophobic interlayer and preparation method thereof

A nanoparticle and quantum dot technology, which is applied in the field of quantum dot nanoparticles with high fluorescence quantum yield and its preparation, can solve the problems of destroying quantum dot luminous efficiency, reducing fluorescence quantum efficiency, and difficult to stop quenching factors, etc., to achieve excellent biological Compatibility and colloidal stability, the effect of improving fluorescence stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

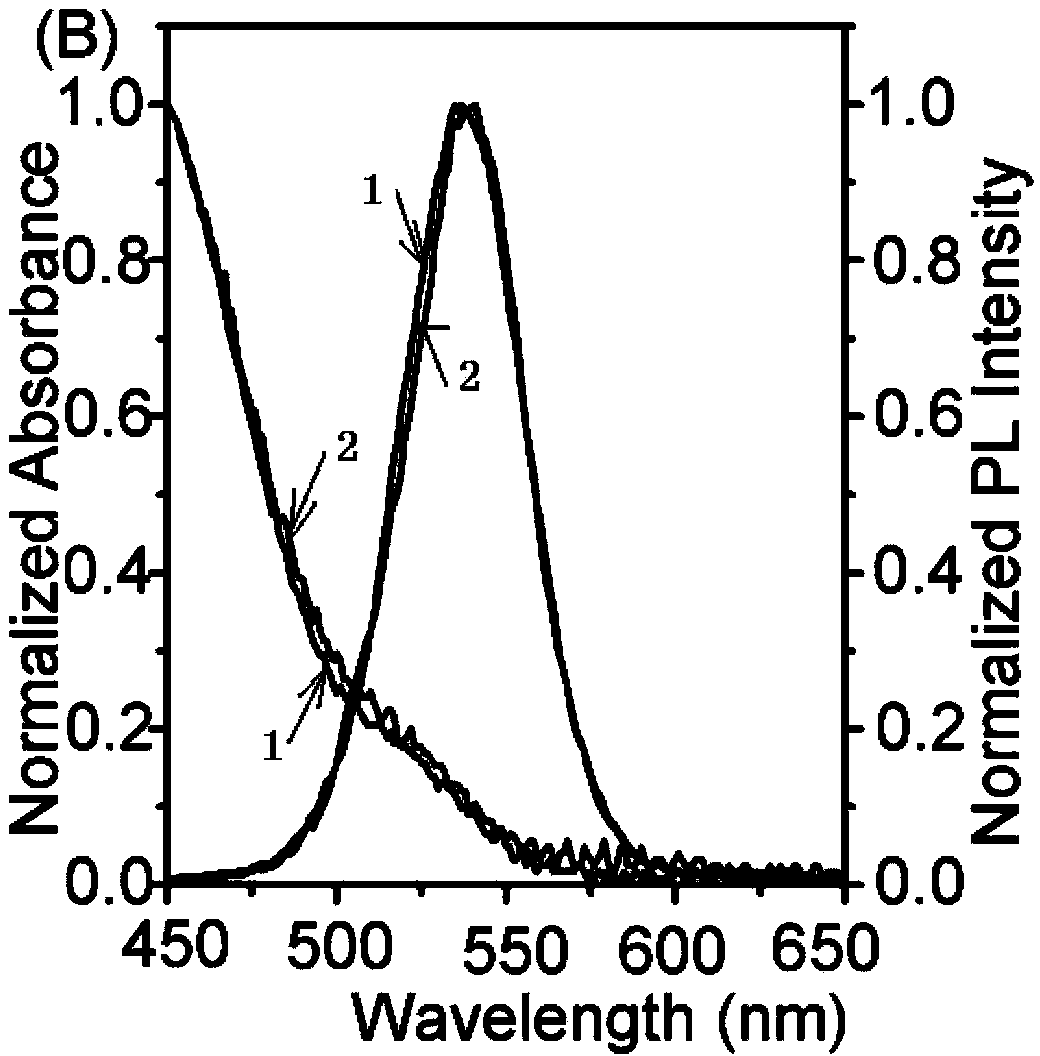

[0050] Embodiment 1 contains the high fluorescence quantum yield CdSeS / ZnS of hydrophobic interlayer (λ max 545nm) preparation of quantum dots

[0051] 1. CdSeS / ZnS (λ max 545nm) synthesis of quantum dots

[0052] Put 256.8mg of CdO (2mmol), 2.5ml of oleic acid (OA) and 20ml of tri-n-octylamine (TOA) in a three-necked flask, and heat to 300°C under the protection of argon to obtain a colorless solution. When the temperature was stabilized at 300°C, S (3.0mL, 64.14mg mL -1 ) and Se (1.0mL, 15.79mg mL -1 ) TOP mixed solution was quickly added to CdO / OA / TOA, stirred vigorously for 1 minute. The temperature was lowered to 240°C, and the stock solutions of ZnO (ZnO: 40.7mg in1.0mLOA) and S (16.0mg in1.0mL TOP) prepared in advance were mixed and injected rapidly, and reacted for 1 minute. The temperature was lowered to room temperature, poured into ethanol, washed three times with ethanol, and dried to obtain CdSeS / ZnS (λ max 545nm) quantum dots.

[0053] 2. Preparation of hi...

Embodiment 2

[0062] Embodiment 2 contains the high fluorescence quantum yield CdSeS / ZnS of hydrophobic interlayer (λ max 510nm) preparation of quantum dots

[0063] 1. CdSeS / ZnS (λ max 510nm) synthesis of quantum dots

[0064] Put 256.8mg of CdO (2mmol), 2.5ml of oleic acid (OA) and 20ml of tri-n-octylamine (TOA) in a three-necked flask, and heat to 300°C under the protection of argon to obtain a colorless solution. When the temperature was stabilized at 300°C, S (3.0mL, 64.14mg mL -1 ) and Se (0.1mL, 15.79mg mL -1 ) TOP mixed solution was quickly added to CdO / OA / TOA, stirred vigorously for 1 minute. The temperature was lowered to 240°C, and the stock solutions of ZnO (ZnO: 40.7mg in1.0mLOA) and S (16.0mg in1.0mL TOP) prepared in advance were mixed and injected rapidly, and reacted for 1 minute. The temperature was lowered to room temperature, poured into ethanol, washed three times with ethanol, and dried to obtain CdSeS / ZnS (λ max 545nm) quantum dots.

[0065] 2. Preparation of hi...

Embodiment 3

[0071] Embodiment 3 contains the high fluorescence quantum yield CdSeS / ZnS of hydrophobic interlayer (λmax 535nm) preparation of quantum dots

[0072] 1. CdSeS / ZnS (λ max 535nm) synthesis of quantum dots

[0073] Put 256.8mg of CdO (2mmol), 2.5ml of oleic acid (OA) and 20ml of tri-n-octylamine (TOA) in a three-necked flask, and heat to 300°C under the protection of argon to obtain a colorless solution. When the temperature was stabilized at 300°C, S (3.0mL, 64.14mg mL -1 ) and Se (0.6mL, 15.79mg mL -1 ) TOP mixed solution was quickly added to CdO / OA / TOA, stirred vigorously for 1 minute. The temperature was lowered to 240°C, and the stock solutions of ZnO (ZnO: 40.7mg in1.0mLOA) and S (16.0mg in1.0mL TOP) prepared in advance were mixed and injected rapidly, and reacted for 1 minute. The temperature was lowered to room temperature, poured into ethanol, washed three times with ethanol, and dried to obtain CdSeS / ZnS (λ max 545nm) quantum dots.

[0074] 2. Preparation of high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com