Method for preparing highly effective green light rare earth compound film

A technology of rare earth compounds and compounds, applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of restricting the assembly of functional systems and related performance research, lack of mature preparation methods, and unproposed common film forming technology, so as to improve the luminous intensity And the effect of luminescence stability, improvement of fluorescence stability, and good fluorescence stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1. The preparation of high-efficiency green light rare earth compound film, the steps are as follows:

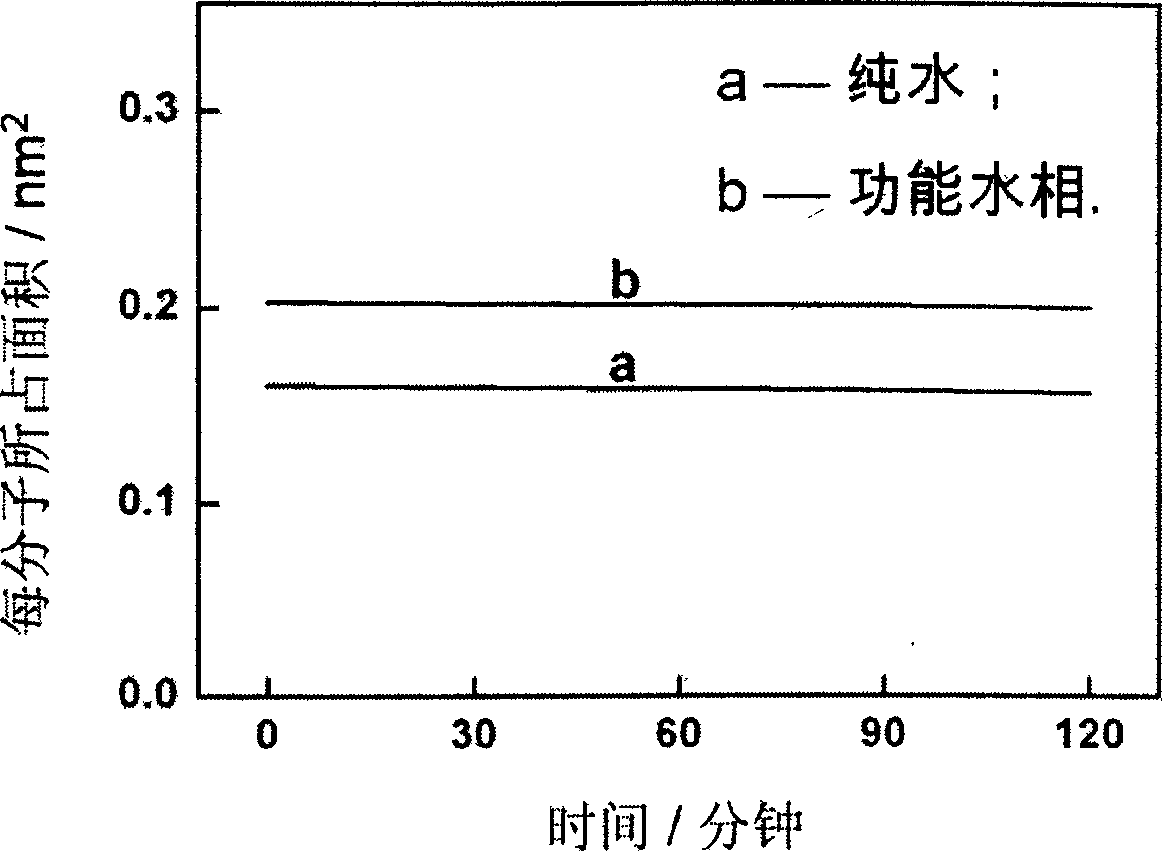

[0039] (1) Preparation of rare earth terbium (III) compound Tb(acac) 3 Phen: first take 1.25mmol terbium oxide (Tb 4 o7 ) brown powder, add 1M dilute hydrochloric acid at 60°C, then add H 2 o 2 , rapid stirring to drive away a large number of bubbles, as the reaction continues, the speed of bubble generation slows down, the solution changes from a brown suspension to a colorless clear solution, continue to heat and stir until the system is nearly dry, and then add a small amount of triple distilled water to obtain TbCl 3 Solution (solution a), 15.0mmol acac was dissolved in 95% ethanol to obtain solution b, 5.0mmol Phen was dissolved in 95% ethanol to obtain solution c, 15.0mmol NaOH was dissolved in triple distilled water to obtain solution d; solution a, Add solution c and solution d dropwise to solution b, reflux under stirring for 1.5 hours to fully ...

Embodiment 2

[0044] Embodiment 2. The preparation of high-efficiency green light rare earth compound film, the steps are as follows:

[0045] (1) Preparation of rare earth terbium (III) compound Tb(acac) with reference to the first (1) step method of Example 1 3 Phen; The gas-liquid two-dimensional surface monolayer film Tb(acac) is prepared with reference to the first (2) step method of Example 1 3 Phen / AA(2 / 1); choose hydrophobic solid substrate, constant surface pressure 25mN m -1 , film lifting speed 10.0mm·min -1 , after preparing two layers of film, the residence time in the air is 360 seconds, and the ultra-thin film of rare earth terbium (III) compound is transferred and deposited on the gas-liquid two-dimensional surface;

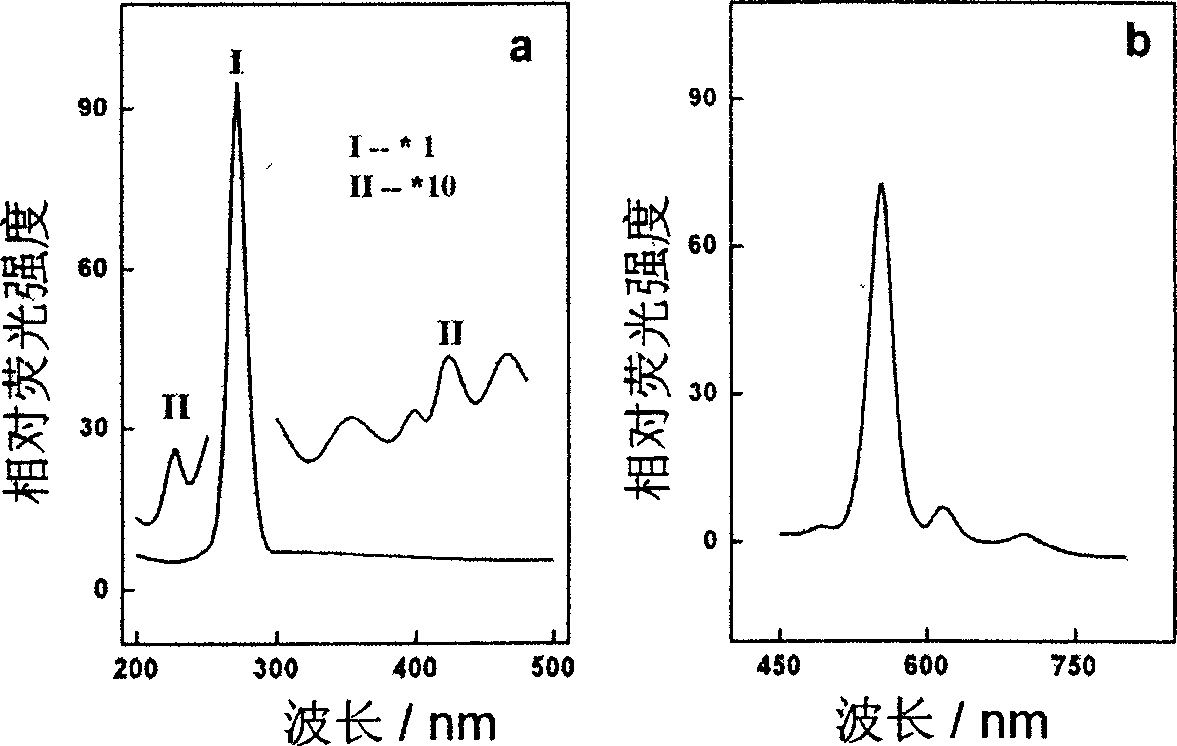

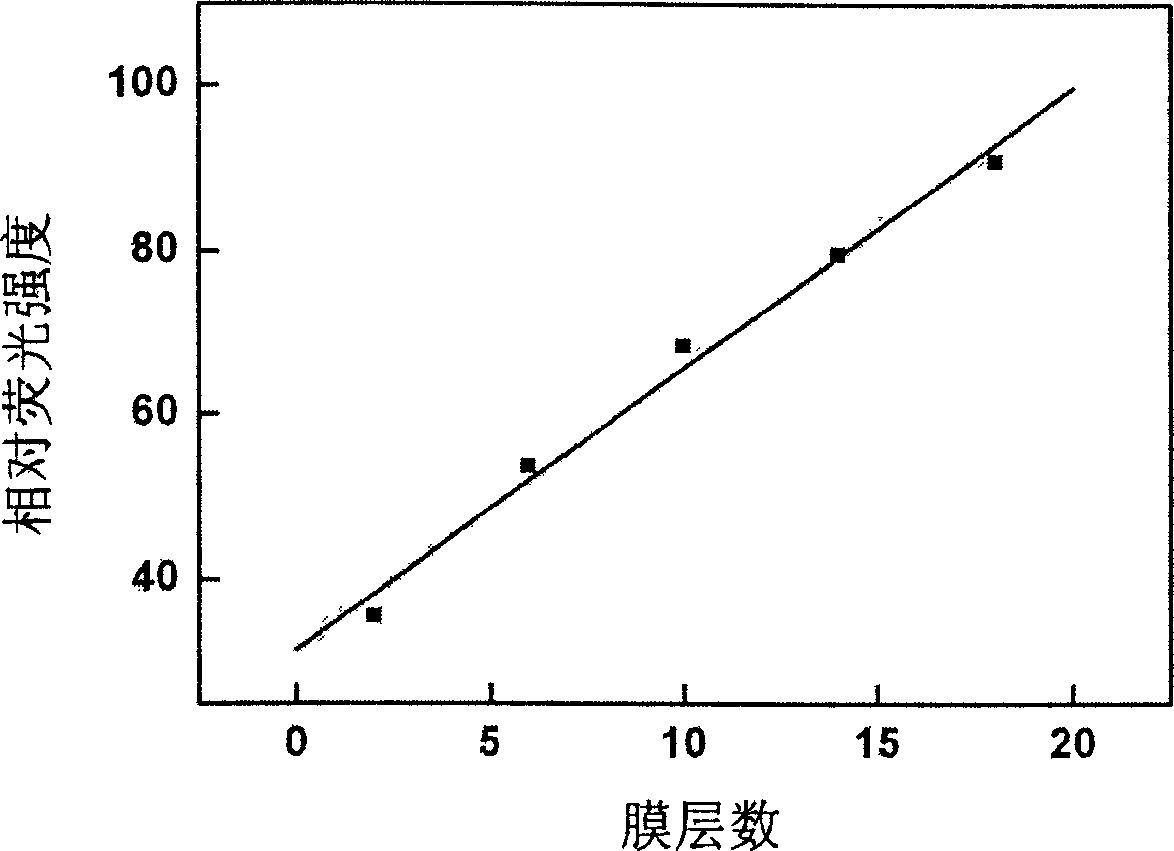

[0046] (2) In the steady-state fluorescence spectrum of LB film, the excitation peaks are located at 230.0, 270.0, 300.0, 355.0, 430.0, 470.0nm, and the emission peaks are located at 488.5, 545.0, 582.5, 617.0, 644.0, 664.0, 674.0nm; the fluorescence emission...

Embodiment 3

[0047] Embodiment 3. The preparation of high-efficiency green light rare earth compound film, the steps are as follows:

[0048] (1) Preparation of rare earth terbium (III) compound Tb(acac) with reference to the first (1) step method of Example 1 3 Phen; The gas-liquid two-dimensional surface monolayer film Tb(acac) is prepared with reference to the first (2) step method of Example 1 3 Phen / AA(1 / 2); choose hydrophobic solid substrate, constant surface pressure 25mN m -1 , film lifting speed 15.0mm·min -1 , after preparing two layers of film, the residence time in the air is 360 seconds, and the ultra-thin film of rare earth terbium (III) compound is transferred and deposited on the gas-liquid two-dimensional surface;

[0049] (2) In the steady-state fluorescence spectrum of LB film, the excitation peaks are located at 230.0, 270.0, 300.0, 355.0, 430.0, 470.0nm, and the emission peaks are located at 488.5, 545.0, 582.5, 617.0, 644.0, 664.0, 674.0nm; the fluorescence emission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com