Chemical spring surface deburring process

A deburring and crafting technology, which is applied in chemical instruments and methods, metal material coating technology, cleaning methods using liquids, etc., to achieve ideal results, save labor, and improve economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

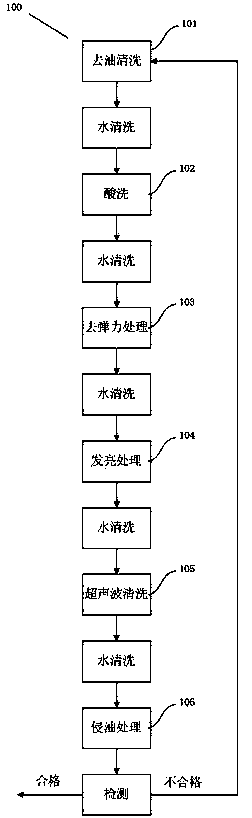

Image

Examples

Embodiment 1-3

[0031] Embodiment 1-3: Ordinary water-75%; Hydrogen peroxide-5%; NH 4 HF 2 -20%.

[0032] 104. Brightening treatment, use brightening treatment liquid to treat the surface of the spring to make the surface of the spring bright, and at the same time eliminate the burrs and impurities on the surface of the spring and remove the elastic force. The brightening treatment solution contains 80% of ordinary water, 15% of hydrogen peroxide and 5% of ammonium bifluoride in terms of mass percentage, and the time for the spring to be brightened at normal temperature and pressure is 20-30 seconds.

[0033] 105. Ultrasonic cleaning, using ultrasonic cleaning equipment in the ultrasonic cleaning solution to clean the surface of the spring to remove iron filings on the surface of the spring;

[0034] 106. Invasion oil treatment, the spring is immersed in the antirust liquid to carry out antirust treatment on its surface, and the antirust liquid contains 5% water-soluble antirust oil and 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com