A kind of quasi-single crystal silicon ingot growth method

A growth method and technology of quasi-single crystal silicon, applied in the directions of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of low cell efficiency, no obvious advantages, and reduced utilization rate of quasi-single crystal ingots, etc. Achieve the effect of low dislocation rate, no crucible contact pollution, and high single crystal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

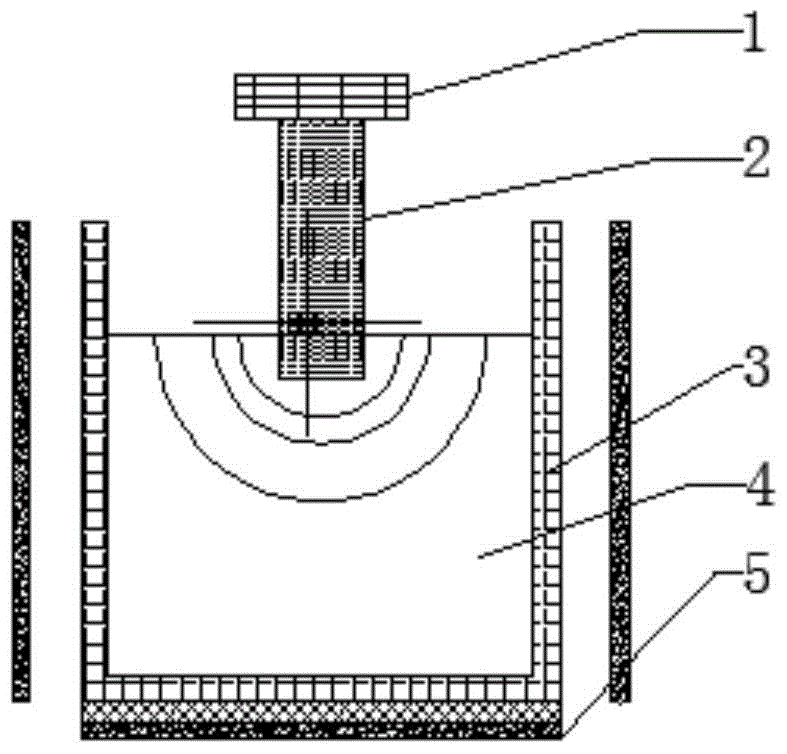

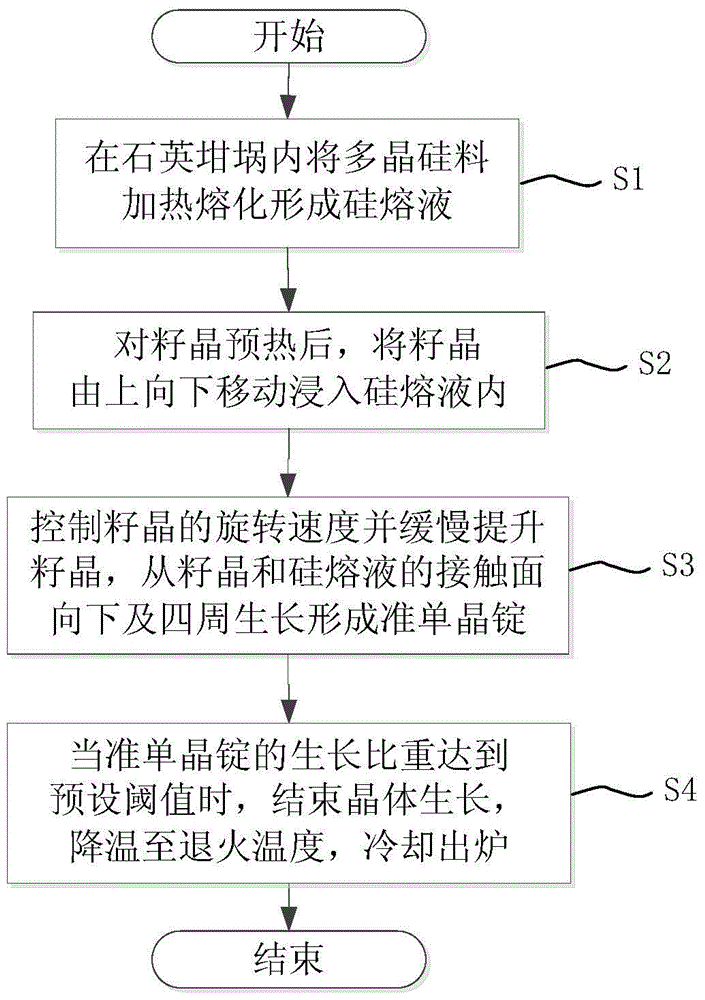

[0021] figure 1 A schematic structural view of the quasi-single crystal silicon ingot furnace used in the present invention; figure 2 It is a schematic diagram of the growth control process of the quasi-single crystal silicon ingot of the present invention.

[0022] See figure 1 and figure 2 , the quasi-single crystal silicon ingot growth method provided by the present invention, the seed crystal 2 with the cooler 1 is immersed in the silicon melt from the top, and the quasi-single crystal growth method is carried out. The heat is mainly taken away by the seed crystal 2 with the cooler 1 and the inert gas flow; the seed crystal with the cooler is connected with a power mechanism, which can realize the rotation and lifting of the seed crystal. The polysilicon material is put into a quartz crucible 3 with a silicon nitride coating for melting, and i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| crystal orientation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com