High precision nanometer clearance detection structure and method on basis of surface plasma resonance

A surface plasmon and nano-gap technology, applied in measuring devices, instruments, optical devices, etc., can solve the problems of low measurement accuracy and difficulty in realizing absolute measurement of nano-scale gaps, and achieve high-precision measurement, simple structure, Easy to Integrate Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: The principle of the present invention and the sensing characteristics under specific parameters are analyzed in detail.

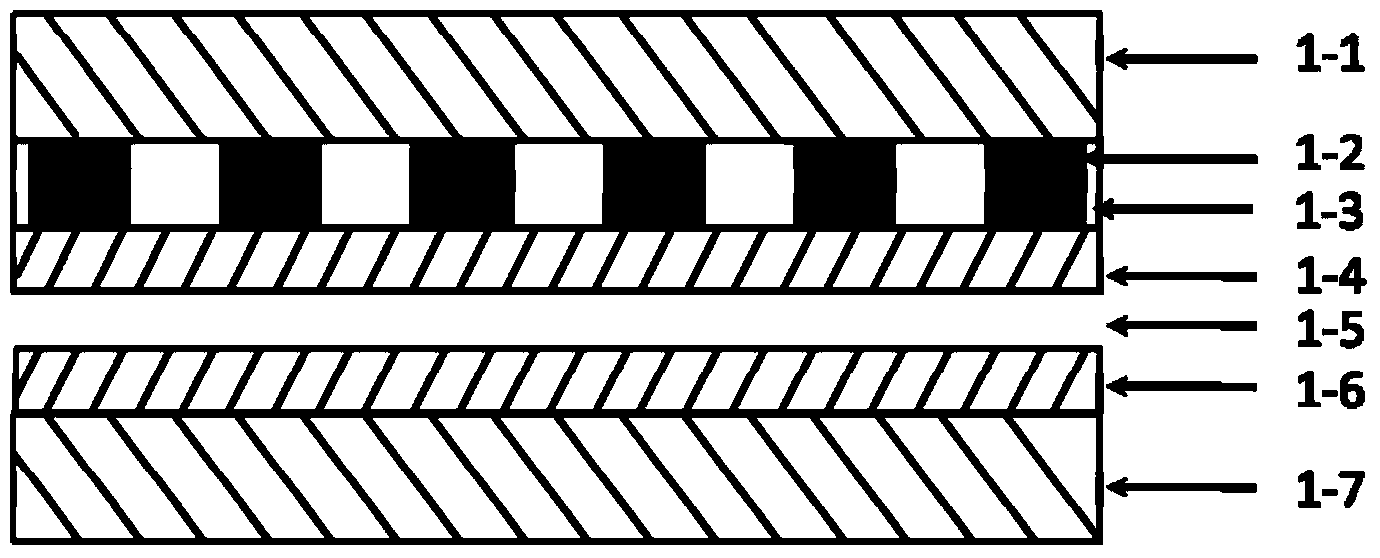

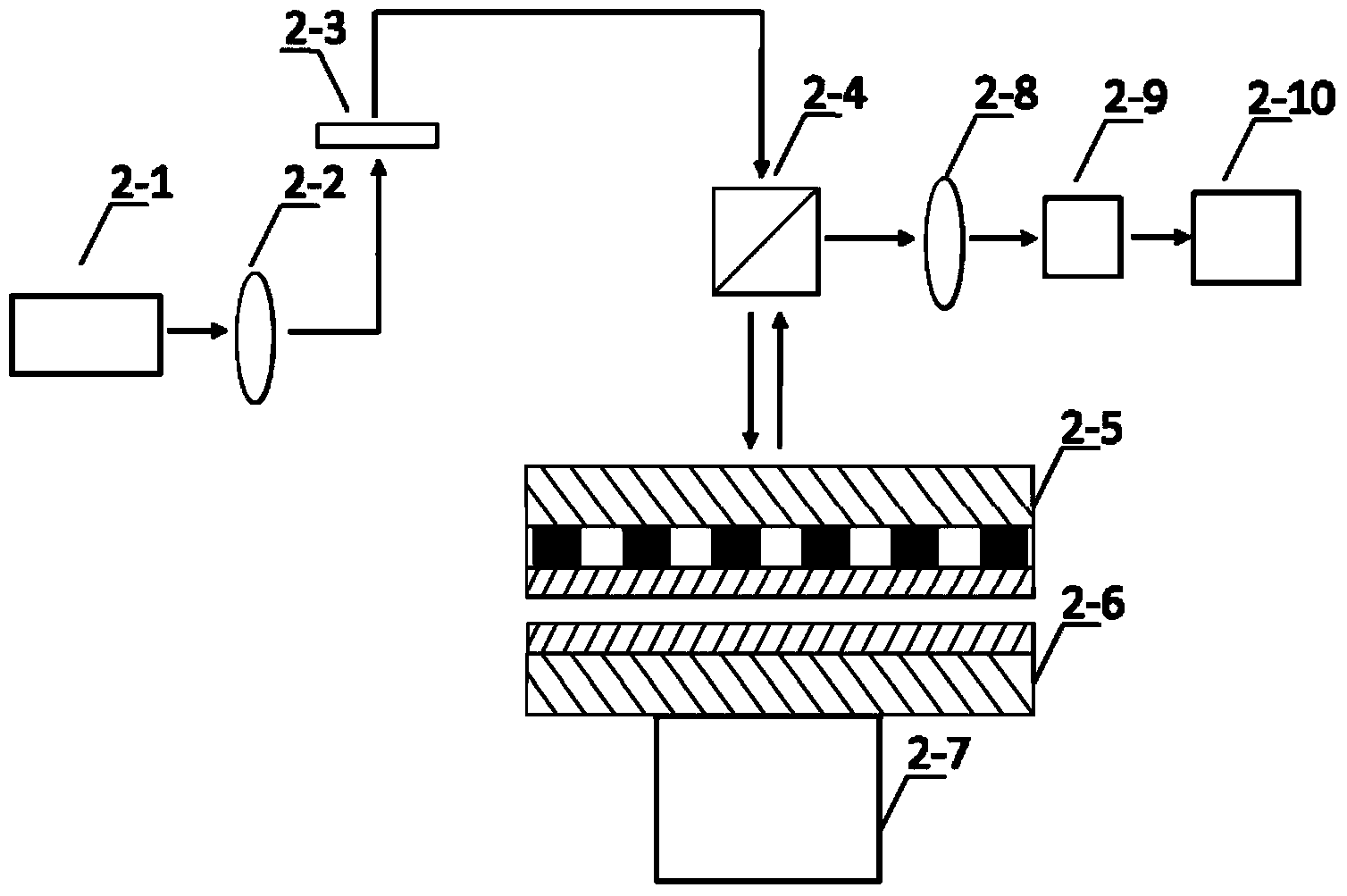

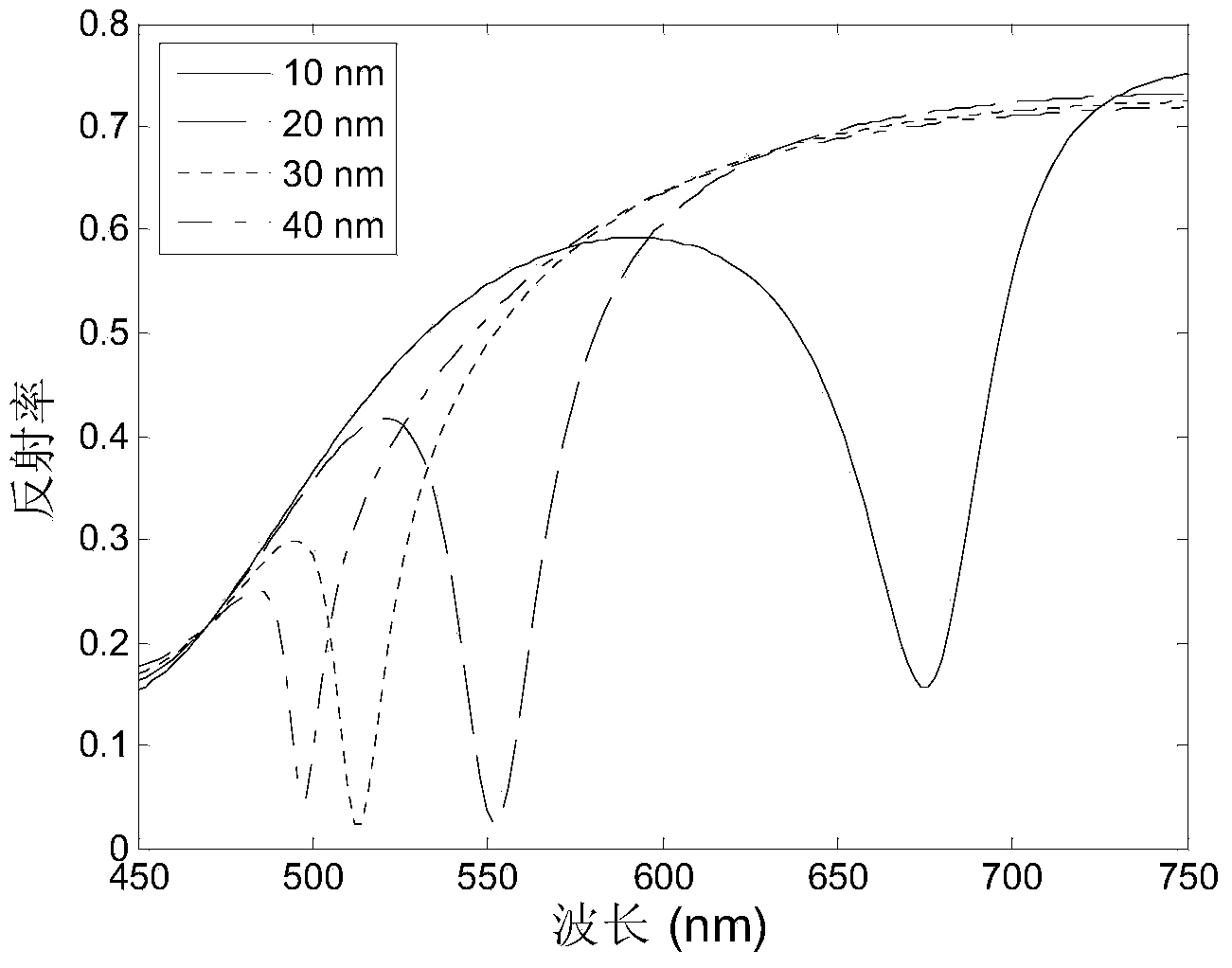

[0026] According to the principle of surface plasmon optics, the metal-medium-metal sandwich structure can be derived from Maxwell's equations to form a waveguide structure for transmitting light waves. The characteristics of the waveguide include: (1) light wave energy is transmitted along the metal-medium interface; (2) The waveguide mode is a resonant waveguide, that is, when other material parameters and geometric parameters are constant, the resonant conduction wavelength corresponds to the medium thickness parameter; (3) The waveguide transmission wave vector β is greater than the corresponding optical frequency in free space The wave vector β transmitted in 0 =2π / λ. The nano-gap detection structure, gap, and base structure in the present invention are as figure 1 As shown, 1-4 metal silver film layers, 1-6 metal silver film la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com