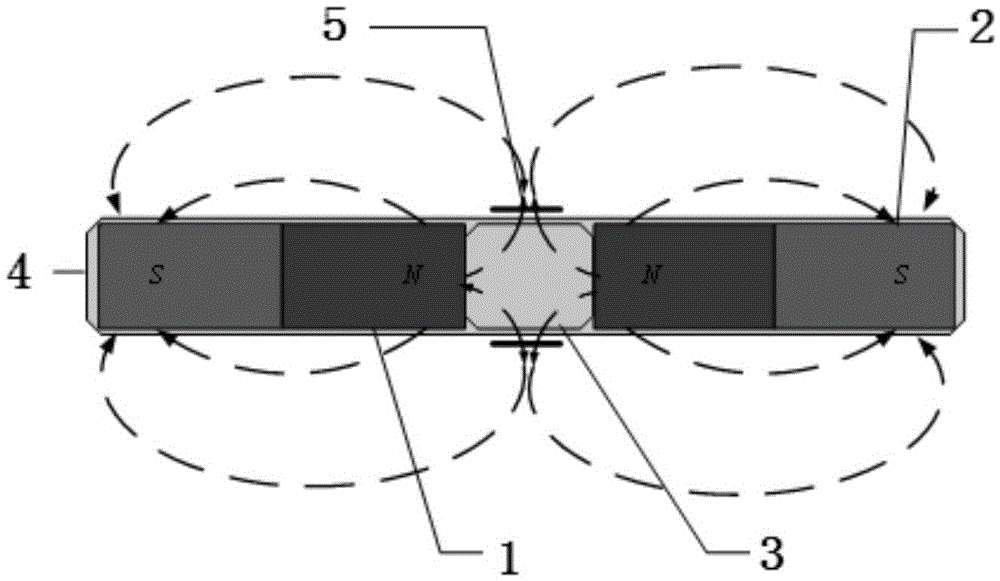

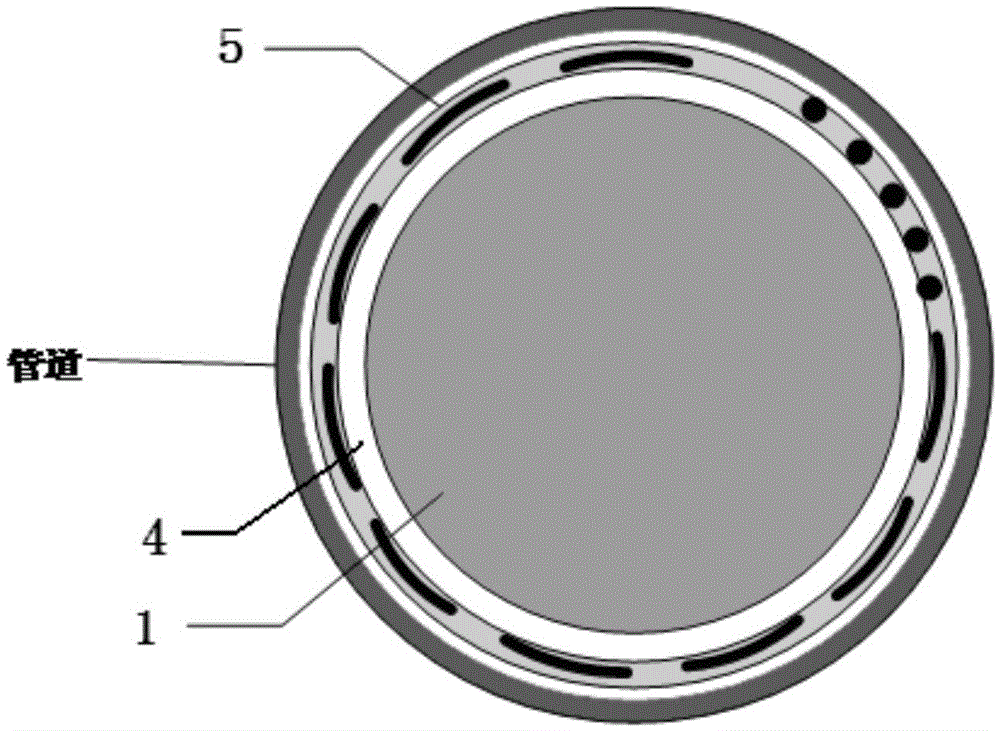

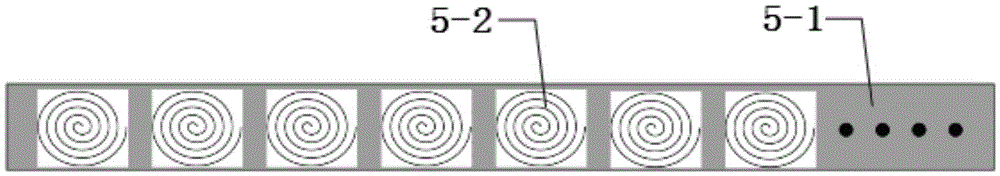

A full-circumference radial excitation electromagnetic ultrasonic transducer

An electromagnetic ultrasonic and transducer technology, applied in the direction of material analysis using acoustic wave emission technology, can solve the problems of large signal dispersion, complex detection system, poor precision, etc., to ensure uniform distribution, high detection efficiency, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] The tokamak divertor is an important part of the nuclear fusion reactor. Its structure is composed of an inner layer of CuCrZr heat exchange copper tube, a middle transitional pure copper layer and an outer tungsten block, which are connected as a whole by hot isobaric welding. However, due to factors such as unstable processing technology, body defects are prone to appear inside the heat exchange copper tube of the tokamak divertor. Utilize the full-circumference radial excitation electromagnetic ultrasonic transducer of the present invention to carry out electromagnetic ultrasonic detection on the typical body defects (length × width × depth: 2mm × 2mm × 0.2mm) inside the heat exchange copper tube of the tokamak divertor, and detect , place the full-circle radially excited electromagnetic ultrasonic transducer of the present invention in a non-heat-exchanging copper tube, pull the transducer axially, and carry out axial scanning of the defect. The detection results are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com