Electrochemical power supply separation membrane and preparation method thereof, electrochemical battery or capacitor

An electrochemical and diaphragm technology, applied in the field of electrochemistry, can solve the problems of low heat resistance temperature and poor electrolyte wettability, achieve good heat resistance, simple and effective preparation method, and improve safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

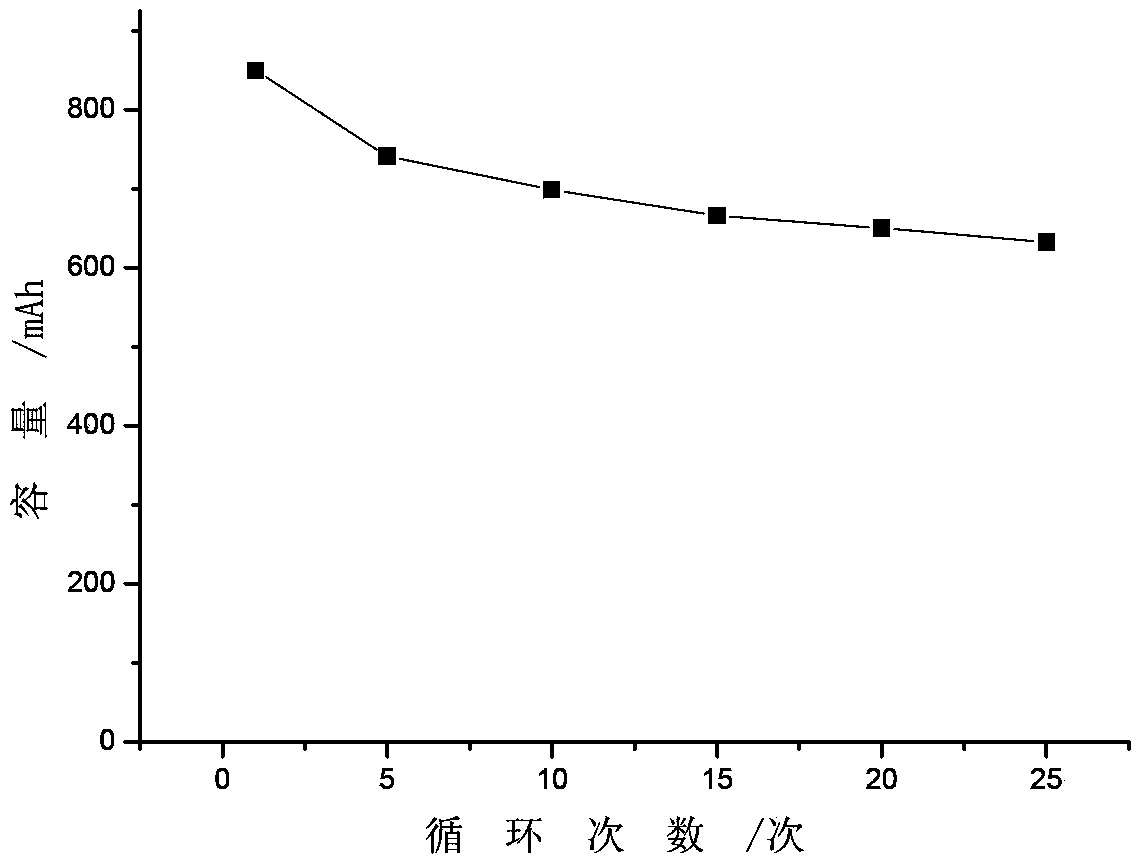

Image

Examples

Embodiment 1

[0031] A preparation method of electrochemical power supply diaphragm includes the following steps:

[0032] (1) Dissolve anhydrous aluminum chloride in deionized water to prepare an aluminum chloride solution with a mass concentration of 10%;

[0033] (2) After immersing a polypropylene diaphragm with a thickness of 10 μm in the aluminum chloride solution in (1) for 0.5 hours, take it out to obtain a polypropylene diaphragm with aluminum chloride solution attached to the surface;

[0034] (3) Place the above-mentioned polypropylene diaphragm with aluminum chloride solution in an ammonia atmosphere for 1 hour. After the aluminum chloride reaction is complete, take it out, wash with deionized water until the pH is neutral, and then place it at 80°C After being dried in the drying box for 24 hours, take it out to obtain an electrochemical power supply diaphragm. The diaphragm is a polypropylene diaphragm with an aluminum hydroxide coating layer on the surface. Among them, the thicknes...

Embodiment 2

[0037] A preparation method of electrochemical power supply diaphragm includes the following steps:

[0038] (1) Dissolve anhydrous aluminum chloride in ethanol to prepare an ethanol solution of aluminum chloride with a mass concentration of 20%;

[0039] (2) After immersing a polyethylene diaphragm with a thickness of 15 μm in the aluminum chloride ethanol solution in (1) for 1 hour, take it out to obtain a polyethylene diaphragm with aluminum chloride solution attached to the surface;

[0040] (3) Place the above-mentioned polyethylene membrane with aluminum chloride solution in an ammonia atmosphere for 2 hours. After the aluminum chloride reaction is complete, take it out, wash with deionized water until the pH is neutral, and then place it at 100°C After being dried for 16 hours in the drying box, the electrochemical power supply diaphragm is obtained, and the diaphragm is a polyethylene diaphragm with an aluminum hydroxide coating layer on the surface. Among them, the thicknes...

Embodiment 3

[0043] A preparation method of electrochemical power supply diaphragm includes the following steps:

[0044] (1) Dissolve anhydrous aluminum chloride in ether to prepare a 30% solution of aluminum chloride in ether;

[0045] (2) The polypropylene-polyethylene-polypropylene (PP-PE-PP) three-layer diaphragm with a thickness of 20μm is immersed in the aluminum chloride solution in (1) for 1.5 hours, and then taken out, and aluminum chloride is attached to the surface Solution PP-PE-PP three-layer diaphragm;

[0046] (3) Place the above-mentioned PP-PE-PP three-layer diaphragm with aluminum chloride solution in an ammonia atmosphere for 2 hours. After the aluminum chloride reaction is complete, take it out and wash with deionized water until the pH is neutral. Then, it was placed in a drying box at 70° C. for drying for 20 hours and then taken out to obtain an electrochemical power supply diaphragm. The diaphragm was a PP-PE-PP three-layer diaphragm with an aluminum hydroxide coating la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com