Method used for synthesizing thymalfasin

A thymosin and suitable technology, applied in the field of solid-phase synthesis of thymosin, can solve the problems of complicated operation, low product purity, time-consuming and labor-intensive, etc., and achieve the effect of easy purification and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

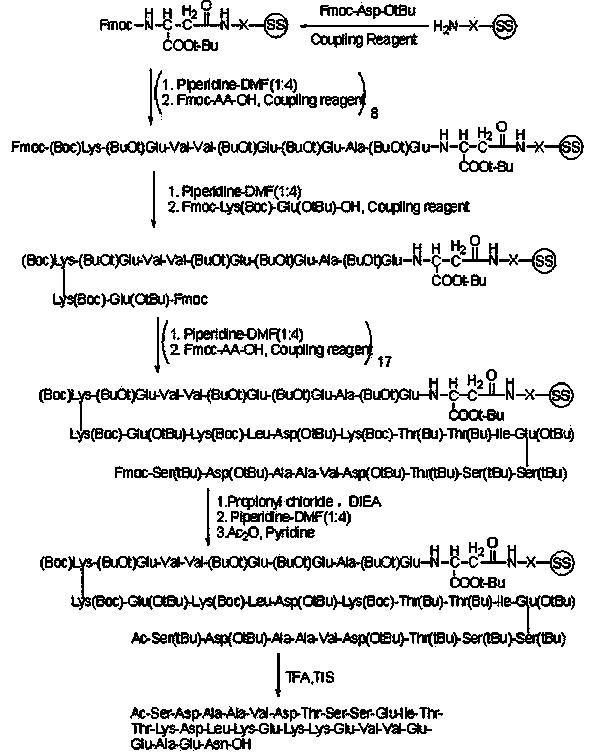

[0068] Embodiment 1: Synthesis of thymus fasin by one-by-one coupling method

[0069] step 1

[0070] Synthesis of Fmoc-Asp(RinkAmide-MBHA-Resin)-OtBu

[0071] Weigh Rink Amide MBHA resin (substitution degree 0.45mmol / g) (2.67 g, 1.0 equiv) into a solid-phase synthesis tube, add DCM (10mL), stir and swell at a temperature of 10-30°C for 30min, and remove the liquid by suction filtration. Then add DMF (10mL×2) to wash. Measure 20% (v / v, the same below) Piperidine / DMF solution (9.0 mL), add it to the solid-phase synthesis tube, control the temperature at 20-30°C and stir for 5 minutes, then remove the liquid by suction filtration. Measure 20% Piperidine / DMF solution (9.0 mL) again, add it to the solid-phase synthesis tube, control the temperature at 20-30°C and stir for 10 minutes, then remove the liquid by suction filtration. Measure DMF (10 mL×7) into the solid-phase synthesis tube for washing, and remove the liquid by suction filtration. Separately weigh Fmoc-Asp-OtBu (1....

Embodiment 2

[0084] Example 2: Synthesis of Thymus Faxin by Fragment Coupling Method

[0085] Ac-Ser-Asp-Ala-Ala-Val-Asp-Thr-Ser-Ser-Glu-Ile-Thr-Thr-Lys-Asp-Leu-Lys-Glu-Lys-Lys-Glu-Val-Val-Glu- Glu-Ala-Glu-Asn-OH (Thymofasin) Preparation

[0086] step 1

[0087] Synthesis of Fmoc-Asp(RinkAmide-MBHA-Resin)-OtBu

[0088] Weigh Rink Amide MBHA resin (substitution degree 0.45mmol / g) (2.67 g, 1.0 equiv) into a solid-phase synthesis tube, add DCM (10mL), stir and swell at a temperature of 10-30°C for 30min, and remove the liquid by suction filtration. Then add DMF (10mL×2) to wash. Measure 20% (v / v, the same below) Piperidine / DMF solution (9.0 mL), add it to the solid-phase synthesis tube, control the temperature at 20-30°C and stir for 5 minutes, then remove the liquid by suction filtration. Measure 20% Piperidine / DMF solution (9.0 mL) again, add it to the solid-phase synthesis tube, control the temperature at 20-30°C and stir for 10 minutes, then remove the liquid by suction filtration. Me...

Embodiment 3

[0101] Example 3: Synthesis of Thymus Faxin by Capping with Special Reagents

[0102] Ac-Ser-Asp-Ala-Ala-Val-Asp-Thr-Ser-Ser-Glu-Ile-Thr-Thr-Lys-Asp-Leu-Lys-Glu-Lys-Lys-Glu-Val-Val-Glu- Glu-Ala-Glu-Asn-OH (Thymofasin) Preparation

[0103] step 1

[0104] Synthesis of Fmoc-Asp(RinkAmide-MBHA-Resin)-OtBu

[0105] Weigh Rink Amide MBHA resin (substitution degree 0.45mmol / g) (2.67 g, 1.0 equiv) into a solid-phase synthesis tube, add DCM (10mL), stir and swell at a temperature of 10-30°C for 30min, and remove the liquid by suction filtration. Then add DMF (10mL×2) to wash. Measure 20% (v / v, the same below) Piperidine / DMF solution (9.0 mL), add it to the solid-phase synthesis tube, control the temperature at 20-30°C and stir for 5 minutes, then remove the liquid by suction filtration. Measure 20% Piperidine / DMF solution (9.0 mL) again, add it to the solid-phase synthesis tube, control the temperature at 20-30°C and stir for 10 minutes, then remove the liquid by suction filtratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Peak area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com