Method for preparing and curing hydroxyl-terminated liquid fluoropolymer

A curing method and technology of liquid fluorine, which is applied in the field of preparation and curing of hydroxyl-terminated liquid fluoropolymers, can solve the problems of affecting the service life of the product and prone to degradation, and achieve good mechanical properties, low cost, and simple and easy process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

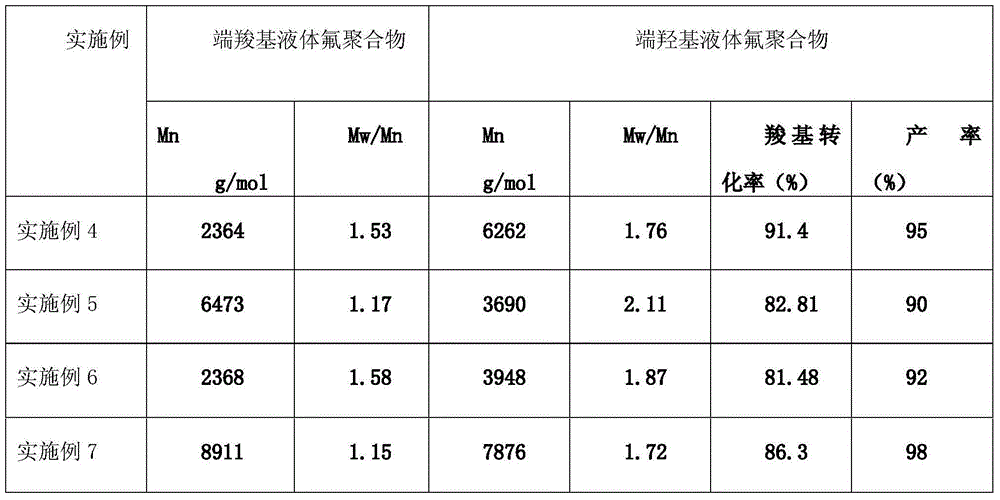

Embodiment 1

[0018] With 5.02g carboxyl-terminated liquid fluoropolymer (vinylidene fluoride-hexafluoropropylene copolymer, the carboxyl mass percentage content is 1.16%, the number average molecular weight is 3058, and the weight average molecular weight is 3752, and the following examples are all of this material if there is no description. ) was dissolved in 50ml tetrahydrofuran, added to a 250ml there-necked flask, added sodium borohydride (0.0490g, 1.29mmol), stirred for 45 minutes, added iodine (0.1641g, 0.65mmol) in tetrahydrofuran (10ml), stirred at 70°C React for 2 hours. Add 10ml of hydrochloric acid to quench the reaction, the system will have a white precipitate, which is removed by filtration. After washing with a saturated aqueous solution of sodium sulfite, and then repeatedly washing with deionized water, the product was vacuum-dried at 70° C. to constant weight to obtain a white viscous liquid with a yield of 94%. The number average molecular weight of the product is 5155...

Embodiment 2

[0020] 10.07g of carboxyl-terminated liquid fluoropolymer (vinylidene fluoride-hexafluoropropylene copolymer, carboxyl mass percentage content is 1.16%, number average molecular weight is 3058, weight average molecular weight is 3752, and the following examples are all this material if there is no description. ) was dissolved in 150ml tetrahydrofuran, added to a 500ml there-necked flask, added sodium borohydride (0.1473g, 3.90mmol), stirred for 45 minutes, added iodine (0.3294g, 1.30mmol) in tetrahydrofuran (50ml), stirred at 50°C React for 5 hours. Add 30ml of hydrochloric acid to quench the reaction, the system will have a white precipitate, which is removed by filtration. After washing with a saturated aqueous solution of sodium sulfite, and then repeatedly washing with deionized water, the product was vacuum-dried at 70° C. to constant weight to obtain a white viscous liquid with a yield of 97%. The number average molecular weight of the product is 3948g / mol, the molecula...

Embodiment 3

[0022] 20.10g of carboxyl-terminated liquid fluoropolymer (vinylidene fluoride-hexafluoropropylene copolymer, carboxyl mass percentage content is 1.16%, number-average molecular weight is 3058, weight-average molecular weight is 3752, and the following examples are all this material if there is no description. ) was dissolved in 300ml tetrahydrofuran, added to a 1000ml there-necked flask, added sodium borohydride (0.3900g, 10.31mmol), stirred for 45 minutes, added iodine (0.6575g, 2.60mmol) in tetrahydrofuran (80ml), stirred at 25°C React for 12 hours. Add 50ml of hydrochloric acid to quench the reaction, the system will have a white precipitate, which is removed by filtration. After washing with a saturated aqueous solution of sodium sulfite, and then repeatedly washing with deionized water, the product was vacuum-dried at 70° C. to constant weight to obtain a white viscous liquid with a yield of 98%. The number average molecular weight of the product is 4876g / mol, the molec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com