Corrosion-resistance rust-conversion coating material with rust

A rust-to-rust, corrosion-resistant technology, applied in anti-corrosion coatings, coatings and other directions, can solve problems such as restricting the development of anti-rust coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

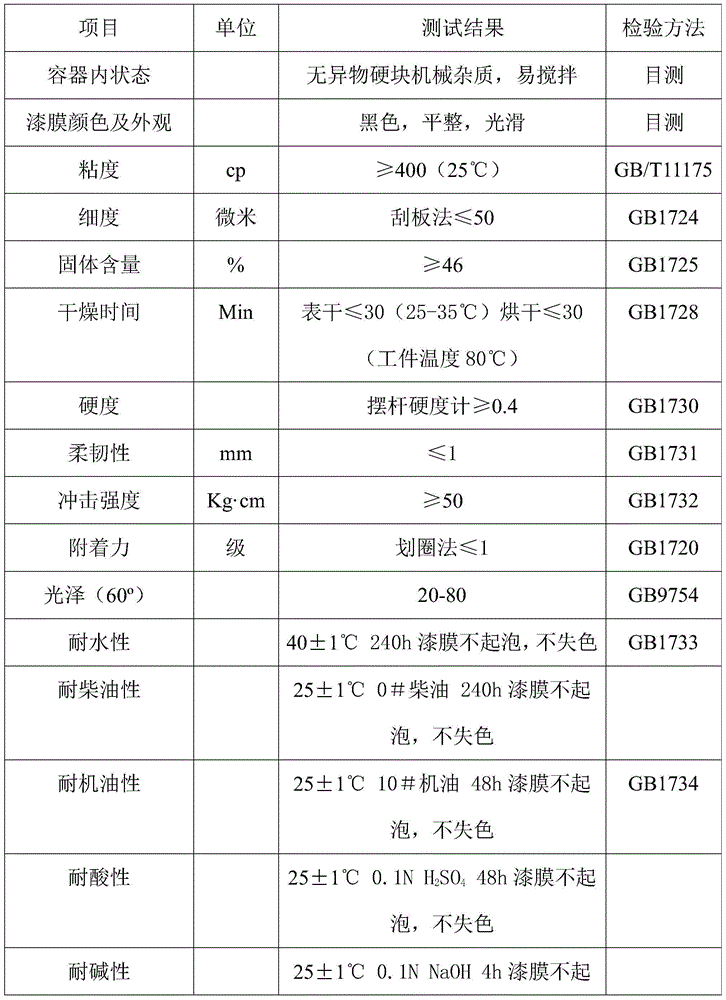

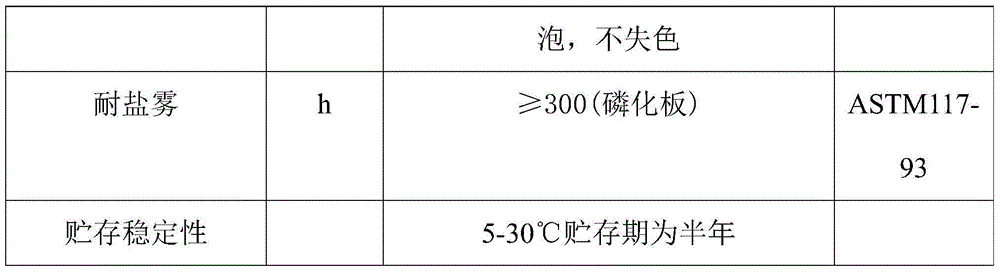

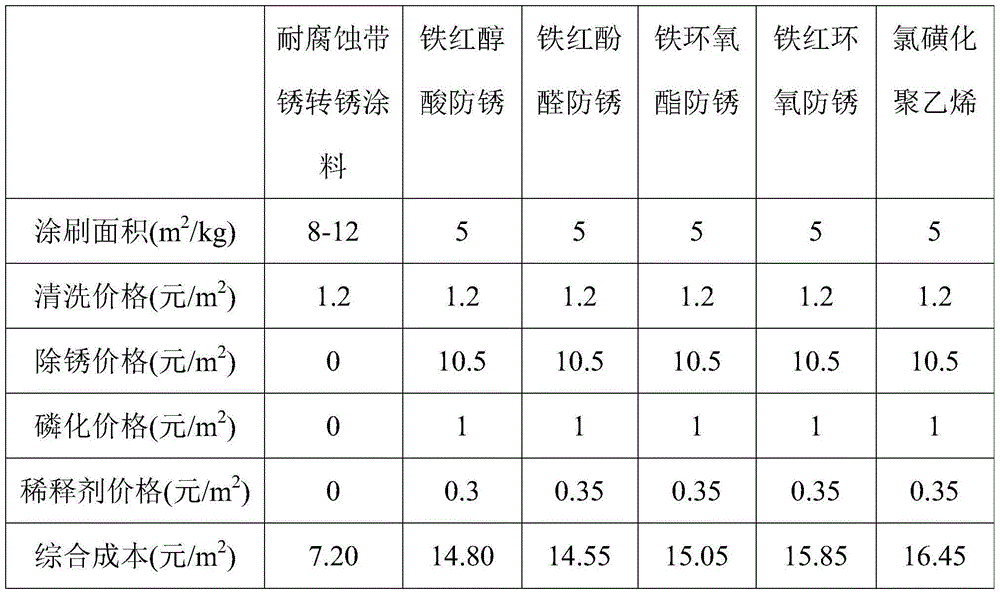

Examples

Embodiment 1

[0025] A kind of anti-corrosion rust-reversing paint with rust that the embodiment of the present invention proposes, comprises:

[0026] Weigh 4 parts of carneylic acid, 0.25 part of wetting agent, 0.3 part of dispersant, 0.15 part of defoamer, 0.1 part of anti-flash rust agent and 0.4 part of thickener in parts by weight and add them to the Stir evenly in 800wt% distilled water to obtain the intermediate material; among them, carbonic acid is prepared by the following process: the raw material gallnut is crushed by a mill and then sieved, and then placed in a wooden container and added with hot water at a temperature of 75 ° C for 1 hour. , after the coarse filtration, the extraction was repeated 4 times, and the granular objects were precipitated by cooling in cold water, and the carnic acid was obtained through separation, vacuum concentration and drying;

[0027] Weigh 5 parts of modified wollastonite, 1 part of mica and 2 parts of barite and stir evenly to obtain a modif...

Embodiment 2

[0031] A kind of anti-corrosion rust-reversing paint with rust that the embodiment of the present invention proposes, comprises:

[0032] Take by weight 4 parts of carneylic acid, 0.5 part of wetting agent, 0.25 part of dispersant, 0.3 part of defoamer, 0.15 part of anti-flash rust agent and 0.4 part of thickener and add to 600wt by weight of carneylic acid % of distilled water was stirred evenly to obtain the intermediate material; among them, carbonic acid was prepared by the following process: the raw material gallnut was crushed by a mill and then sieved, then placed in a wooden container and added with hot water at a temperature of 75°C for 1 hour, Coarse filtration, repeated extraction 4 times, cooling water to 0°C to precipitate granular objects, after separation, vacuum concentration, and drying, carnic acid was obtained;

[0033] Weigh 6 parts of modified wollastonite, 1 part of mica and 2 parts of barite by weight and stir evenly to obtain modified fillers. Modified ...

Embodiment 3

[0037] A kind of anti-corrosion rust-reversing paint with rust that the embodiment of the present invention proposes, comprises:

[0038] Take by weight 5 parts of carneylic acid, 0.4 part of wetting agent, 0.25 part of dispersant, 0.15 part of defoamer, 0.2 part of anti-flash rust agent and 0.45 part of thickener and add to 700wt by carney acid weight % distilled water was stirred evenly to obtain the intermediate material; among them, carbonic acid was prepared by the following process: the raw material gallnut was crushed by a grinder and then sieved, then placed in a wooden container and added with hot water at a temperature of 80°C for 2 hours, and crude Filtration, repeated extraction 3 times, cold water cooling to 0 ° C to precipitate granular objects, separation, vacuum concentration, drying to obtain carneylic acid;

[0039] Weigh 5 parts by weight of modified wollastonite, 1 part of mica and 3 parts of barite and stir evenly to obtain modified fillers. Modified wolla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com