Processing system and carbonization pile-forming method used for ground stabilization

A treatment system and foundation reinforcement technology, applied in sheet pile walls, soil protection, infrastructure engineering, etc., can solve problems such as leaking surface layers, difficulty in reinforcement, etc., and achieve the effect of improving efficiency and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

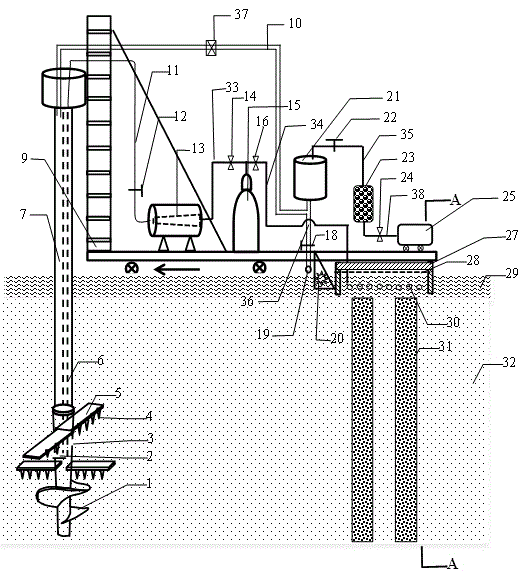

[0046] a. select anionic surfactant type foaming agent, foaming agent and distilled water are mixed with foaming liquid by mass ratio 1:30, and the half-life of its foam is about 30min, and pack in the foaming device 13; And dry active Magnesium oxide is packed into curing agent storage tank 21; When the radius of stirring blade 5 is less than 200 mm, when the rotational speed of stirring shaft 7 is less than 30 r / min, the lifting speed is less than 0.5 m / min, and the pressure of regulating pressure regulating valve a14 is respectively 150 kPa, for carbon dioxide gas foaming, and adjust the pressure of the pressure regulating valve c24 to 200 kPa, and perform gas drying;

[0047] b. Move the helical cutting drill bit 1 to a preset pile position, start the stirring device in the penetrating state, the helical cutting drill bit 1 cuts the soil, and the stirring blade 5 breaks the soil and stirs and penetrates into the preset pile position Stop at the predetermined depth of 10m; ...

Embodiment 2

[0054] a. select protein foaming agent, and foaming agent and distilled water are formulated into foaming liquid by mass ratio 1:40, and the half-life of foam is about 45min, and pack in foaming device 13; Magnesium is packed into curing agent storage tank 21; when the radius of stirring blade 5 is 200-300 mm, and the rotation speed of stirring shaft 7 is 30-100 r / min, the lifting speed is 0.5-1.0 m / min, adjust the pressure regulating valve The pressure of a14 is 300 kPa, and the carbon dioxide gas is foamed, and the pressure of the pressure regulating valve c24 is adjusted to 300 kPa, and the gas is dried;

[0055] b. Move the helical cutting drill bit 1 to a preset pile position, start the stirring device in the penetrating state, the helical cutting drill bit 1 cuts the soil, and the stirring blade 5 breaks the soil and stirs and penetrates into the preset pile position Stop at the predetermined depth of 20m;

[0056] c. Start the stirring device in the lifting state, open...

Embodiment 3

[0062] a. Select anionic surfactant foaming agent and protein foaming agent, and mix them at a mass ratio of 1:1. The foaming speed of anionic surfactant foaming agent is faster than that of protein foaming agent, but the foam stabilization time is short In the protein foaming agent, and mixed foaming agent and distilled water by mass ratio 1:40 to prepare foaming liquid, and pack in the foaming device 13; And dry active magnesium oxide and quicklime powder by mass ratio : 1 mixed into curing agent storage tank 21; when the radius of stirring blade 5 was 300-400 mm, and the rotating speed of stirring shaft 7 was 30-100 r / min, the lifting speed was 0.5-1.0 m / min, adjust The pressure of the pressure valve a14 is 400 kPa, and the carbon dioxide gas is foamed, and the half-life of the foam is about 30 minutes, and the pressure of the pressure regulating valve c24 is adjusted to 400 kPa, and the gas is dried;

[0063] b. Move the helical cutting drill bit 1 to a preset pile positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com