Blue-light-prevention screen protective membrane and preparation method thereof

A screen protection film, anti-blue light technology, applied in chemical instruments and methods, lamination, coating and other directions, can solve the problems of high production cost and complex preparation process, and achieve the effect of low cost, simple preparation process and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

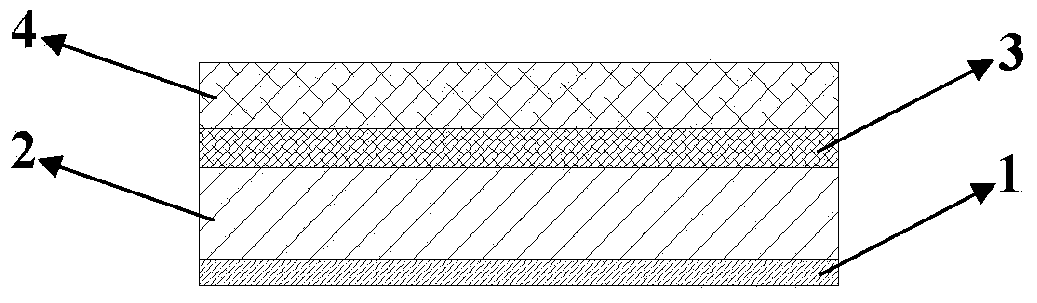

[0030] preparation figure 1 Anti-blue light screen protector shown.

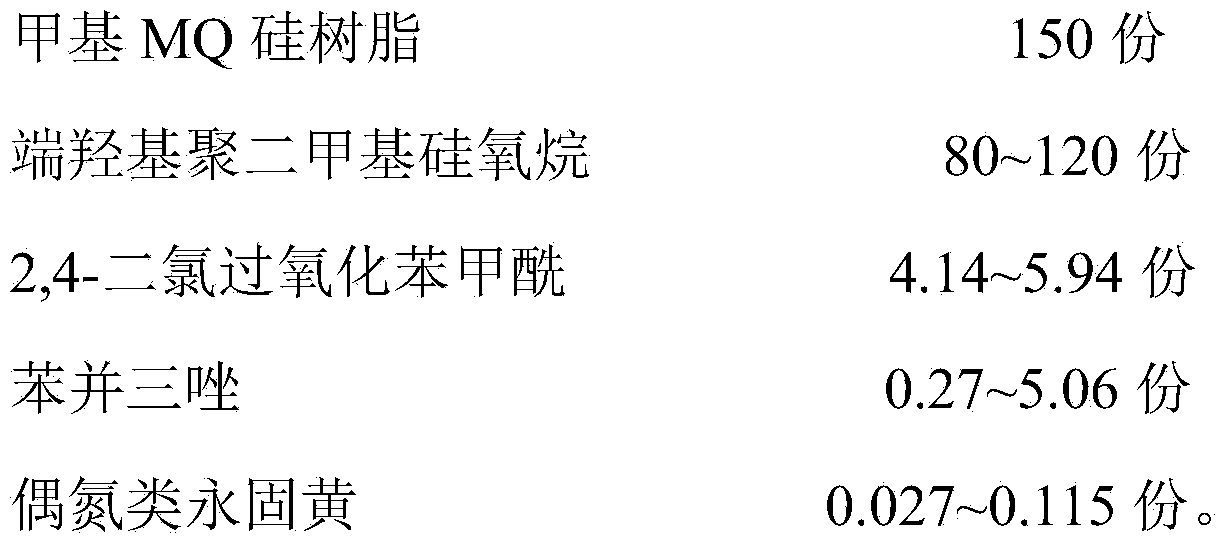

[0031] The coating solution of the blue light blocking layer consists of the following components in parts by mass:

[0032]

[0033] Xylene was added to prepare a blue light blocking layer coating solution with a solid content of 30%.

[0034] On one side of the high-transparency polyester film with a thickness of 35 μm, use a micro-gravure to coat the coating solution of the super-hard scratch-resistant coating, and UV curing to obtain a dry film thickness of 3 μm super-hard scratch-resistant coating; on the high-transparency polyester film The other side was coated with the blue light blocking layer coating solution with a comma roller, and then heat-cured at 190° C. for 4 minutes to obtain a blue light blocking layer with a dry film thickness of 10 μm.

[0035] Before winding, a 50 μm fluorine release film layer is pasted on the other side of the blue light blocking layer to obtain an anti-blue ligh...

Embodiment 2

[0037] preparation figure 1 Anti-blue light screen protector shown.

[0038] The coating solution of the blue light blocking layer consists of the following components in parts by mass:

[0039]

[0040] An appropriate amount of solvent toluene was added to prepare a blue light blocking layer coating solution with a solid content of 30%.

[0041] On one side of the high-transparency polyester film with a thickness of 100 μm, use a micro-gravure to coat the coating liquid of the super-hard scratch-resistant coating, and UV curing to obtain a dry film thickness of 4 μm super-hard scratch-resistant coating; on the high-transparency polyester film The other side was coated with the blue light blocking layer coating solution with a comma roller, and then thermally cured at 180° C. for 5 minutes to obtain a blue light blocking layer with a dry film thickness of 16 μm.

[0042] Before winding, a 75 μm fluorine release film layer is pasted on the other side of the blue light bloc...

Embodiment 3

[0044] preparation figure 1 Anti-blue light screen protector shown.

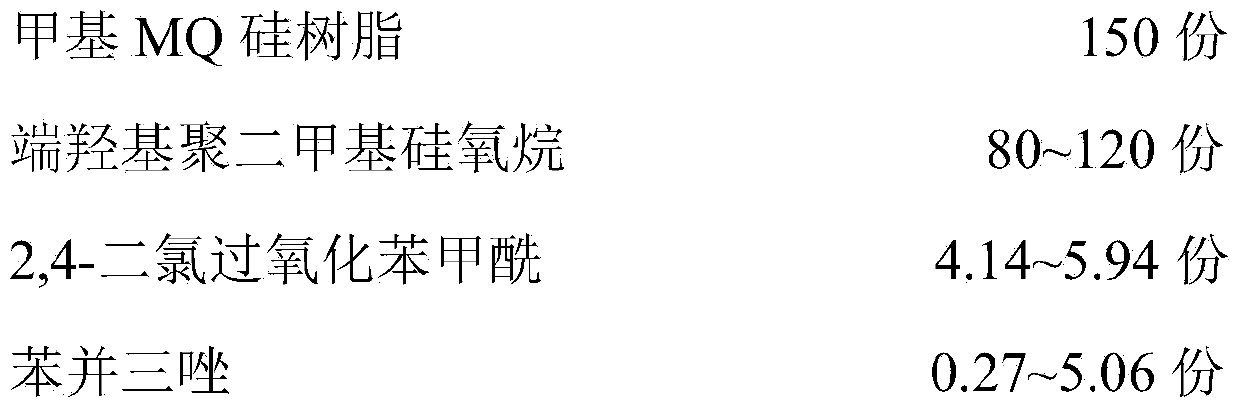

[0045] The coating solution of the blue light blocking layer consists of the following components in parts by mass:

[0046]

[0047]

[0048] An appropriate amount of solvent toluene was added to prepare a blue light blocking layer coating solution with a solid content of 30%.

[0049] On one side of the high-transparency polyester film with a thickness of 75 μm, use a micro-gravure to coat the coating solution of the super-hard scratch-resistant coating, and UV curing to obtain a dry film thickness of 4 μm super-hard scratch-resistant coating; on the high-transparency polyester film The other side was coated with the blue light blocking layer coating solution with a comma roller, and then thermally cured at 180° C. for 5 minutes to obtain a blue light blocking layer with a dry film thickness of 15 μm.

[0050] Before winding, a 75 μm fluorine release film layer is pasted on the other side of the bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com