Method for preparing nano trimanganese tetroxide

A technology of trimanganese tetraoxide and nanometer, which is applied in the direction of nanotechnology, nanotechnology, ferrous iron oxide, etc., can solve the problems of high cost, non-environmental protection, complex processing methods of nanometer trimanganese tetraoxide, etc., and achieve simple processing , good economic benefits, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Remove impurities from the collected banana peels, wash them with water, and dry them at room temperature for 5 days, then take 3 kilograms of dried banana peels and put them into 30 kilograms of deionized water at a temperature of 90 ° C, and make the deionized water Ionized water was refluxed for 5 hours, then filtered to obtain the banana peel extract, which was 1.5 kilograms through weighing the banana peel extract, and the banana peel extract obtained was added dropwise to 8.5 kilograms of concentration in the potassium permanganate solution of 1%, while Stir continuously for 5 hours, then filter to obtain a brown precipitate, and dry the brown precipitate at a temperature of 60° C. to finally obtain the final product.

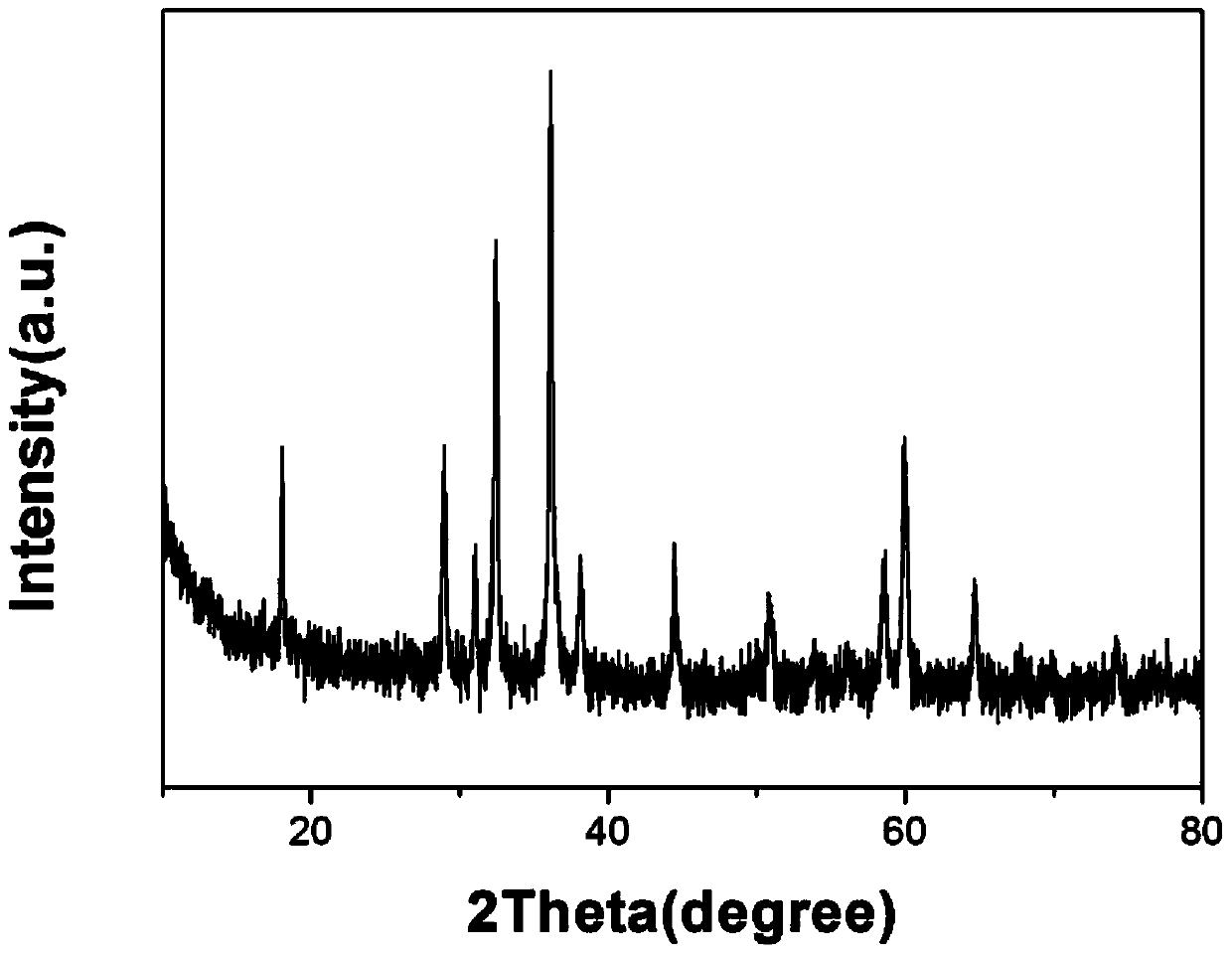

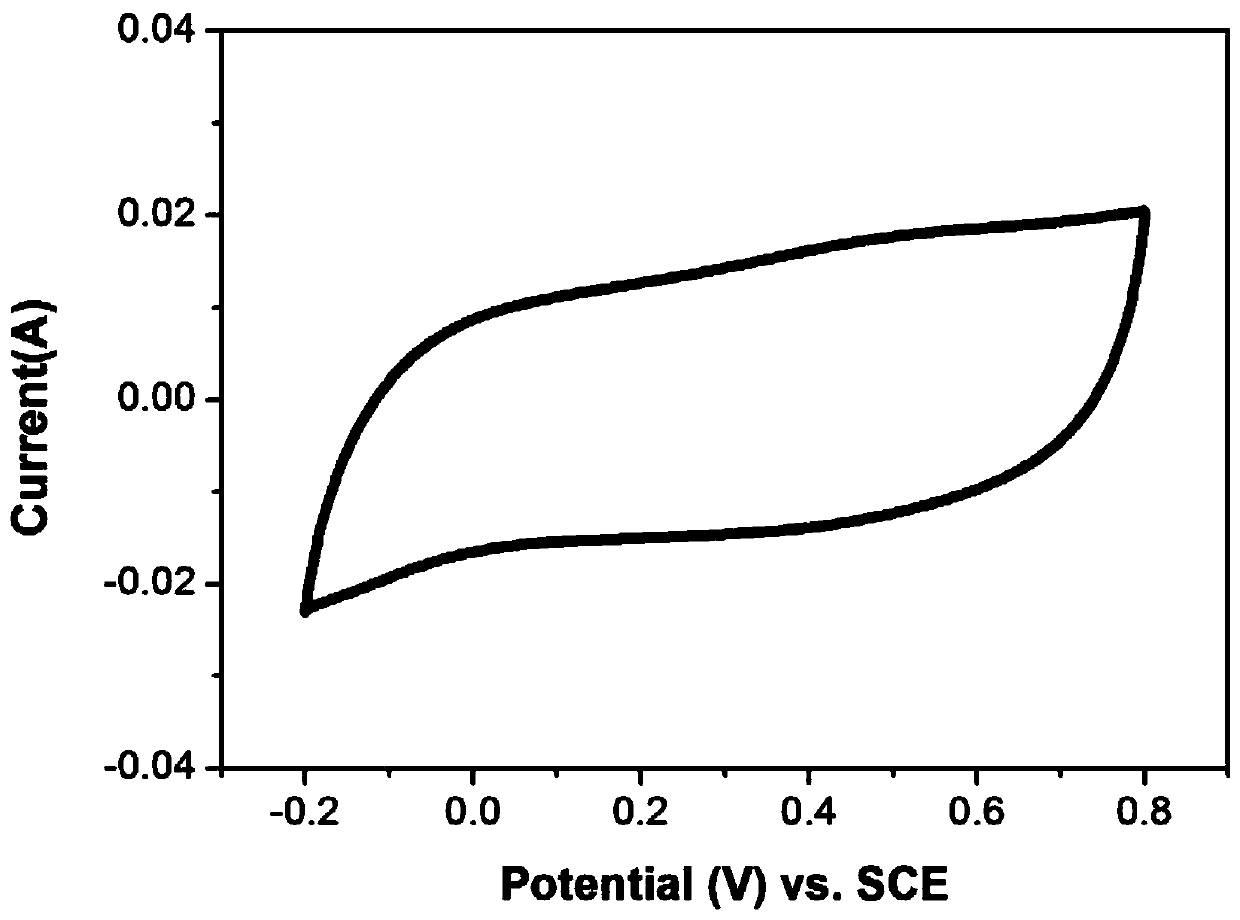

[0030] Detection: XRD characterization shows that the product is trimanganese tetraoxide (attached figure 1 shown), the derivative peak of the sample is related to Mn 3 o 4 (Card No. 80-0382) Standard cards fit better. SEM photographs of the po...

Embodiment 2

[0033]Remove impurities from the collected banana peels, wash them with water, and dry them at room temperature for 4 days. Then take 1.5 kg of dried banana peels and put them into 20 kg of deionized water at a temperature of 85°C. Ionized water was refluxed for 7 hours, then filtered to obtain the banana peel extract, and it was 1 kilogram through weighing the banana peel extract, and the banana peel extract obtained was added dropwise to 9.5 kilograms of concentration in the potassium permanganate solution of 7%, while Stir continuously for 3 hours, then filter to obtain a brown precipitate, and dry the brown precipitate at a temperature of 55° C. to finally obtain the final product.

[0034] Detection: XRD characterization shows that the product is trimanganese tetraoxide, and the derivative peak of the sample is related to Mn 3 o 4 (The card number is 80-0382) The standard card fits well. From the scanning electron microscope photos of the obtained powder, it can be seen ...

Embodiment 3

[0037] Remove impurities from the collected banana peels, wash them with water, and dry them for 3.5 days at room temperature, then take 4.5 kg of dried banana peels and put them into 10 kg of deionized water at a temperature of 95°C, and make the deionized water Ionized water was refluxed for 10 hours, then filtered to obtain the banana peel extract, which was 1.5 kilograms through weighing the banana peel extract, and the obtained banana peel extract was added dropwise to 27 kilograms of concentration in the potassium permanganate solution of 5%, while Stir continuously for 4 hours, then filter to obtain a brown precipitate, and dry the brown precipitate at a temperature of 65° C. to finally obtain the final product.

[0038] Detection: XRD characterization shows that the product is trimanganese tetraoxide, and the derivative peak of the sample is related to Mn 3 o 4 (The card number is 80-0382) The standard card fits well. From the scanning electron microscope photos of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com