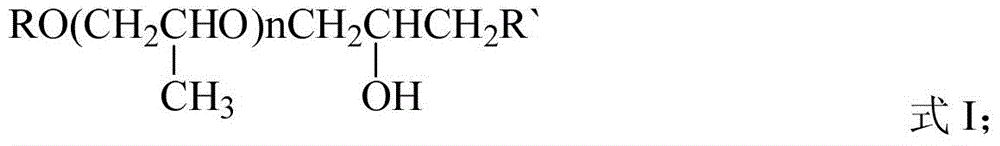

Fatty alcohol polyoxypropylene ether sulfobetaine and alkali-free composite oil displacement composition

A technology of alcohol polyoxypropylene ether and sulfobetaine, which is applied in the directions of drilling composition, sulfonate preparation, chemical instrument and method, etc., can solve problems affecting the normal use of medium and low temperature oil reservoirs and high production cost of betaine , the problem of high price of long-chain tertiary amines, to achieve the effect of improving the balance of hydrophilic and lipophilic, improving interface properties and salt resistance, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

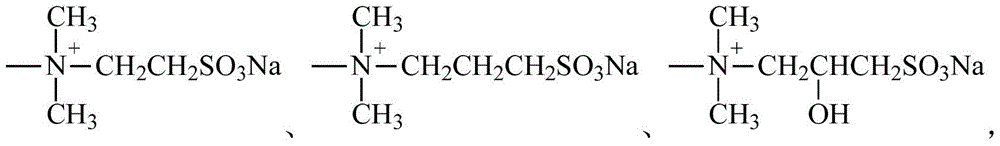

[0033] Embodiment 1N-[octadecyl polyoxypropylene ether (2)-2-hydroxypropyl]-N,N-dimethyl hydroxypropyl sulfobetaine

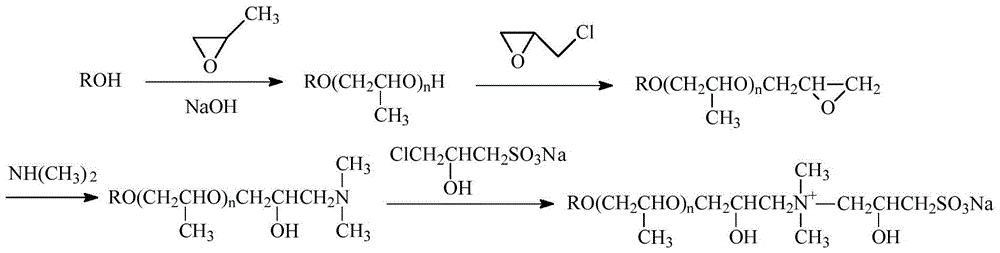

[0034] This example provides a kind of N-[octadecyl polyoxypropylene ether (2)-2-hydroxypropyl]-N,N-dimethyl hydroxypropyl sulfobetaine, which is synthesized by the following steps:

[0035](1) Etherification reaction: Add 0.1mol n-octadecylpolyoxypropylene ether (2), 1.7g tetrabutylammonium bromide, 8.0g solid NaOH, add n-hexane as a solvent, heat up to 65°C, add 10.2g of epichlorohydrin dropwise to react at constant temperature for 3 hours, then wash with water until neutral.

[0036] (2) amination reaction: in the there-necked flask equipped with electromagnetic stirring, thermometer, reflux condenser and drying tube, add the product of 0.05mol above-mentioned etherification reaction, 10.0g mass fraction is the dimethylamine aqueous solution of 30-33%, Ethanol was added as a solvent, the reaction was stirred at 65°C for 1 h, and the ethanol was removed by r...

Embodiment 2

[0038] Embodiment 2N-[jubet alkyl polyoxypropylene ether (3)-2-hydroxypropyl]-N,N-dimethyl hydroxypropyl sulfobetaine

[0039] This example provides a kind of N-[jubet alkyl polyoxypropylene ether (3)-2-hydroxypropyl]-N,N-dimethyl hydroxypropyl sulfobetaine, which is synthesized by the following steps:

[0040] (1) etherification reaction: add 0.10mol2-octyl-dodecylpolyoxypropylene ether (3), 1.7g tetrabutylammonium bromide, Add 8.0g of solid NaOH, add n-hexane as solvent, heat up to 80°C, add dropwise 10.2g of epichlorohydrin to react at constant temperature for 4 hours, then wash with water until neutral.

[0041] (2) amination reaction: in the there-necked flask equipped with electromagnetic stirring, thermometer, reflux condenser and drying tube, add the product of 0.05mol above-mentioned etherification reaction, 10.0g mass fraction is the dimethylamine aqueous solution of 30-33%, Ethanol was added as a solvent, the reaction was stirred at 75°C for 1 h, and the ethanol wa...

Embodiment 3

[0043] Example 3N-[tetradecyl polyoxypropylene ether (12)-2-hydroxypropyl]-N,N-dimethylpropanesulfobetaine

[0044] This example provides a kind of N-[tetradecyl polyoxypropylene ether (12)-2-hydroxypropyl]-N,N-dimethylpropane sulfobetaine, which is synthesized by the following steps:

[0045] (1) Etherification reaction: Add 0.1mol tetradecyl polyoxypropylene ether (12), 1.7g tetrabutylammonium bromide, and 8.0g solid NaOH to a three-necked flask equipped with electric stirring, a thermometer and a reflux condenser , add n-hexane as a solvent, heat up to 80°C, add 10.2g of epichlorohydrin dropwise and react at constant temperature for 4 hours, then wash with water until neutral.

[0046] (2) amination reaction: in the there-necked flask equipped with electromagnetic stirring, thermometer, reflux condenser and drying tube, add the product of 0.05mol above-mentioned etherification reaction, 10.0g mass fraction is the dimethylamine aqueous solution of 30-33%, Ethanol was added ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com