Preparation process for extracting green tea polyphenols from tea

A preparation process and technology of tea polyphenols, applied in the direction of organic chemistry, etc., can solve the problems of low product yield and purity, destruction of effective components, and high production cost, and achieve the effects of good adsorption effect, improved leaching rate, and high finished product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

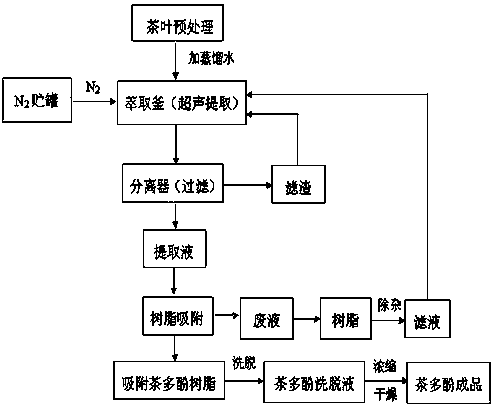

[0031] The invention provides a preparation process for extracting tea polyphenols from tea, comprising the following steps:

[0032] Step 1, tea pretreatment: select high-quality tea leaves, which are Guiping Xishan tea leaves, grind them after drying, and pass through a 60-80 mesh sieve to obtain tea powder;

[0033] Step 2, nitrogen protection: put the tea powder in step 1 in the extraction kettle, add distilled water and mix well, the mass ratio of solid to liquid is 1:6-1:15, use a vacuum pump to deoxidize, and then pass in pure nitrogen;

[0034] Step 3: Ultrasonic extraction: After nitrogen gas is introduced, ultrasonic extraction is carried out at a constant temperature to obtain a tea polyphenol solution containing residues;

[0035] Step 4, separation: filter the tea polyphenol solution containing residue in step 3 through a separator, and separate to obtain extract and filter residue;

[0036] Step 5, resin adsorption: use polyamide resin or NKA macroporous resin t...

Embodiment 1

[0045] Such as figure 1 Shown, the preparation process of extracting tea polyphenols:

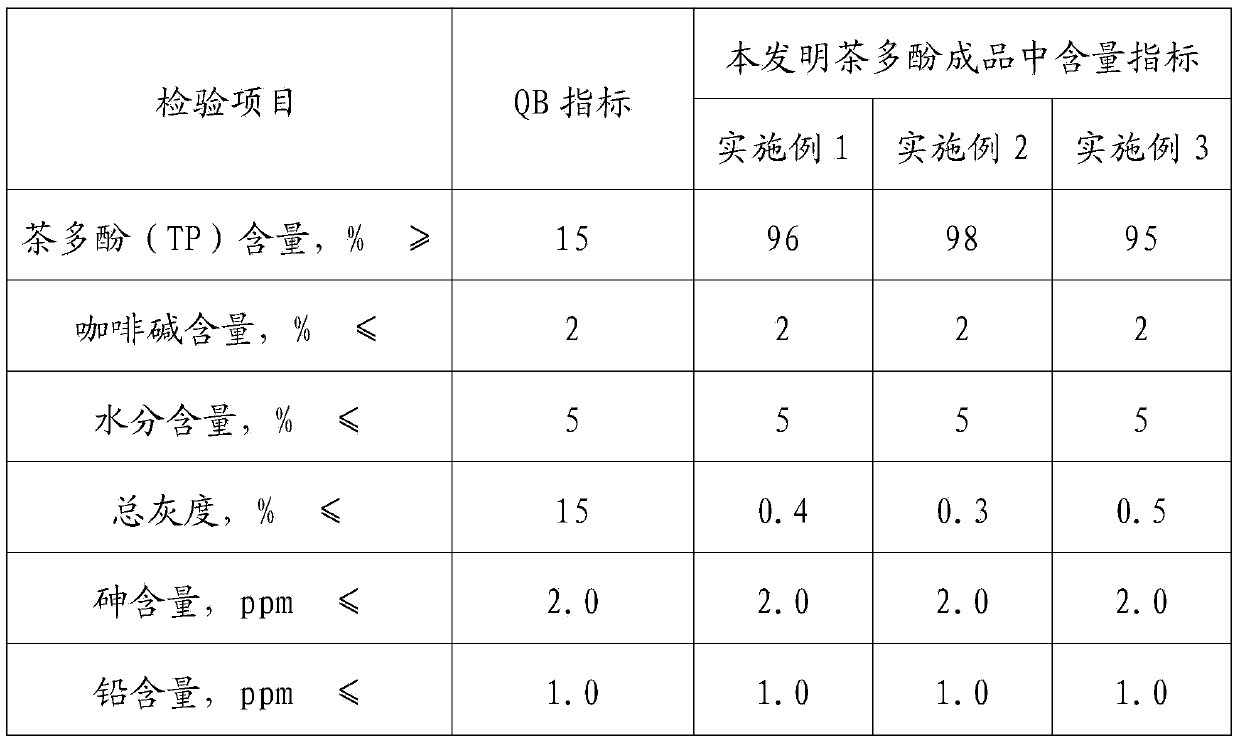

[0046]Select 1000kg of high-quality Guiping Xishan tea, put the tea leaves in a dryer, and dry them at a temperature of 70°C until the dryness reaches 98%. After drying, grind them and pass through a 60-mesh sieve to obtain tea powder; In the extraction kettle, add 10000kg of distilled water and mix well, deoxygenate the distilled water with a vacuum pump, and then pass in pure nitrogen gas; after passing in nitrogen gas, carry out ultrasonic extraction at a constant temperature of 50°C, extract twice, each time for 20min, and obtain the The tea polyphenol solution of the residue; the tea polyphenol solution containing the residue is filtered through a separator to separate the extract and the filter residue, and the obtained filter residue is returned for ultrasonic extraction; the polyamide resin is used to absorb the tea polyphenol in the extract to obtain Adsorb the resin and waste liq...

Embodiment 2

[0049] Such as figure 1 Shown, the preparation process of extracting tea polyphenols:

[0050] Select 1000kg of high-quality Guiping Xishan tea, put the tea leaves in a dryer, dry them at a temperature of 100°C until the dryness reaches 98%, grind them after drying, and pass through a 60-mesh sieve to obtain tea powder; In the extraction kettle, add 6000kg of distilled water and mix well, use a vacuum pump to deoxygenate the distilled water, and then pass in pure nitrogen; after passing in nitrogen, perform ultrasonic extraction at a constant temperature of 30°C, extract 3 times, each time for 15min, and obtain The tea polyphenol solution of the residue; the tea polyphenol solution containing the residue is filtered through a separator to separate the extract and the filter residue, and the obtained filter residue is returned for ultrasonic extraction; the polyamide resin is used to absorb the tea polyphenol in the extract to obtain Adsorb the resin and waste liquid of tea po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com