Synthesis method of zinc acrylate resin

A technology for the synthesis of zinc acrylate, which is applied to paints, coatings, antifouling/underwater coatings, etc. Simple control and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

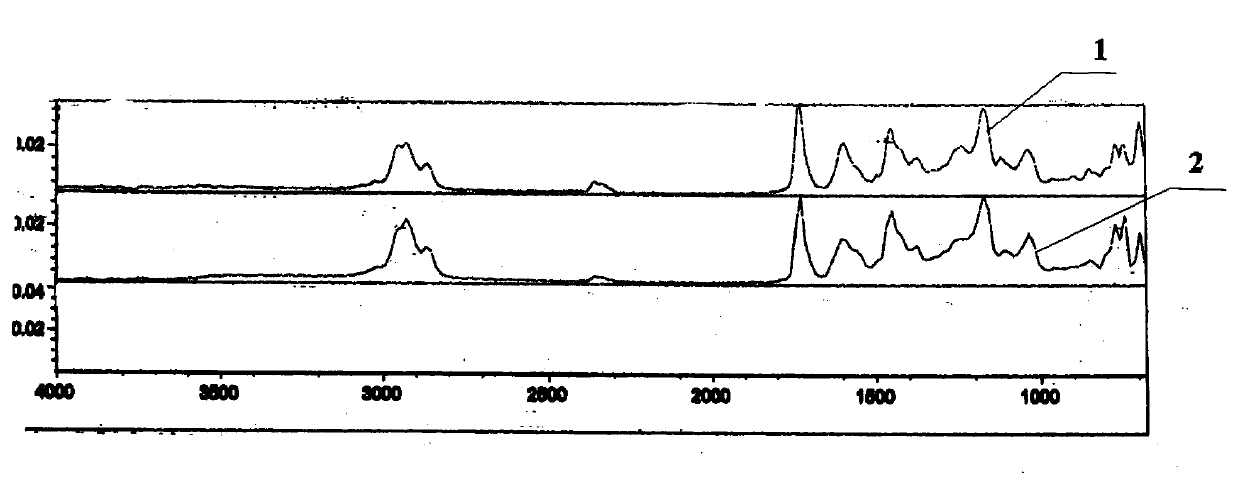

Image

Examples

Embodiment 1

[0035] The synthetic method of zinc acrylate resin in the present embodiment may further comprise the steps:

[0036] 1) Put the solvent and zinc-containing compound into the reaction kettle first, and raise the temperature to 120-135°C, and keep reflux;

[0037] 2) Then add the mixture of acrylic acid monomer, rosin and part of the initiator in the reactor, and add it dropwise into the reactor;

[0038] 3) After the dropwise addition is completed, react for 1 hour, then add the remaining part of the initiator, and continue the insulation reaction to form a resin.

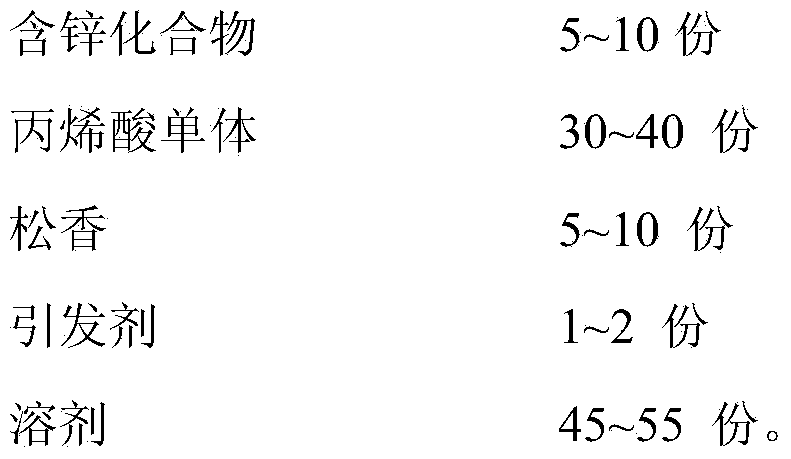

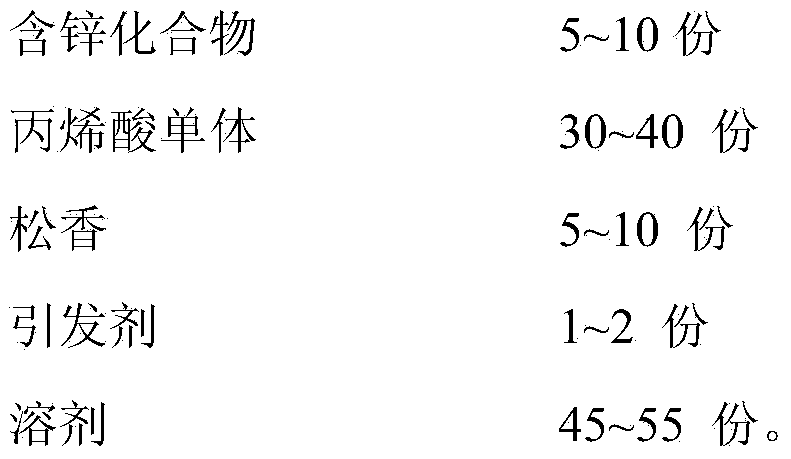

[0039] The proportioning ratio of each raw material component in embodiment 1 is shown in table 1.

[0040] The zinc acrylate resin obtained in this embodiment is a transparent yellow liquid, its acid value is 93mgKOH / g, solid content is 50.2%, viscosity: 180 seconds (coating-4 cups / 25 ℃), number average molecular weight is: 30815; The melting temperature is 42°C.

Embodiment 2

[0042] The synthetic method of zinc acrylate resin in the present embodiment may further comprise the steps:

[0043] 1) Put the solvent and zinc-containing compound into the reaction kettle first, and raise the temperature to 120-135°C, and keep reflux;

[0044] 2) Then add the mixture of acrylic acid monomer, rosin and part of the initiator to the reactor, and add it dropwise to the reactor;

[0045] 3) After the dropwise addition is completed, react for 1 hour, then add the remaining part of the initiator, and continue the heat preservation reaction to form the resin

[0046] The proportioning ratio of each raw material component in embodiment 2 is as shown in table 1.

[0047] The zinc acrylate resin obtained in the present embodiment is a transparent yellow liquid, its acid value is 89mgKOH / g, solid content is 51.8%, viscosity: 180 seconds (coating-4 cups / 25 ℃), number average molecular weight is: 48900; The melting temperature is 50°C.

[0048] Table 1

[0049]

...

Embodiment 3

[0052] The synthetic method of zinc acrylate resin in the present embodiment may further comprise the steps:

[0053] 1) Put the solvent and zinc-containing compound into the reaction kettle first, and raise the temperature to 120-135°C, and keep reflux;

[0054] 2) Then add the mixture of acrylic acid monomer, rosin and part of the initiator, and drop it into the reactor;

[0055] 3) After the dropwise addition is completed, react for 1 hour, then add the remaining part of the initiator, and continue the insulation reaction to form a resin.

[0056] The proportioning ratio of each raw material component in embodiment 3 is as shown in table 2.

[0057] The zinc acrylate resin obtained in this embodiment is a transparent yellow liquid, its acid value is 78mgKOH / g, solid content is 49.5%, viscosity: 180 seconds (coating-4 cups / 25 ℃), number average molecular weight is: 42760; The melting temperature is 47°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com