Growth method and application of rare earth orthoferrite single crystal

A technology of orthoferrite and growth method, which is applied in the preparation of rare earth element iron oxide functional materials and the preparation of ferromagnetic metal oxide functional materials, can solve the problem of affecting device performance and affecting the physical properties of rare earth orthoferrite single crystal materials , Difficult to fix problems such as crystals, to achieve the effect of high crystal quality, good crystal integrity, and high crystal growth efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

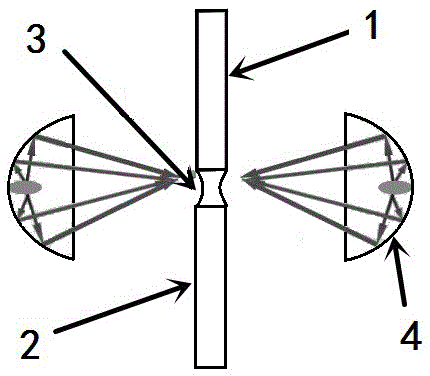

Method used

Image

Examples

Embodiment 1

[0021] In this example, Gd 0.9 La 0.1 FeO 3 A method for growing a single crystal, comprising the steps of:

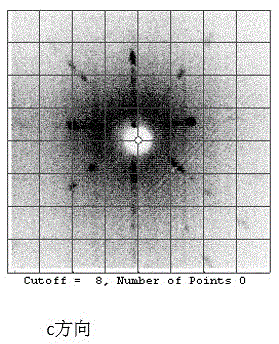

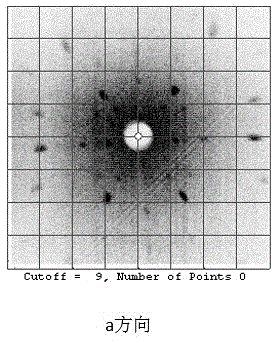

[0022] a. First, Gd with a purity of 99.99% 2 o 3 and La 2 o 3 and Fe 2 o 3 Weigh and accurately mix according to the specified molar ratio, put the mixed powder in an agate mortar and grind it for 8 hours to mix evenly, the first pre-calcination is kept in the air at 800°C for 12 hours, and naturally cool down to room temperature with the furnace to prepare Gd and polycrystalline powder of La rare earth elements and iron oxides; then put it back in an agate mortar and grind it fully, then put the polycrystalline powder into a mold, and press the fully ground powder into a diameter of 25mm under a pressure of 20MPa And the polycrystalline material wafer blank with a thickness of 4 mm is sintered for the second time in a high-temperature furnace at a temperature of 1300 ° C, and kept for 24 hours to obtain a polycrystalline material wafer; then the polycrystalli...

Embodiment 2

[0028] This embodiment is basically the same as Embodiment 1, especially in that:

[0029] In this example, HoMn 0.05 Fe 0.95 o 3 A method for growing a single crystal, comprising the steps of:

[0030] a. First, the Ho element oxide with a purity of 99.99% and Mn 2 o 5 and Fe 2 o 3 Weigh and accurately mix according to the specified molar ratio, put the mixed powder in an agate mortar and grind it thoroughly for 8 hours and mix evenly. The first pre-calcination is kept at 800°C in the air for 12 hours, and it is naturally cooled down to room temperature with the furnace to prepare Ho Polycrystalline powder of element oxides, Mn oxides and iron oxides; then put it back in an agate mortar and grind it fully, then put the polycrystalline powder into a mold, and press the fully ground powder under a pressure of 20MPa Form a polycrystalline wafer blank with a diameter of 20 mm and a thickness of 4 mm, and then sinter the second time in a high-temperature furnace at a temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com