Industrial factory building outer wall and mounting process thereof

A technology for industrial workshops and installation processes, applied to walls, building components, buildings, etc., can solve problems such as high transportation costs, deformation of four corners of boards, and tearing of thin-walled steel sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

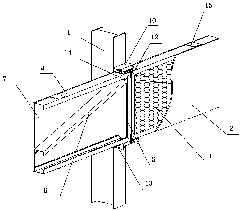

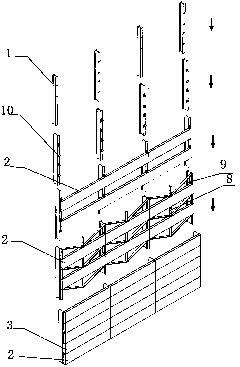

[0108] An exterior wall of an industrial factory building, comprising a main structure column 1, a support 10, a prefabricated wall panel 2 and an on-site assembled wall panel 3; the installation relationship of the prefabricated wall panel 2, the support 10 and the main structure column 1 is as follows figure 1 As shown, the four corners of the prefabricated wall panel 2 are respectively connected with the support 10, and the support 10 is connected with the column 1 of the main structure. Corner piece 19; the displacement connection plate 24 of the upper corner piece 18 is connected with the upper support 16, and the displacement connection plate 25 of the lower corner piece 19 is connected with the lower support 17.

[0109] In this embodiment, the on-site assembly wall panel 3 is installed between the upper and lower layers of the prefabricated wall panel 2 .

[0110] In this embodiment, the upper corner protector 18 is an L-shaped corner protector with a displacement conn...

Embodiment 2

[0137] An installation process for an exterior wall of an industrial factory building, comprising the following steps:

[0138] A. Install the support 10: install the support 10 on the column 1 of the main structure;

[0139] B. Install prefabricated wall panels 2: install prefabricated wall panels 2 on the main structure column 1 in step (A); the four corners of the prefabricated wall panels 2 are respectively connected with the support 10 on the main structure column 1; the prefabricated wall panels 2 There are corner protectors connected, and the corner protectors include an upper corner protector and a lower corner protector; the displacement connecting plate of the upper corner protector is connected with the upper support 10, and the displacement connecting plate of the lower corner protector is connected with the lower corner protector The supporting bracket 10 is connected; each layer of prefabricated wall panels 2 has a gap between the upper and lower sides, so as to ...

Embodiment 3

[0160] The exterior wall of the industrial factory building in this embodiment is basically the same as that in Embodiment 1, the difference is:

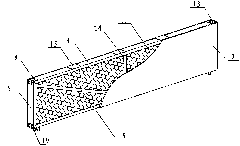

[0161] In this embodiment, the reinforcing rib I6 is a support bar and a tensile bar, and the auxiliary rib I5 is three parallel auxiliary ribs I5, and divides the upper and lower main ribs I4 into two parts, and each part has two Reinforcing rib I6, two reinforcing ribs I6 in each part are cross-connected, the main rib I4, auxiliary rib I5, and reinforcing rib I6 form shape connection, such as Figure 15 shown.

[0162] In this embodiment, the support 10 is connected to the main structure column 1 by welding.

[0163] In this embodiment, the four corners of the prefabricated wall panels 2 are connected to the corner protectors by welding.

[0164] In this embodiment, the main rib I4, the auxiliary rib I5 and the reinforcing rib I6 are connected by welding through the gusset plate 14.

[0165] In this embodiment, the panel 7 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com