Device for automatically identifying and tracking multi-layer and multi-pass welding beads

A multi-layer multi-pass, automatic identification technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problem of single-stripe difficult to identify multi-layer multi-pass welding, achieve simple structure, eliminate hysteresis, improve real-time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

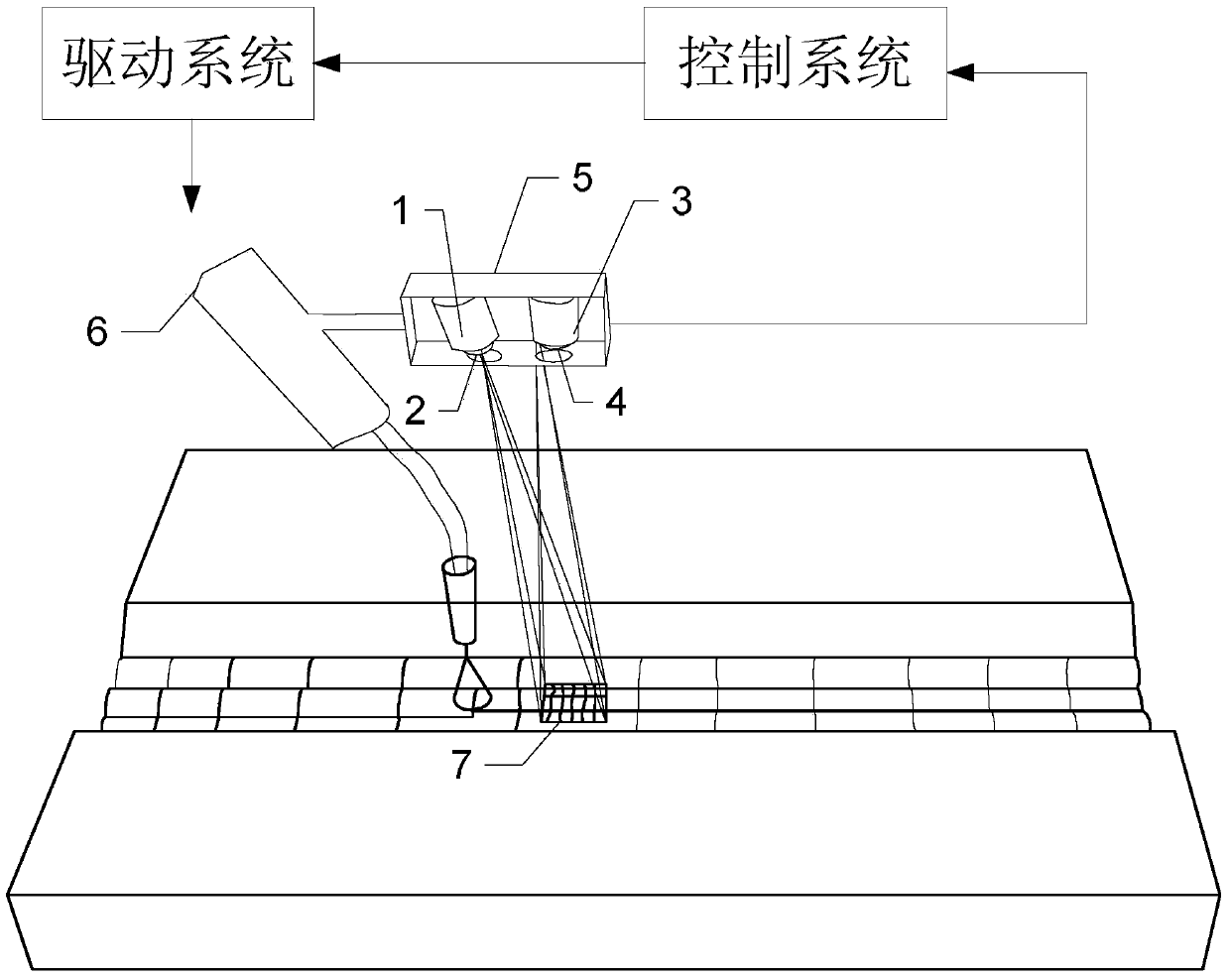

[0013] Specific implementation mode one: combine figure 1 Describe this embodiment, the device for automatic identification and tracking of multi-layer multi-run welds described in this embodiment, which includes a laser 1, a diffractive optical element 2, an image acquisition system, a control system, a drive system and a welding torch 6;

[0014] The cylindrical light emitted by the laser 1 is incident on the diffractive optical element 2, and the light passing through the diffractive optical element 2 forms a grid structured light, and the grid structured light is incident on the welding bead in front of the welding area. The image acquisition system is used to collect multiple The grid structured light and weld image on the multi-layer welding bead, the data collection output terminal of the image acquisition system is connected with the data collection input terminal of the control system, the welding torch 6 position and attitude control signal output terminal of the cont...

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment is a further limitation of the device for automatic identification and tracking of multi-layer multi-run welds described in Embodiment 1. The image acquisition system includes a camera 3 and a narrow-band filter 4;

[0023] The narrow-band filter 4 is installed in front of the lens of the camera 3, and the output end of the acquisition signal of the camera 3 is connected with the input end of the acquisition signal of the control system.

[0024] The narrow band filter 4 is used to reduce arc interference.

specific Embodiment approach 3

[0025] Specific embodiment three: This embodiment is a further limitation of the device for automatic identification and tracking of multi-layer multi-run welds described in specific embodiment two, and the control system includes the following modules:

[0026] A module for receiving image data;

[0027] A module for performing data processing on the received image data;

[0028] A module for calculating the processed data to obtain welding seam trajectory information and welding torch 6 deviation information;

[0029] A module for outputting control signals for driving the position and posture of the welding torch 6 to the drive system according to the obtained welding seam track information and welding torch 6 deviation information.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com